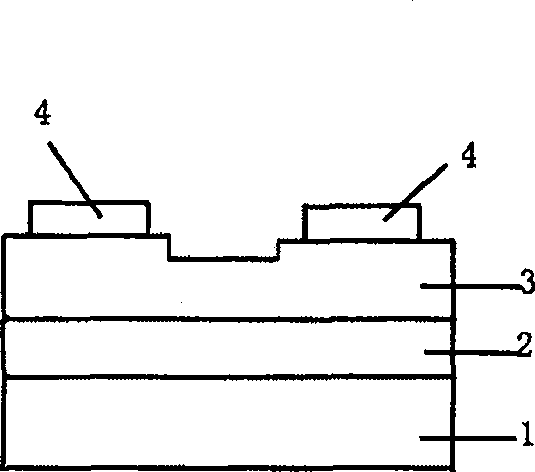

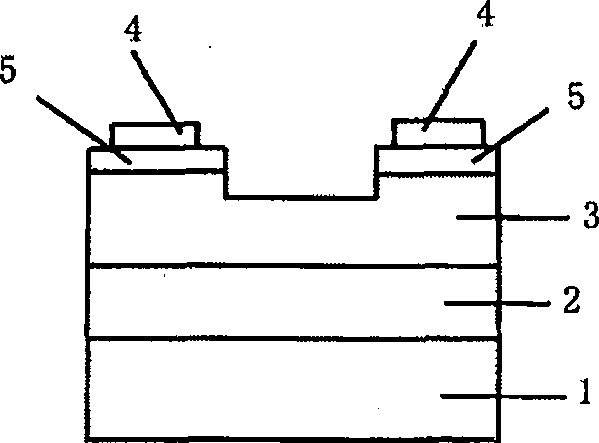

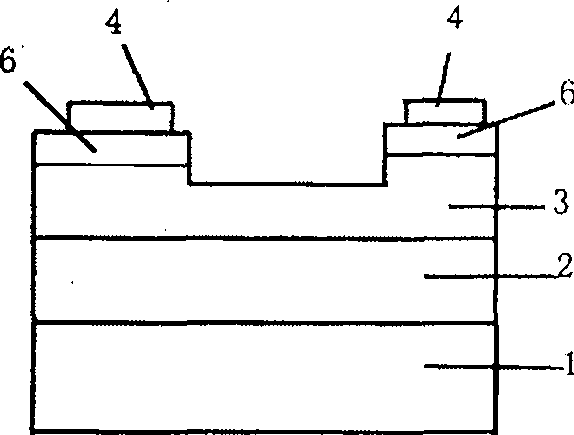

Method of producing p-GaN low-resistance Ohm contact

An ohmic contact and p-gan technology, applied in the field of p-type gallium nitride, can solve the problem of large resistance, reduce contact resistance and improve device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] (1) Using Thomas Swan LP-MOCVD equipment for epitaxial wafer growth, the following three growth schemes are given for sample C.

[0036] 1) The first growth plan

[0037] (a) Load the (0001) orientation no-clean sapphire substrate into the reaction chamber, and 2 Heat to 1080°C and bake for 10 minutes under the atmosphere, and the pressure of the reaction chamber is 500Torr;

[0038] (b) Grow a GaN buffer layer with a thickness of 25nm at 550°C, the growth pressure is 500Torr, the flow rate of TMGa is 40mol / min, NH 3 The flow rate is 110mol / min;

[0039] (c) A 2μm GaN layer was grown at 1060°C, the growth pressure was 200Torr, the TMGa flow rate was 50μmol / min, NH 3 The flow rate is 110mol / min;

[0040] (d) A magnesium-doped GaN layer is grown on the GaN layer at a growth temperature of 800°C, a growth thickness of 500nm, a growth pressure of 200Torr, a TMGa flow rate of 50mol / min, and NH 3 The flow rate is 110mol / min; Cp 2 Mg is 140nmol / min;

[0041] (e) 5 cycle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com