Method for preventing charge generation of high voltage component machining process

A technology for process and high-voltage devices, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc. It can solve the problems of large leakage of isolation structure, inability to isolate, and low device turn-on voltage, and achieve high stability and device characteristics. Normal, stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

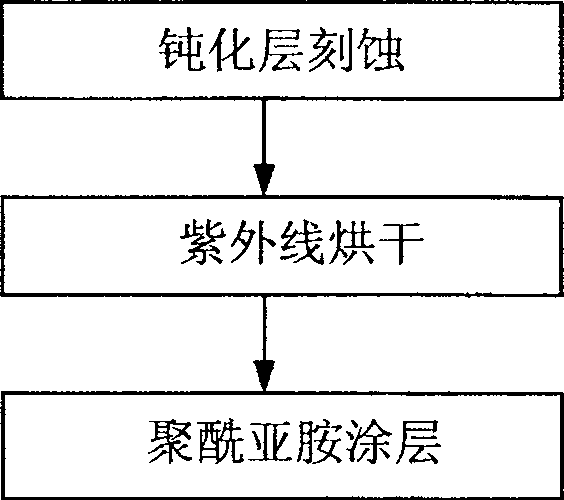

[0013] Aiming at the impact of charges on high-voltage devices, the present invention adopts the method of ultraviolet drying to release charges, that is, to use ultraviolet light energy to recombine the charges generated in various manufacturing processes (the energy of ultraviolet rays can neutralize the charges generated in the oxide layer). A large number of electron-hole pairs), so as to achieve the effect of releasing charges.

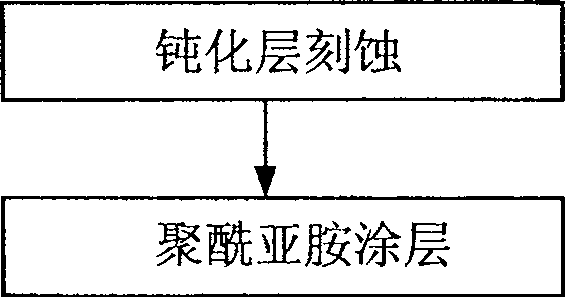

[0014] see figure 1 , 2 As shown, the ultraviolet drying described in the present invention needs to be carried out after the subsequent metal connection and the passivation layer are etched, especially after the passivation layer is etched, the effect is the best. Then followed by polyimide coating process. In the existing process, the polyimide coating process is directly performed after the passivation layer is etched.

[0015] When the method of the present invention is used for specific implementation, it is necessary to select an ultravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com