Shunting humidifying environmental protecting box

An environmental box and split-flow technology, applied in laboratory utensils, enclosures or chambers, chemical instruments and methods, etc., can solve the problems of reducing air temperature control accuracy, reducing humidification performance, reducing humidification effect, etc., to achieve enhanced controllability performance and control accuracy, high-precision humidification adjustment accuracy, and the effect of realizing humidification adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

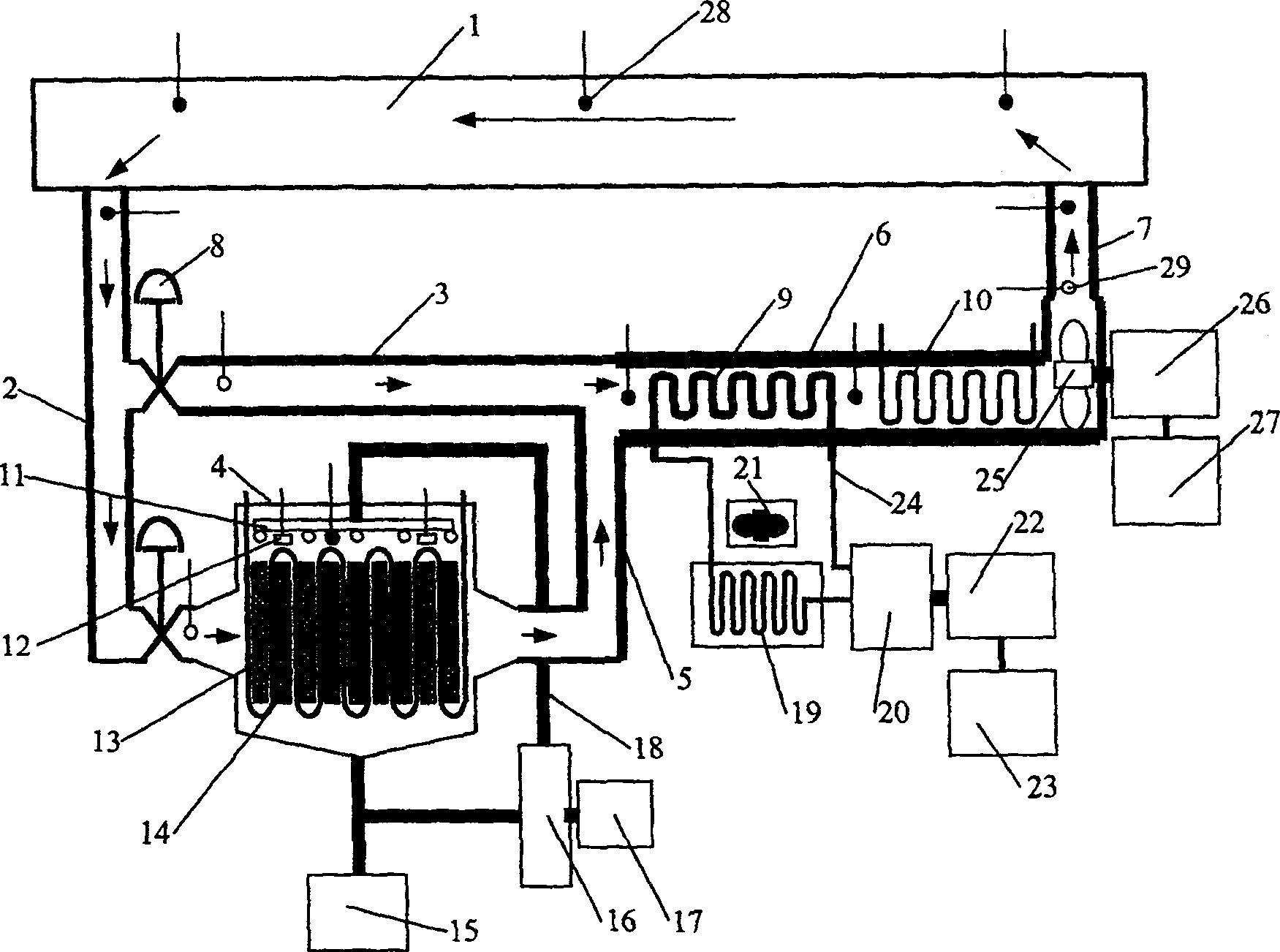

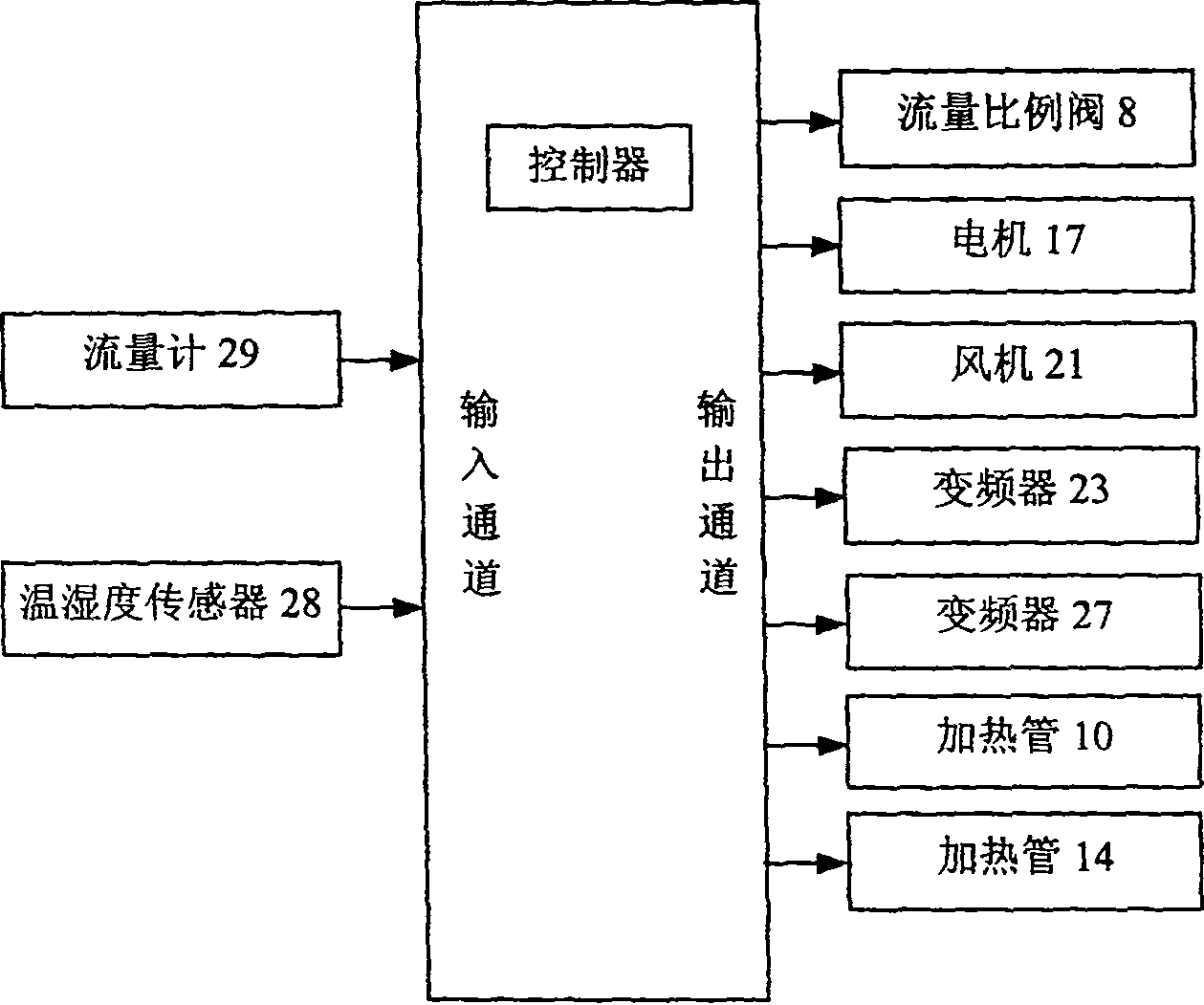

[0020] The invention provides a split-flow internal humidification type environmental box, the innovation of which is: the inner chamber is connected with the air inlet pipe and the air outlet pipe, and the flow ratio regulating valve connects the inlet pipe and the bypass pipe together, and the flow ratio is adjusted The valve connects the inlet pipe and the humidification chamber together, the connecting pipe connects the humidification chamber and the temperature control pipe together, and the air pump connects the temperature control pipe and the air outlet pipe together. The humidification chamber has a built-in heating type humidifier.

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0022] The structure of the shunt internal humidification type environmental box is as follows: figure 1 and figure 2 As shown, it includes inner chamber 1 and humidifying, evaporating, and condensing devices. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com