Parallel mechanism with four degrees of freedom

A degree of freedom, parallel technology, used in manipulators, program-controlled manipulators, metal processing mechanical parts, etc., can solve the problems of small workspace and mechanism, high manufacturing cost, complex structure, etc., to achieve good rigidity, low manufacturing cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

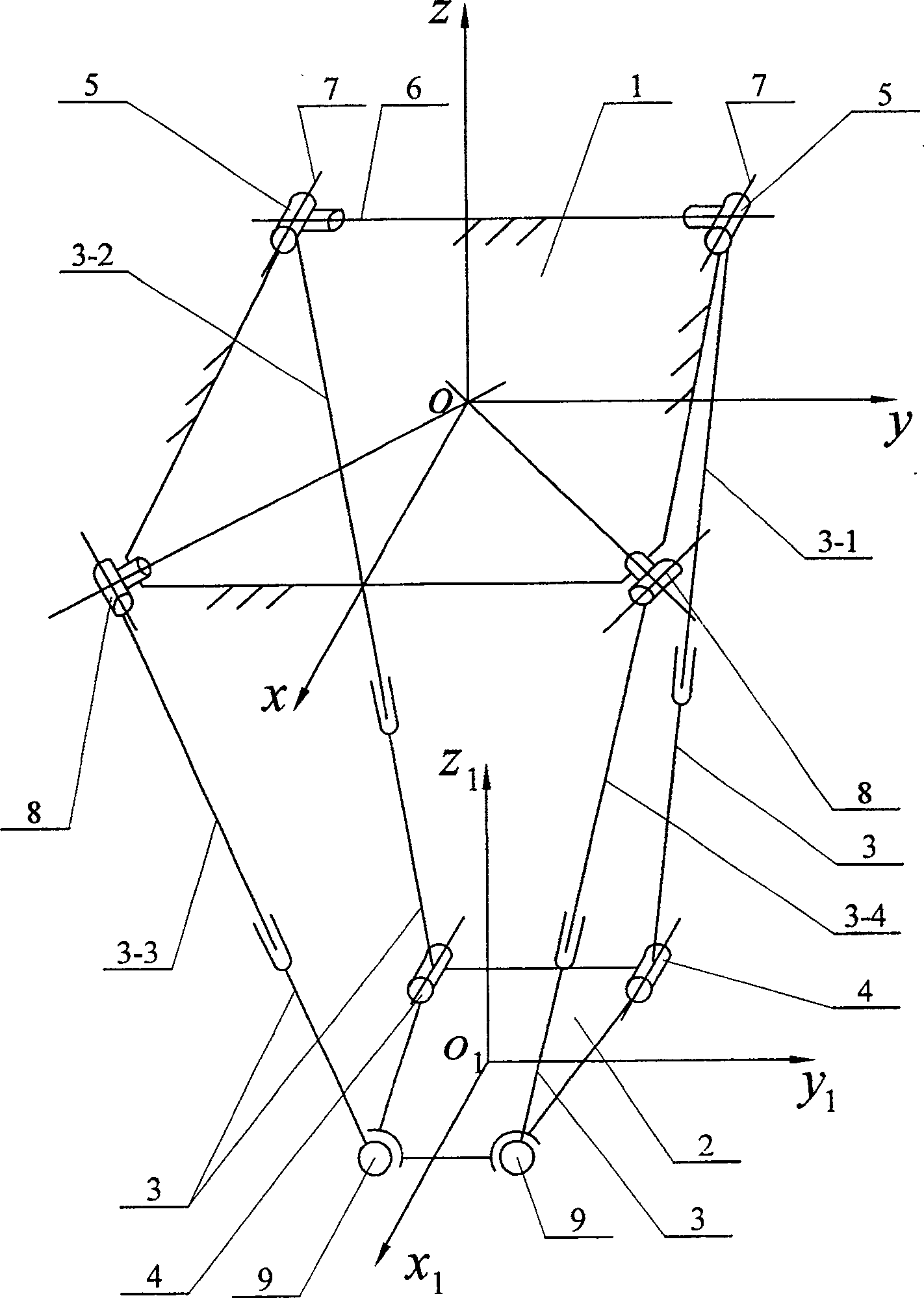

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is made up of fixed platform 1, moving platform 2 and four telescopic links 3; The upper ends of described four telescopic links 3 are hinged with fixed platform 1 respectively, and the The lower ends of the first telescopic connecting rod 3-1 and the second telescopic connecting rod 3-2 are respectively connected with the motion platform 2 through the respective rotating pairs 4, the third telescopic connecting rod 3-3 and the third telescopic connecting rod 3 in the four telescopic connecting rods 3 The lower ends of the fourth telescopic link 3-4 are respectively hinged with the motion platform 2.

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the upper end of the first telescopic link 3-1 and the upper end of the second telescopic link 3-2 of this embodiment are respectively hinged to the fixed platform 1 through the respective first Hooke hinges 5, the two The primary rotary axis 6 of the first Hooke hinge 5 is parallel to the Y axis, the secondary rotary axis 7 of the two first Hooke hinges 5 is parallel to the X axis, and the X axis and the Y axis are perpendicular to each other, ( The establishment of the coordinate system is: the Y-axis is parallel to the first-order rotary axis 6 directions of the two first Hooke hinges 5, the X-axis is in the plane of the fixed platform 1, and the Z-axis is perpendicular to the X-axis and the Y-axis respectively), so The upper end of the third telescopic connecting rod 3-3 and the upper end of the fourth telescopic connecting rod 3-4 are respectively hinged with the fixed platform 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com