Process system and device for transporting substrates

A process system and substrate technology, applied in the field of process systems, can solve problems such as unstable rotor dynamics, and achieve the effect of flexibility and easy adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

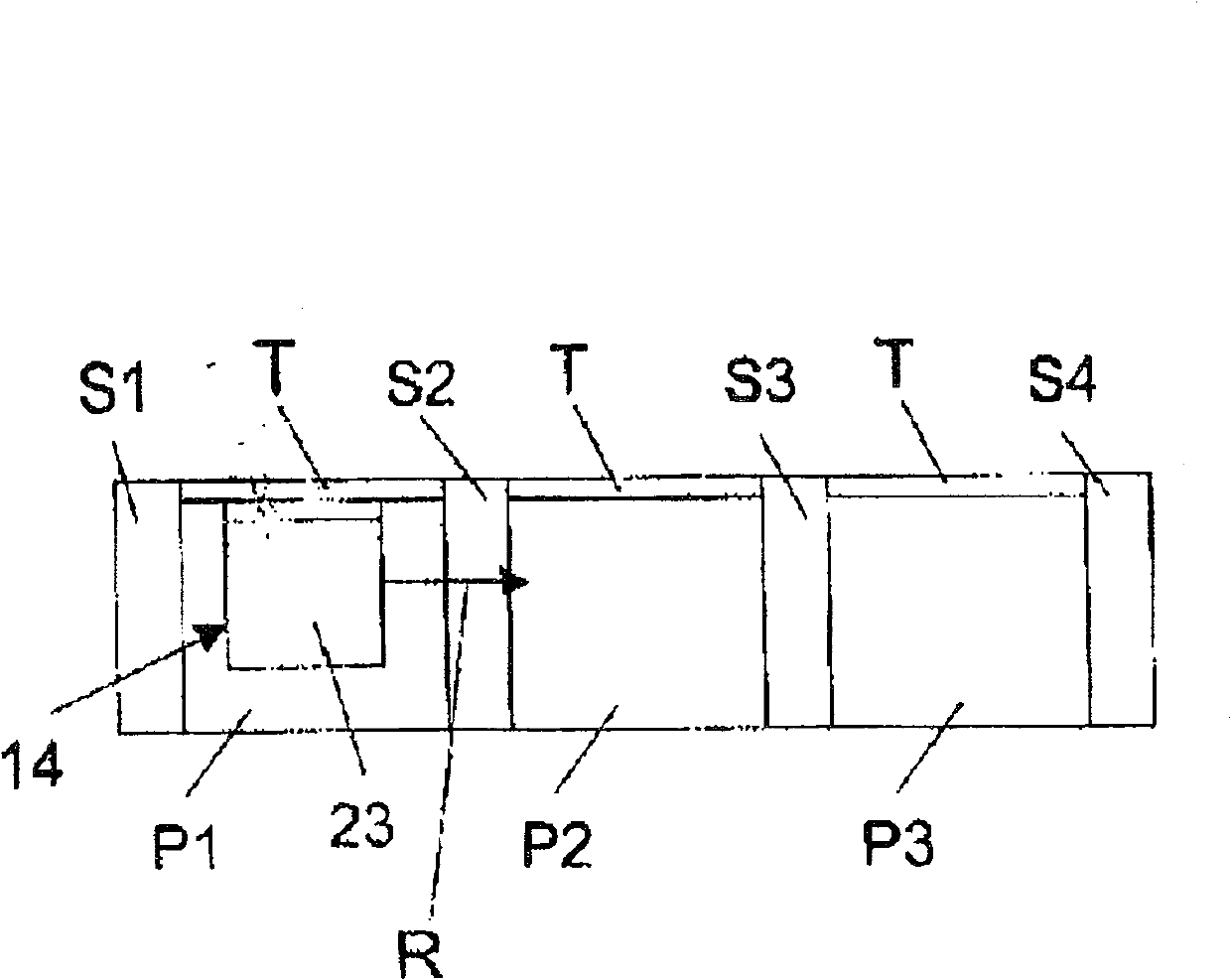

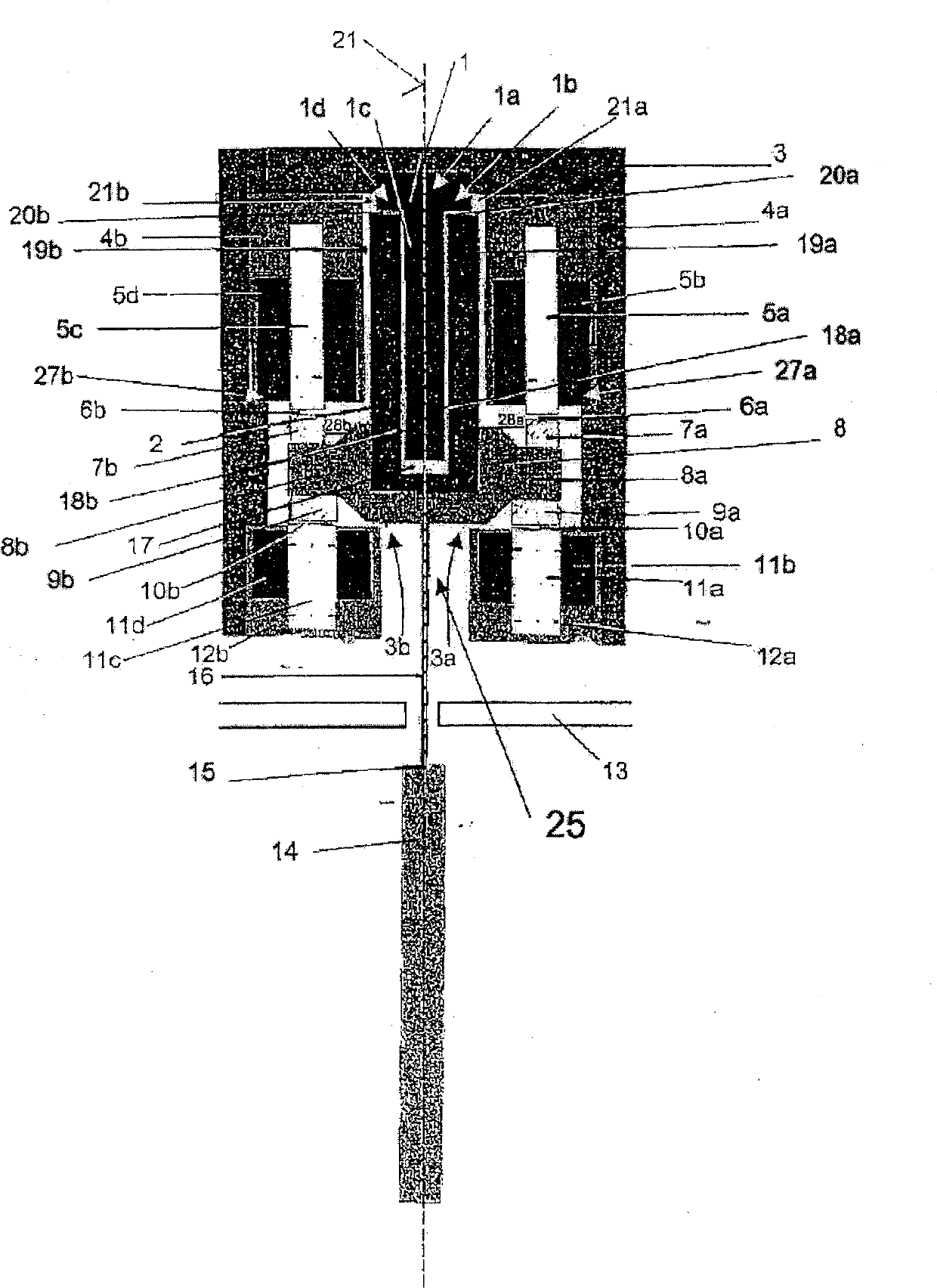

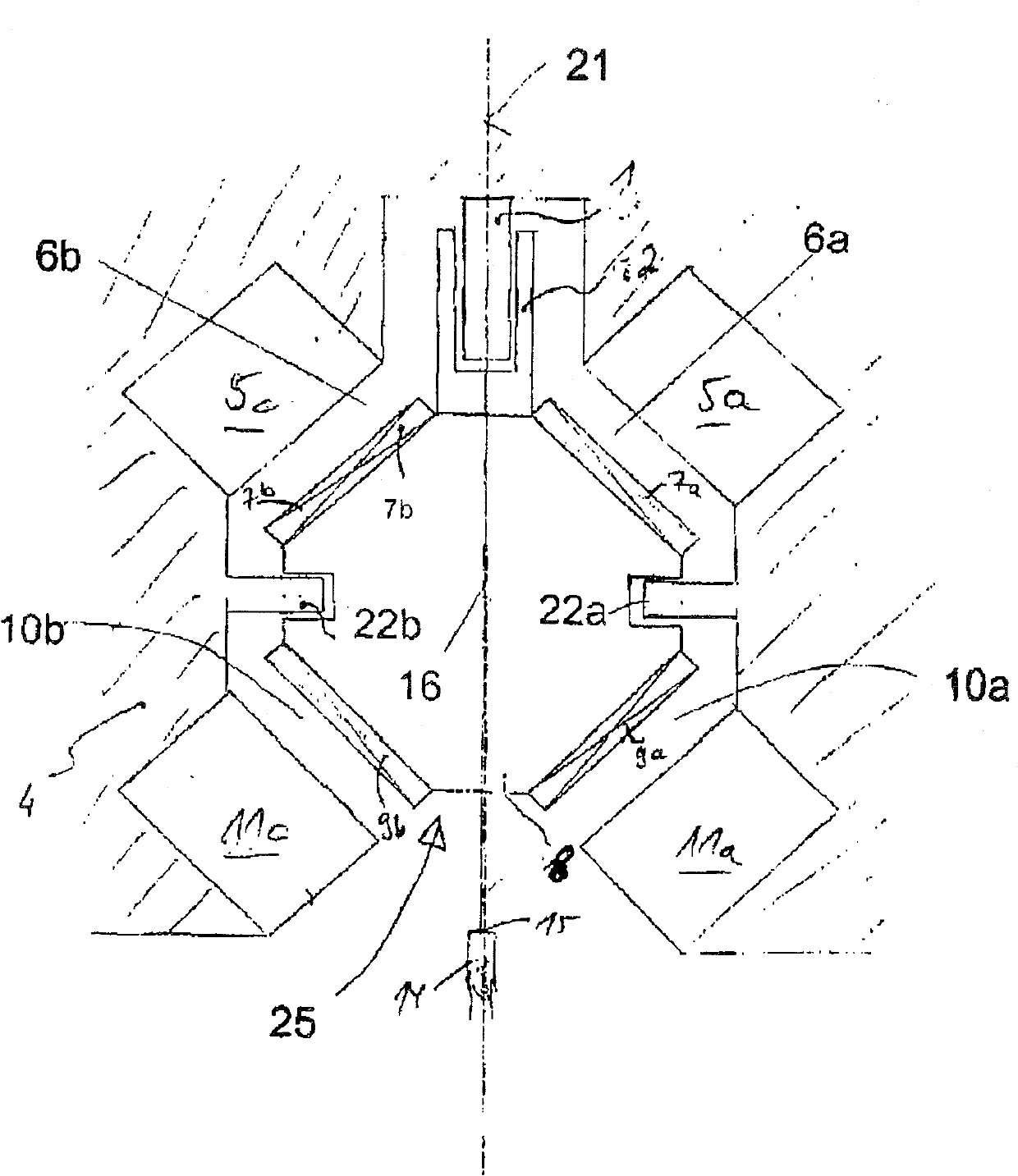

[0027] figure 1 A schematic screenshot of a coating process line with process cavities P1, P2, P3 and gates S1, S2, S3, S4 and a transport line T is shown, where the transport line T is interrupted. The process chambers P1, P2, P3 may be purification chambers, plasma processing chambers, pickling chambers, coating chambers, heating chambers, etc. In the process chamber P1, the substrate 23 is fixed on the device according to the invention by means of a carrier 14, wherein the device includes at least one supporting module with a supporting stator and an active magnetic supporting rotor and a driving module. It goes without saying that the active magnetic support is provided with a distance sensor for the adjustment device, but it is not shown in the figure for the sake of simplifying the view.

[0028] The supporting module has a supporting stator with an exciter configured as an electromagnet and a supporting rotor with a ferromagnetic member. According to the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com