Preparation method of polycrystalline vanadium dioxide film with room temperature resistance temperature coefficient higher than 10%K

A technology of temperature coefficient of resistance and vanadium dioxide, which is applied in the field of polycrystalline vanadium dioxide thin film preparation, can solve the problems of affecting device detection rate, high TCR, unusability, etc., achieve low grain boundary density, increase TCR, and increase activation energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

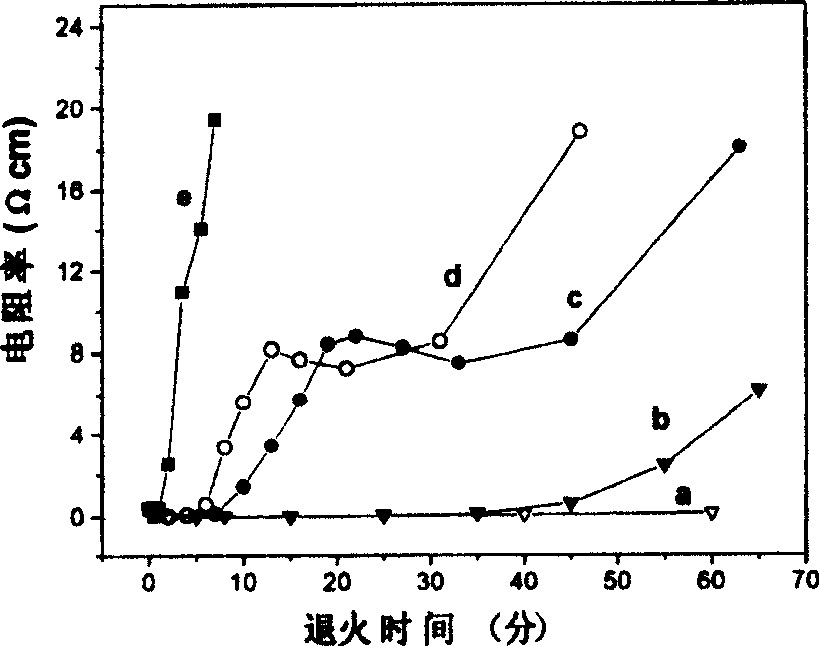

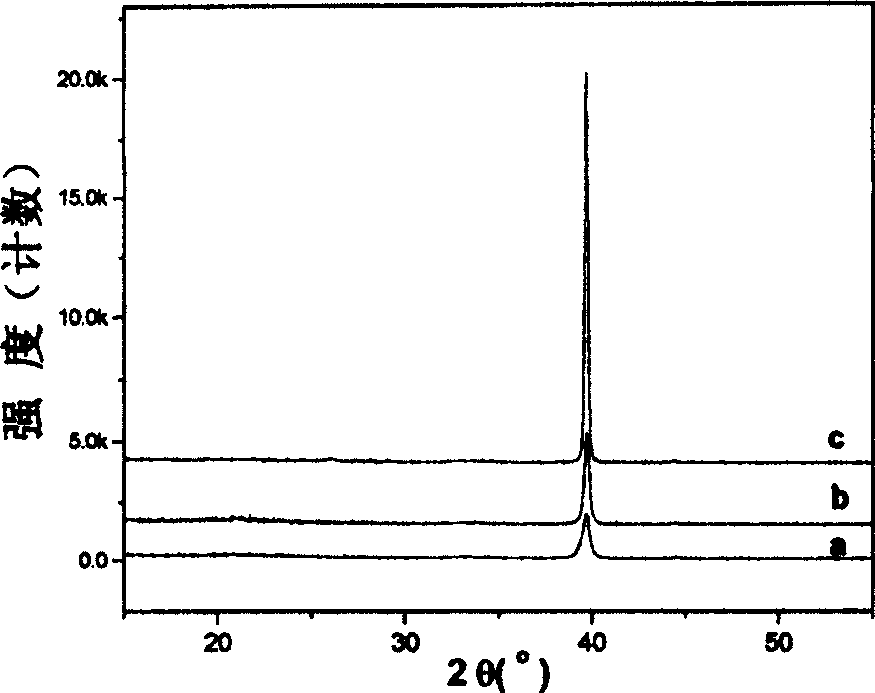

[0025] The preparation process of the embodiment of the present invention is as follows:

[0026] (1) Preparation of sputtering target

[0027] High-purity V with a purity of 99.99% 2 o 5 Powder and high purity Sb with a purity of 99.99% 2 o 3 、 Ta 2 o 5 、WO 3 、MoO 3 , MnO, Nb 2 o 5 The powder is uniformly mixed and ball milled at 100atm%: 1-15atm%. In order to prevent the introduction of impurities, agate balls and agate jars are used for ball milling, and the speed of ball milling is controlled at 40-60 revolutions per minute. at 100Kg / cm 2 The initial pressure molding, and then 2000Kg / cm 2 , 20 minutes of isostatic pressing to obtain a solid sputtering target. Finally, heat treatment in an air atmosphere in a box furnace with a heating rate of about 5°C / min at 300°C to 600°C, keep it at 600°C for one hour, cool down naturally to room temperature, and take it out for use.

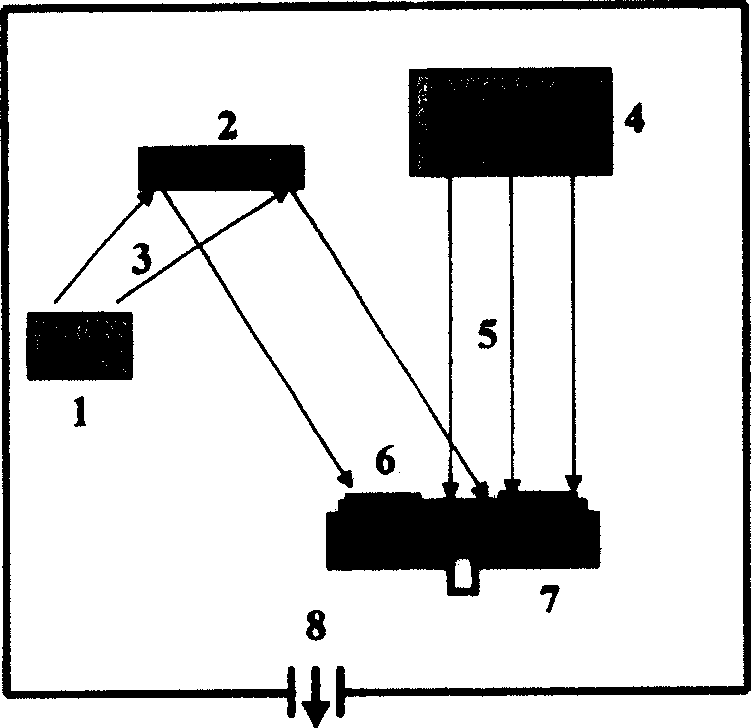

[0028] (2) Ion beam enhanced deposition

[0029] Sputter beam as Ar + , beam intensity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com