Rapid detecting method for detecting formaldehyde doped in flash milk

A detection method and formaldehyde technology are applied in the field of rapid detection of formaldehyde mixed in raw milk, which can solve the problems of unguaranteed raw milk quality, inconspicuous color development, difficult safe operation, etc., and achieves low cost, fast color reaction, Measuring the effect of relaxed conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] First weigh 12g of sodium hydroxide and dissolve it in 100mL of water to form a 12% sodium hydroxide solution; then weigh 1g of phloroglucinol and dissolve it in 100mL of 12% sodium hydroxide (NaOH) solution.

[0041] Add 3ml of raw milk sample directly into the test tube, then add 0.5ml of the above-mentioned mixed reagent, do not shake, and observe the color reaction at the bottom of the test tube visually within 1min.

[0042] It is best to make a blank test tube when testing, which will be conducive to comparative observation.

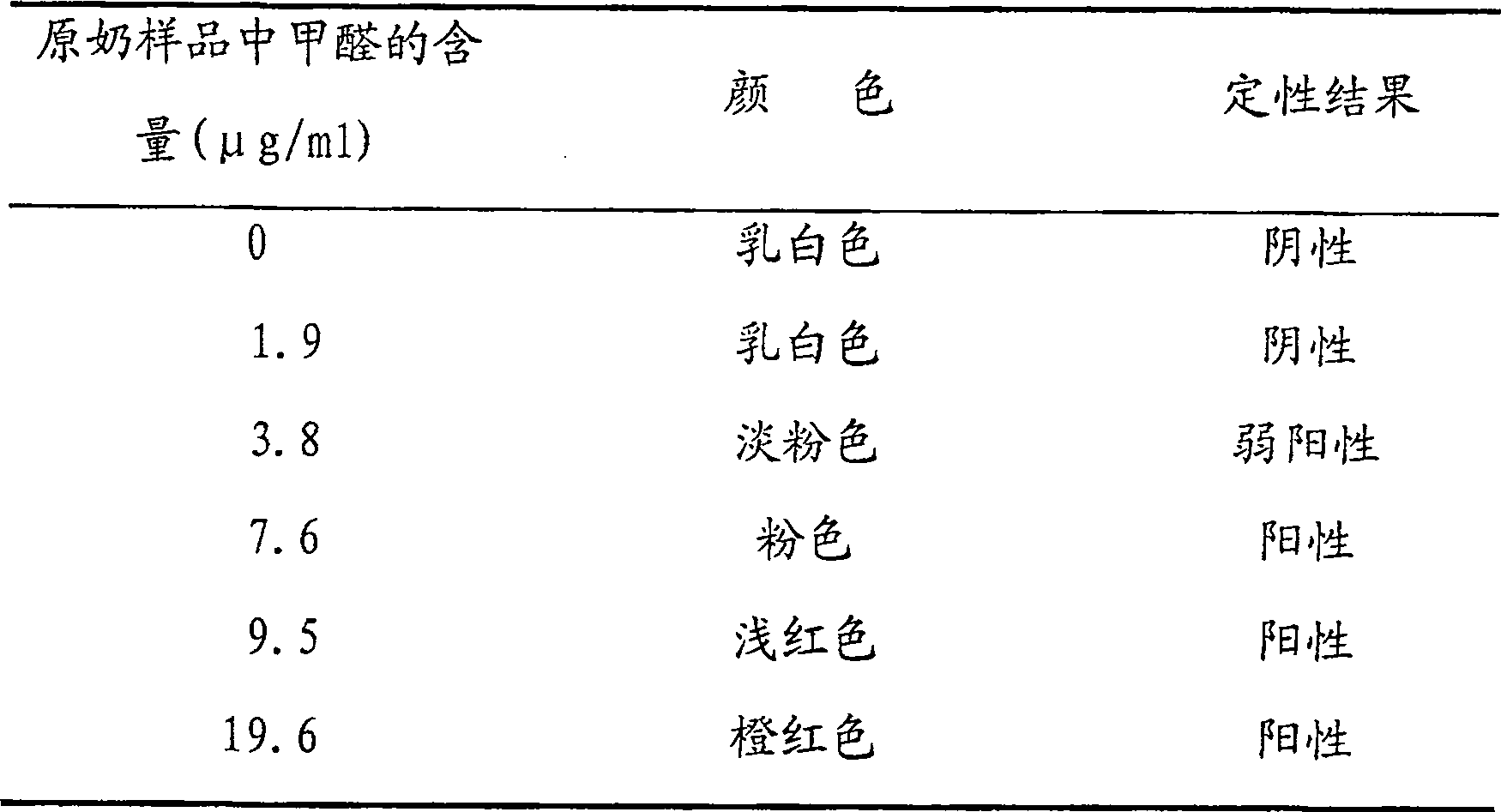

[0043] The test results are as follows:

[0044]

Embodiment 2

[0046] First weigh 14g sodium hydroxide and dissolve it in 100mL water to form a 14% sodium hydroxide solution; then weigh 0.5g phloroglucinol and dissolve it in 100mL 14% sodium hydroxide (NaOH) solution.

