Deuterium-deuterium controllable compensating neutron well logging instrument during drilling

A technology for compensating neutrons and logging tools, which is applied in earthwork drilling, boreholes/well components, etc., can solve problems such as radioactive hazards, poor sensitivity, and low service life of reaction accelerator neutron sources, and achieve reduced radioactive hazards and high Effect of Lifetime and Sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

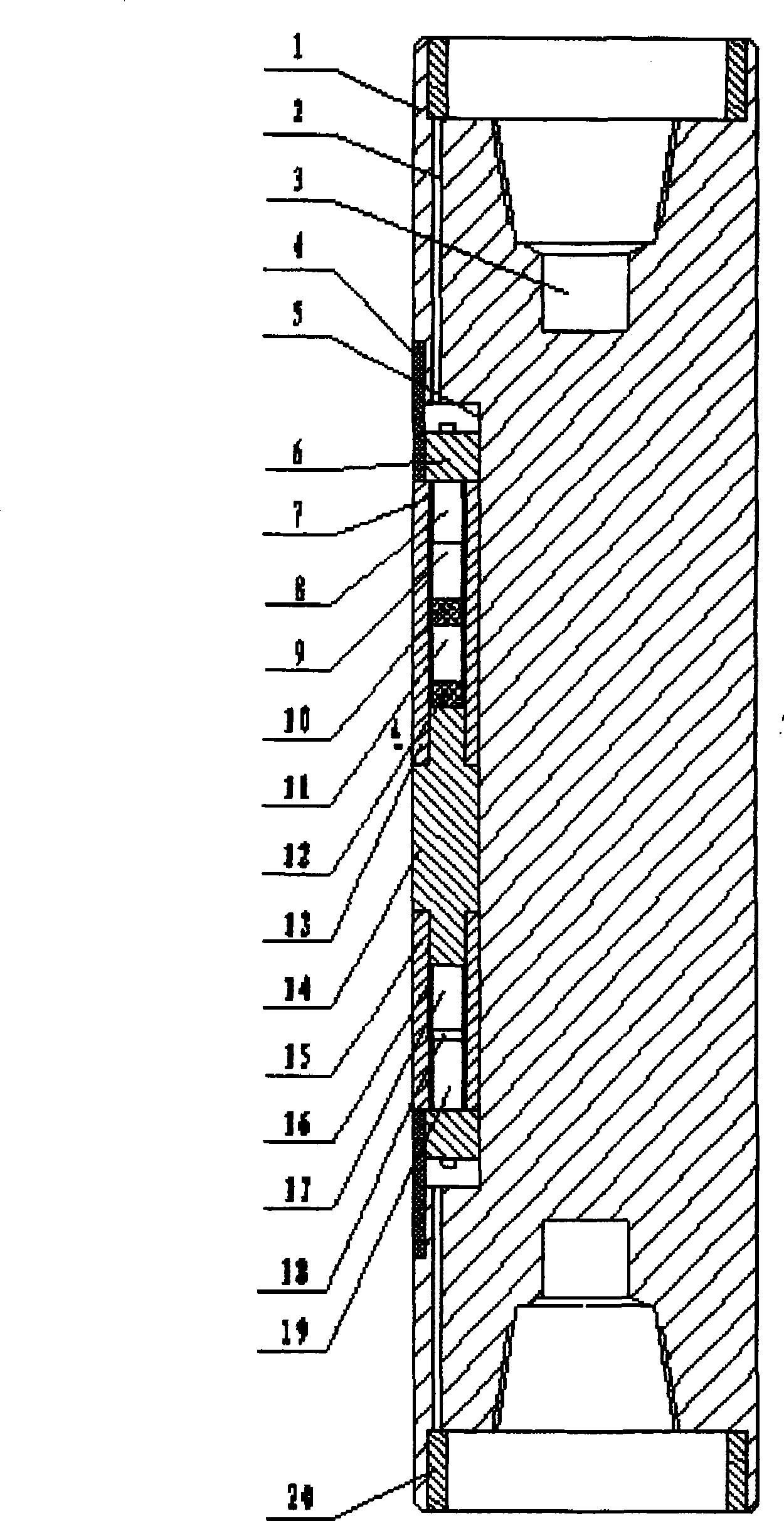

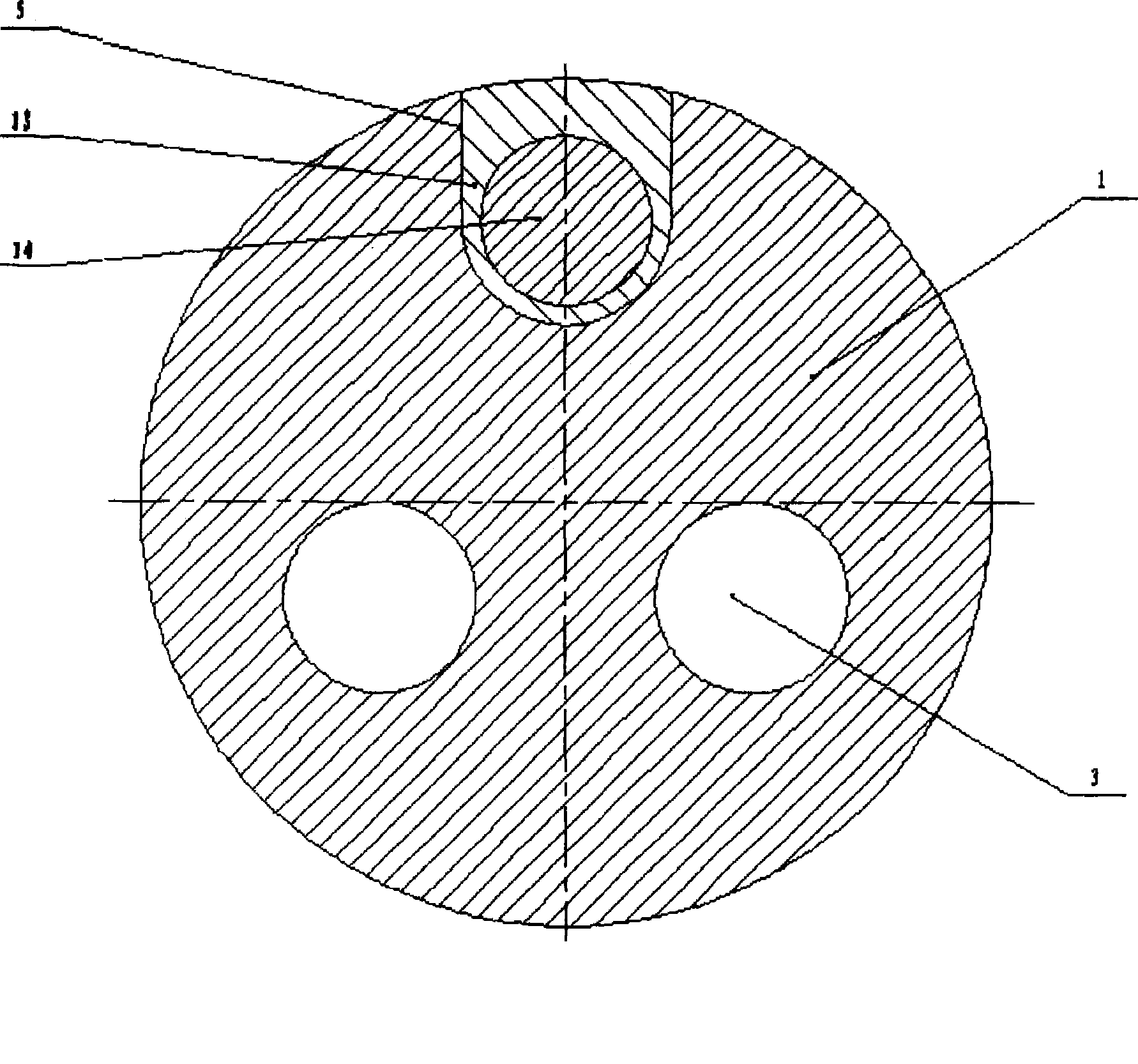

