A preparation method and application of smart fabrics for information storage and hydrogen fluoride visual detection

An information storage, hydrogen fluoride technology, applied in the direction of material analysis by chemical reaction of materials, material analysis by observing the impact on chemical indicators, plant fibers, etc., can solve problems such as death, skin and bone damage, and achieve rapid Effects of color reaction, excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

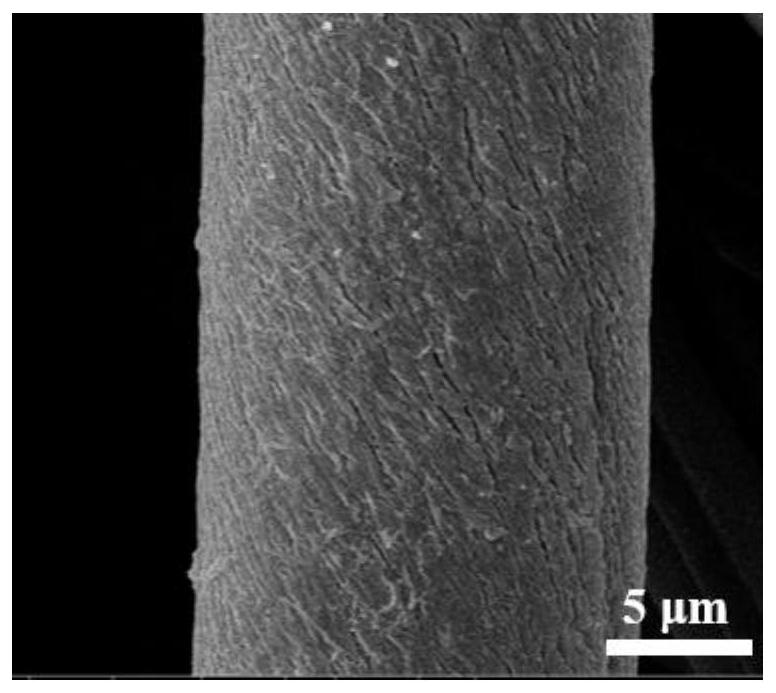

[0032] The purchased white pure cotton cloth was treated as follows: ultrasonically washed with deionized water for 15 minutes, then ultrasonically washed with ethanol for 15 minutes, and ultrasonically washed with acetone for 5 minutes. .

[0033] The azophenylmaleimide and the solvent are prepared into a polymer solution according to 1 g: 55 g, and the solvent is dimethyl sulfoxide.

[0034] Spinning is carried out with a uniaxial electrospinning device, which consists of a high-voltage power supply, an extrusion injection device and a receiving device. The spinning solution was loaded into a syringe with a volume of 2.5 mL, and the inner diameter of the syringe needle was 0.24 mm. Connect the positive pole of the high-voltage power supply to the pin header, and the receiving board to the ground wire. The spinning voltage was 16 kV, the flow rate of the spinning solution was 0.11 mL / h, the receiving distance was 15 cm, and the indoor relative humidity was 30%. The prepare...

Embodiment 2

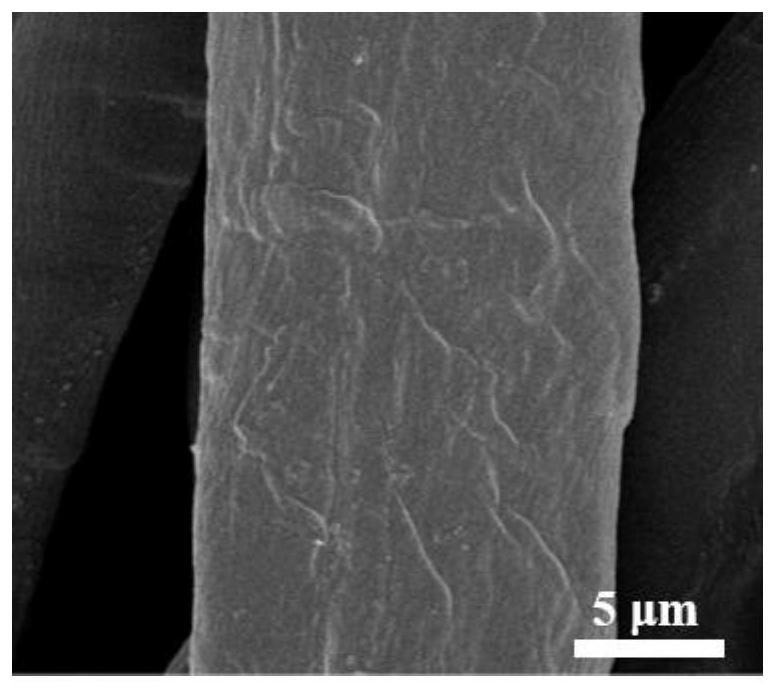

[0037] The purchased white pure cotton cloth was treated as follows: ultrasonically washed with deionized water for 20 minutes, then ultrasonically washed with countless ethanol for 10 minutes, and ultrasonically washed with acetone for 20 minutes. After taking it out, it was dried in an oven at a specific temperature of 60 °C and a time of 6 hours. .