[0047] Add 8ml of raw milk sample directly to the test tube, then add 0.5ml of the above-mentioned mixed reagent, do not shake, and observe the color reaction at the bottom of the test tube visually within 1min.

[0048] It is best to make a blank test tube when testing, which will be conducive to comparative observation.

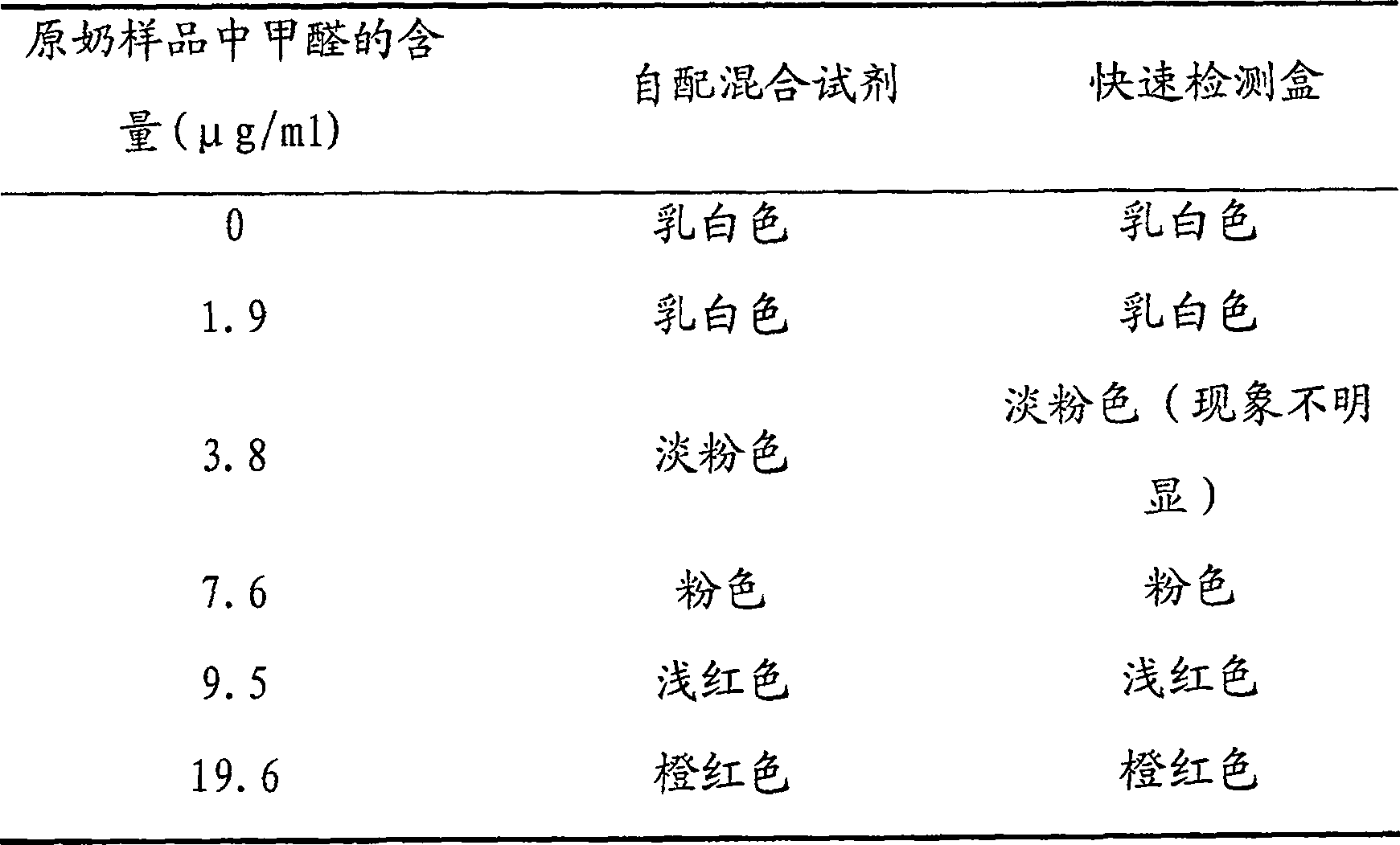

[0049] The test results are as follows:

[0050]

[0051]

Embodiment 3

[0053] First weigh 10g of sodium hydroxide and dissolve it in 100mL of water to form a 14% sodium hydroxide solution; then weigh 1.5g of phloroglucinol and dissolve it in 100mL of 10% sodium hydroxide (NaOH) solution.