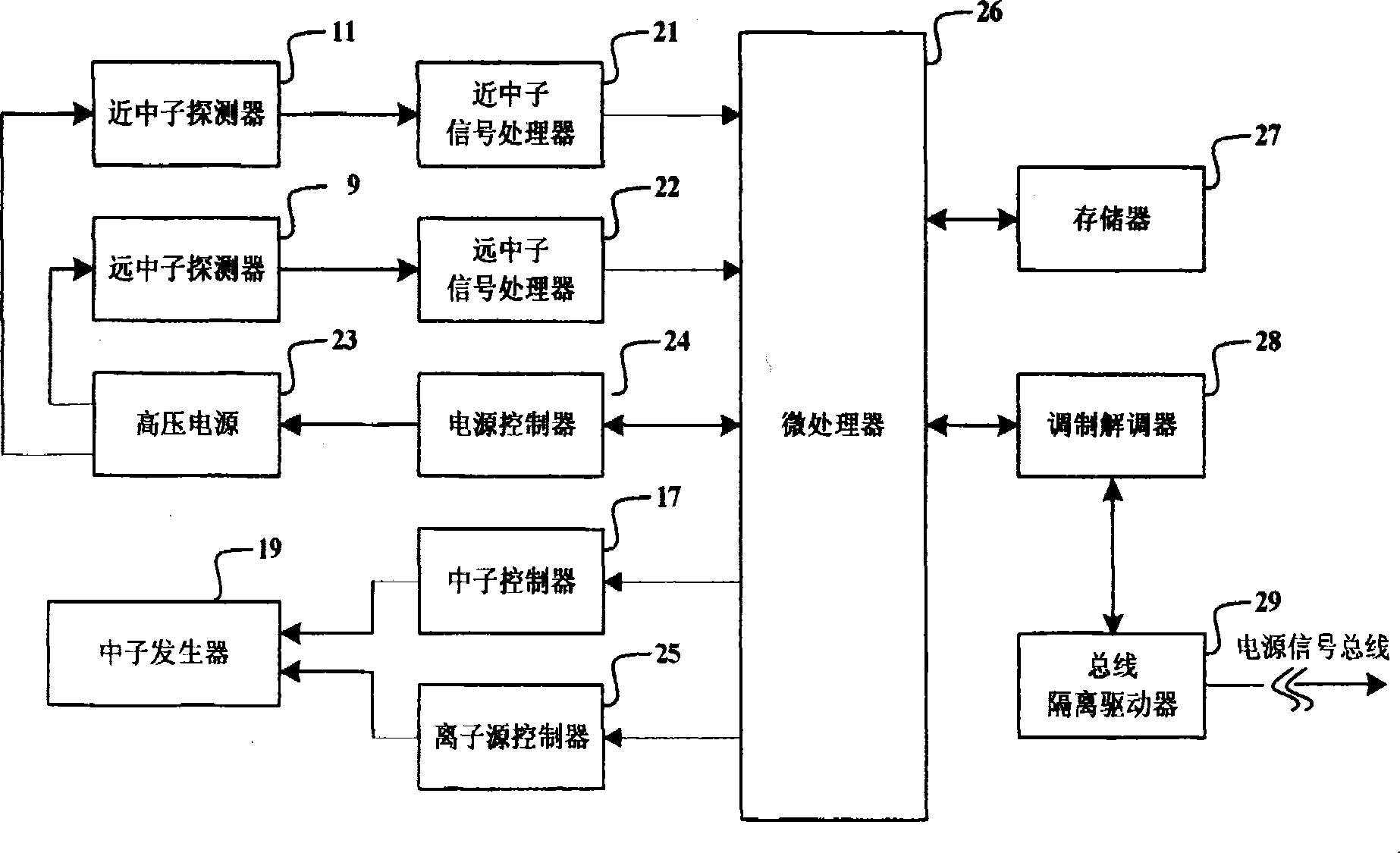

[0027] Now combined with the manual figure 1 , 2 and 3, the present invention is further described.

[0028] figure 1 Represents an axial section view of the instrument. In order to adapt to the harsh working environment underground, the instrument adopts a drill collar installation structure, and has anti-vibration and anti-high pressure measures. The drill collar 1 is used as the installation skeleton of the instrument and a part of the downhole drilling tool, and is usually located behind the drill bit or the deflection tool. There is a U-shaped groove 5 on the side of the drill collar, and a receiver module anti-pressure cylinder 13 and a generator module anti-pressure cylinder 15 are installed in the U-shaped groove 5 from top to bottom, and their wall thickness should meet the requirements for resisting high pressure of downhole mud. It is required that the receiver module anti-pressure cylinder 13 and the generator module anti-pressure cylinder 15 are respectively e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com