Substrate processing device and substrate processing system

A substrate processing device and substrate technology, applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve problems such as difficult to ensure installation space, achieve the effects of reduced area, easy maintenance operations, and suppressed floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

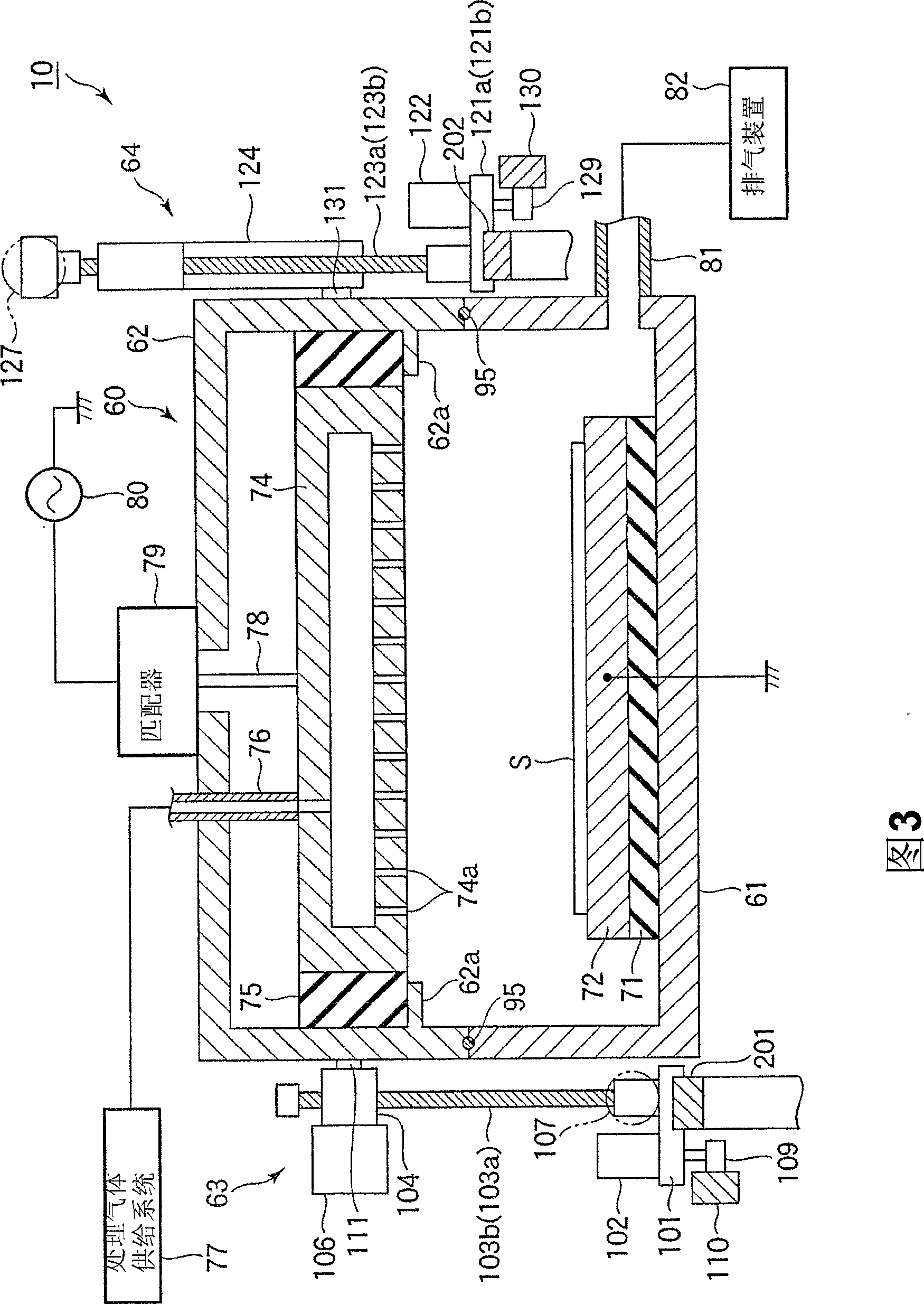

[0089] Here, the case where the substrate processing apparatus of the present invention is used in a multi-chamber vacuum processing system for etching a glass LCD substrate (hereinafter simply referred to as "substrate") S will be described.