[0054] Directly add 2ml of raw milk sample into the test tube, then add 0.5ml of the above-mentioned mixed reagent, do not shake, and observe the color reaction at the bottom of the test tube visually within 1min.

[0055] It is best to make a blank test tube when testing, which will be conducive to comparative observation.

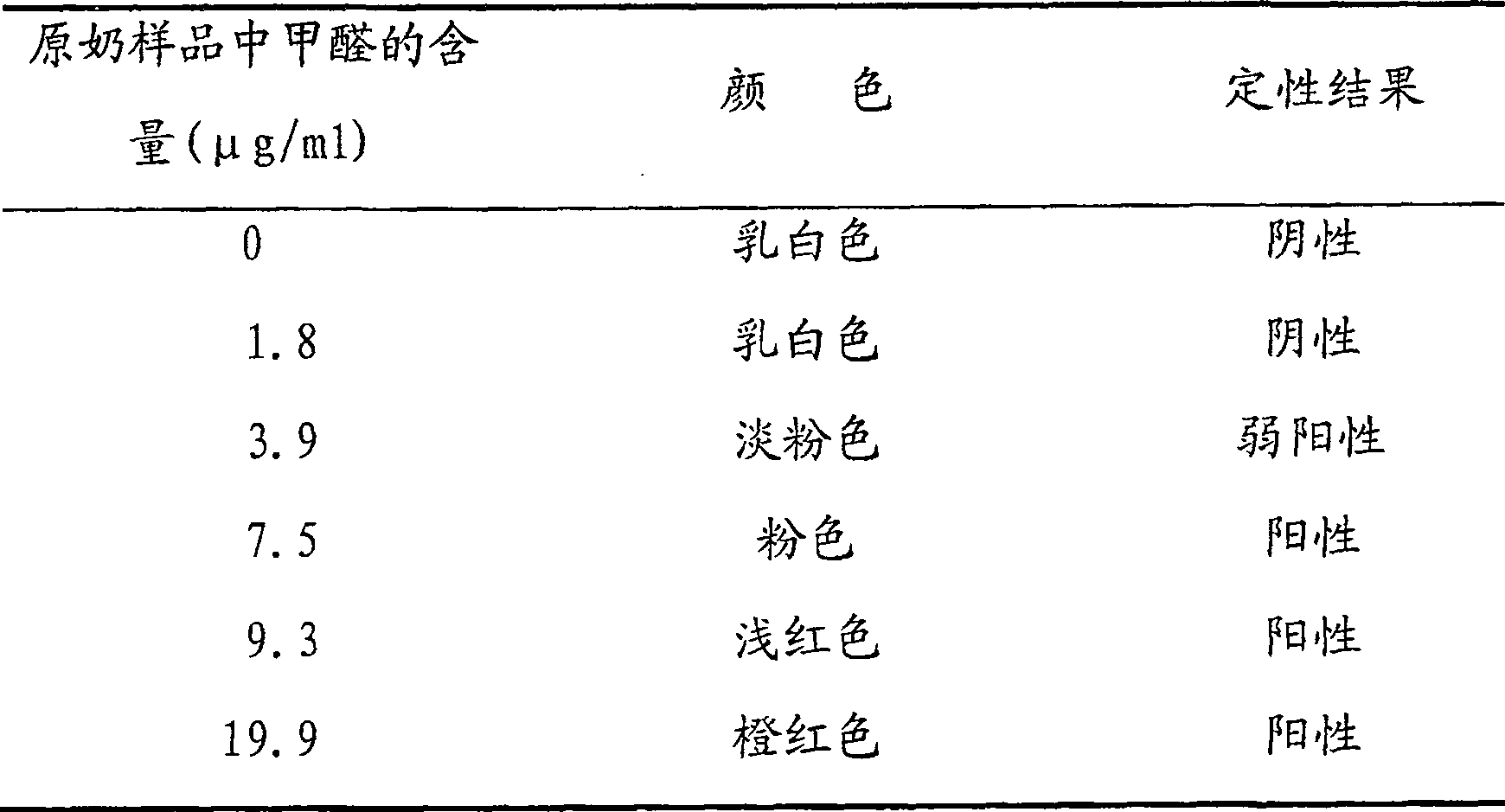

[0056] The test results are as follows:

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com