[0038] The azophenylmaleimide and the solvent are prepared into a polymer solution according to 1g:100g, and the solvent is chloroform.

[0039] The spinning solution was loaded into a syringe with a volume of 2.5 mL, and the inner diameter of the syringe needle was 0.24 mm. Connect the positive pole of the high-voltage power supply to the pin header, and the receiving board to the ground wire. The spinning voltage was 18 kV, the flow rate of the spinning solution was 0.1 mL / h, the receiving distance was 18 cm, and the indoor relative humidity was 28%. The prepared smart fabrics were placed in an oven at 80 °C to dry, so that...

Embodiment 3

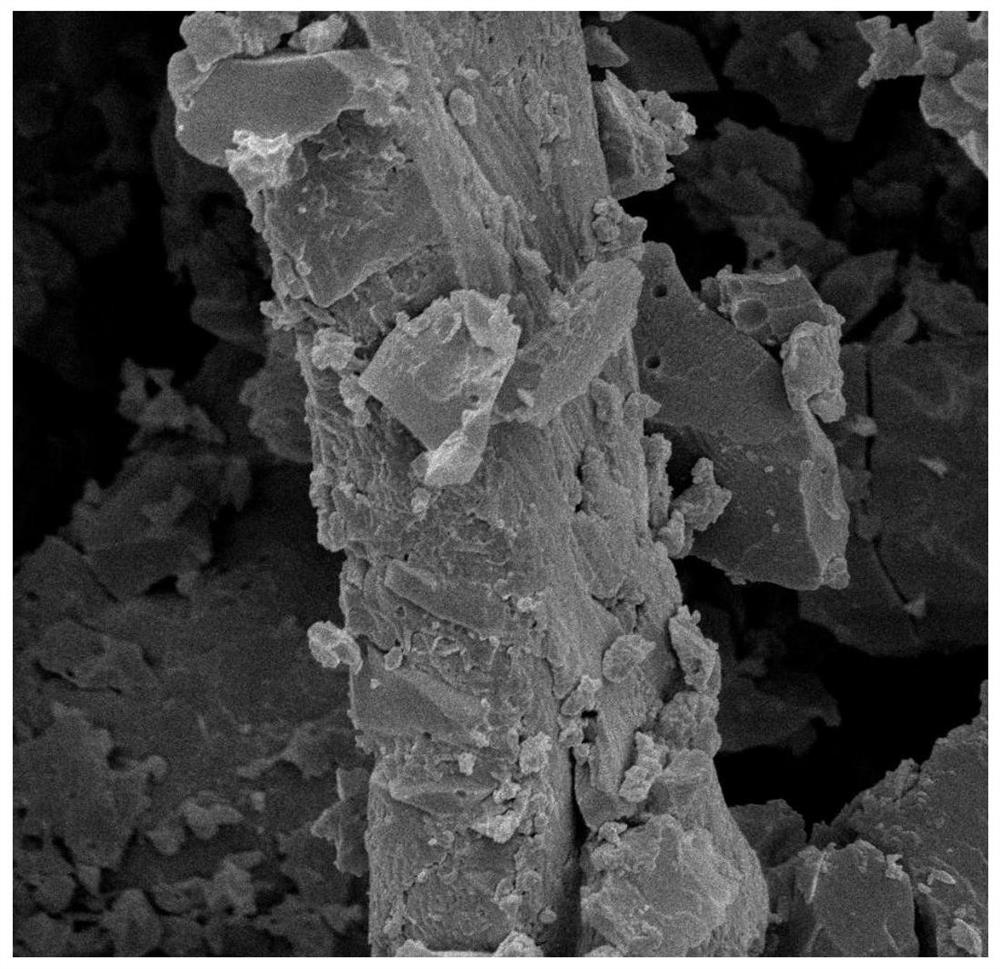

[0041] The purchased white cotton cloth was treated as follows: ultrasonically washed with deionized water for 10 minutes, then ultrasonically washed with countless ethanol for 20 minutes, and ultrasonically washed with acetone for 10 minutes. After taking it out, it was dried in an oven at a specific temperature of 100 °C and a time of 6 hours. .

[0042] The azophenylmaleimide and the solvent are prepared into a polymer solution according to 1g:10g, and the solvent is N,N-dimethylformamide.

[0043] The spinning solution was loaded into a syringe with a volume of 2.5 mL, and the inner diameter of the syringe needle was 0.24 mm. Connect the positive pole of the high-voltage power supply to the pin header, and the receiving board to the ground wire. The spinning voltage was 17kV, the flow rate of the spinning solution was 0.12mL / h, the receiving distance was 15cm, and the indoor relative humidity was 38%. The prepared smart fabric was placed in an oven at 110 °C to dry, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com