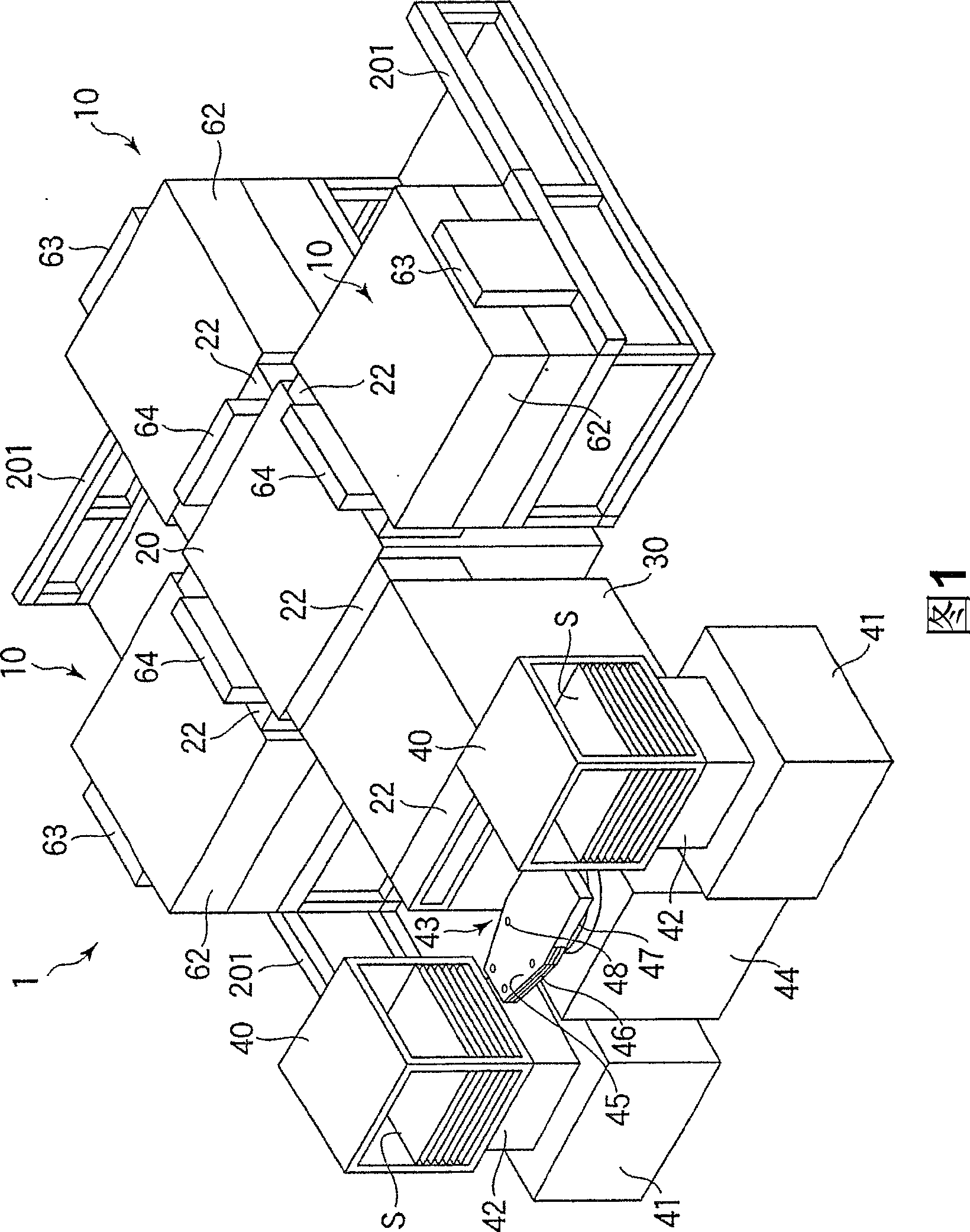

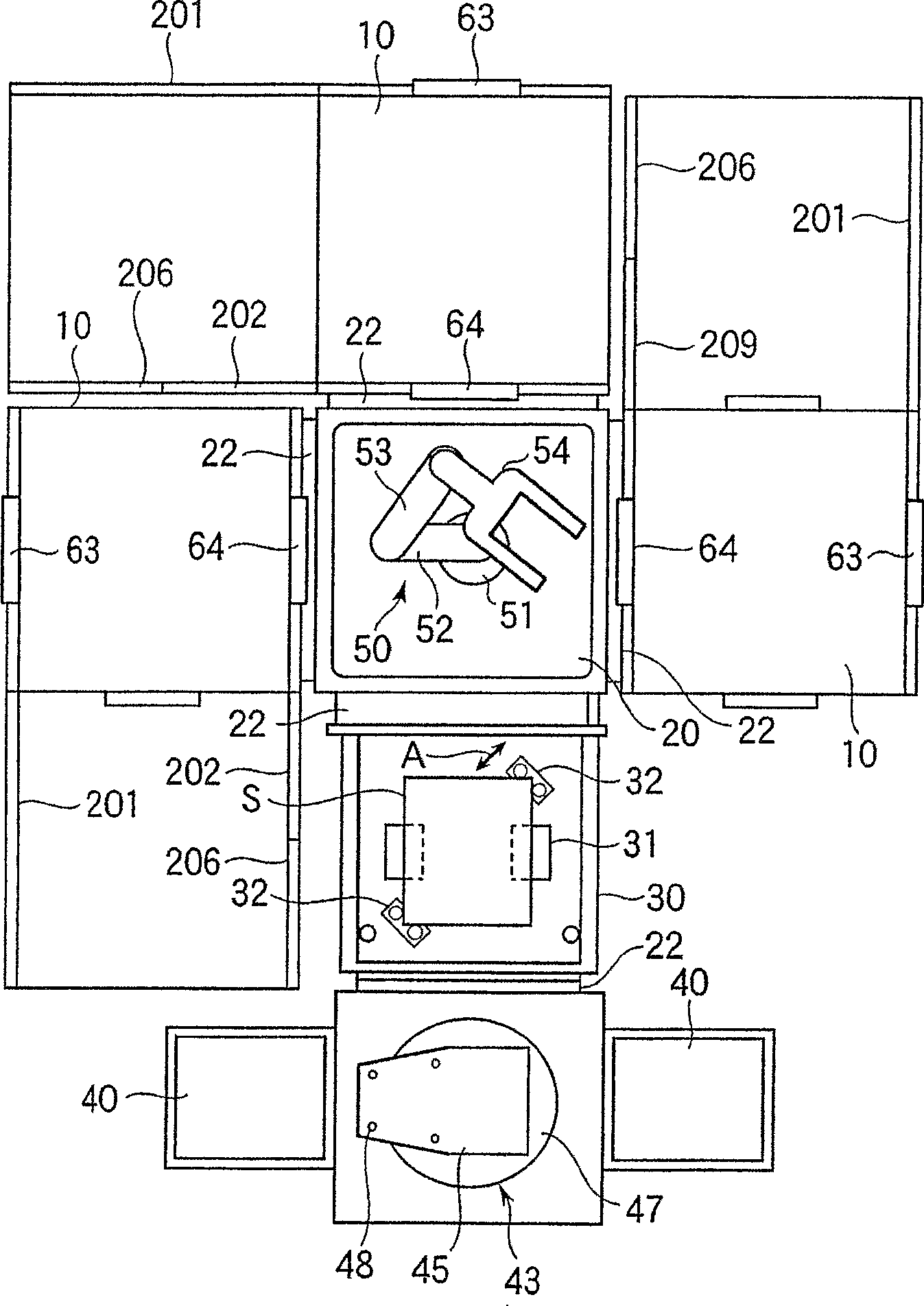

[0090] FIG. 1 is a schematic perspective view showing the vacuum processing system 1, figure 2 is a horizontal sectional view showing its interior. In this vacuum processing system 1, the central part is connected to the transfer chamber 20 and the load lock chamber 30 which are transfer units. Three etching processing apparatuses 10 are arranged around the transfer chamber 20 as processing modules. In addition, between the transfer chamber 20 and the load lock chamber 30, between the transfer chamber 20 and each etching processing apparatus 10, and on the openings communicating the load lock chamber 30 and the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com