Substrate transfer device and cleaning method thereof and substrate processing system and cleaning method thereof

A substrate processing system and substrate conveying technology, which is applied in the field of substrate processing system and its cleaning, can solve the problems of difficulty in removing particles, lower operating rate of substrate processing system, and inability to transport wafers immediately, and achieve the effect of preventing electrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

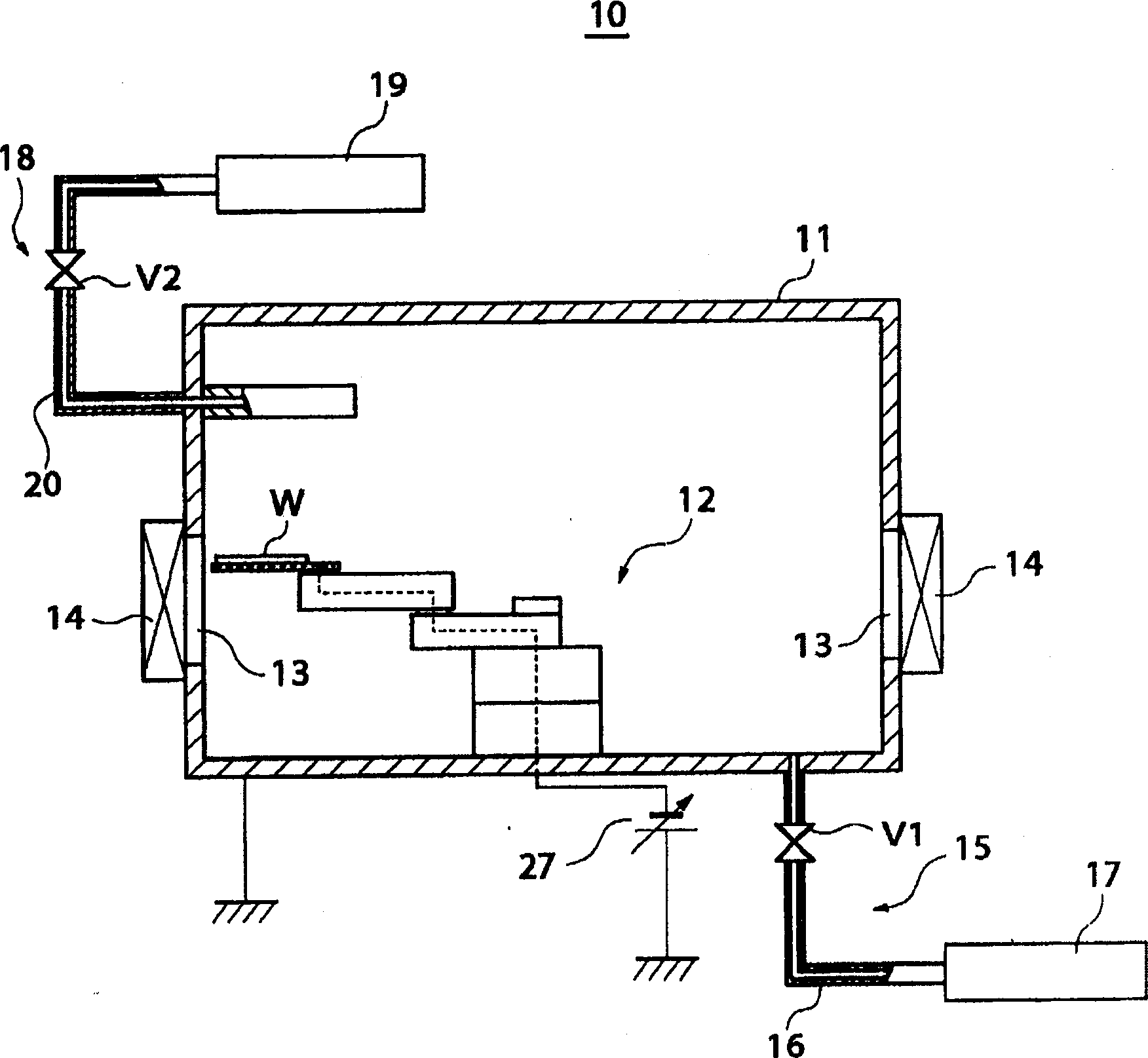

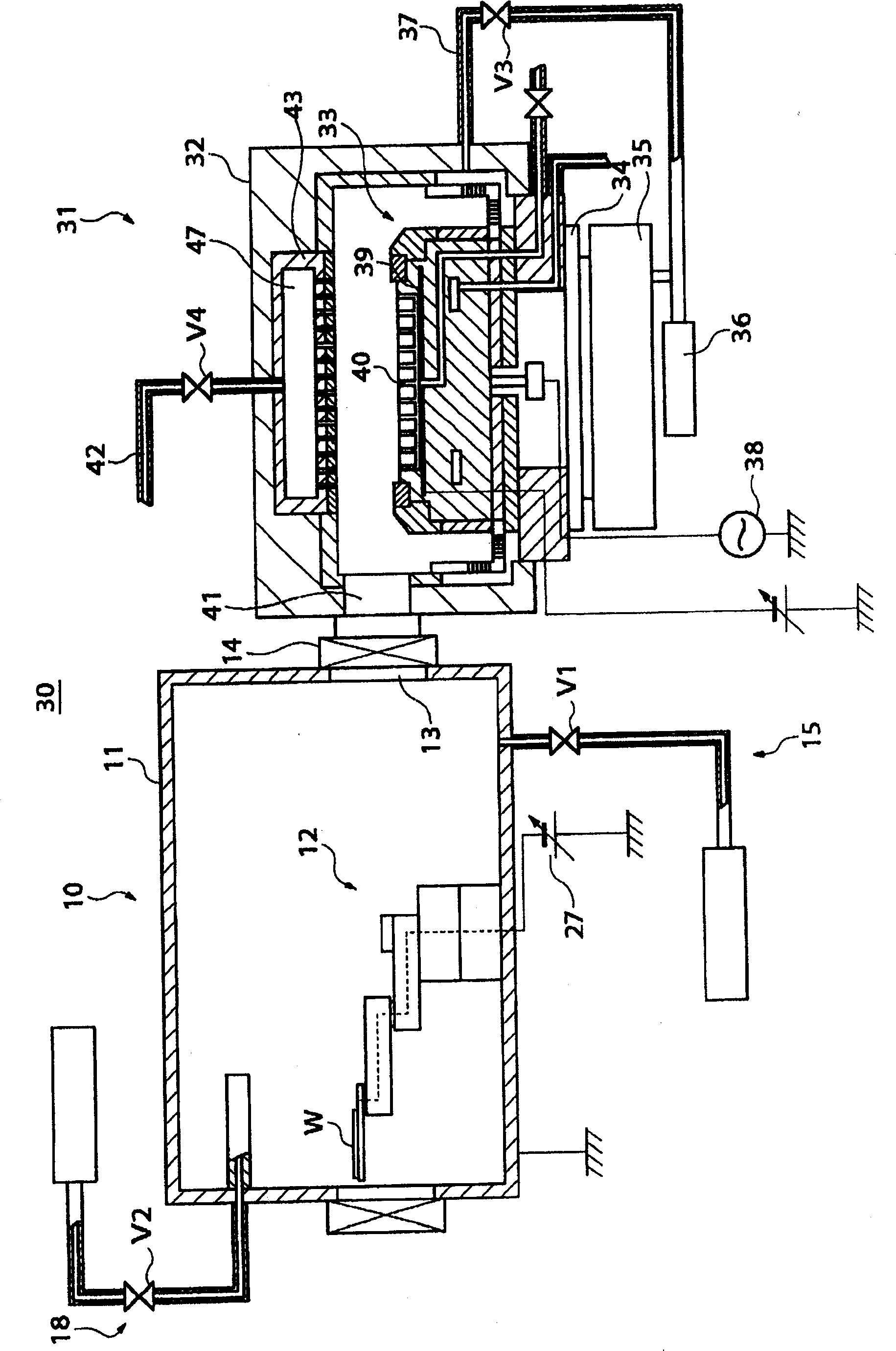

[0087] Embodiments of the present invention will be specifically described below.

[0088] The following embodiments have been implemented in the substrate transfer apparatus 10 described above.

[0089] Figure 4 It is a flow chart showing the evaluation procedure of particle removal processing implemented as an embodiment of the present invention.

[0090] First, the wafer W is carried into the chamber 11 of the substrate transfer device 10, and the initial PWP (Particle per Wafer Pass) is measured by counting the number of particles adhering to the transferred wafer W (step S41). Next, the maintenance window of the substrate transfer device 10 is opened to allow dust in the atmosphere to enter the chamber 11 (step S42). Then, the maintenance window of the substrate transfer device 10 is closed, and the counter of the control device (not shown) of the substrate transfer device 10 is set to "1".

[0091] (Step S43), implement the cleaning method of the above-mentioned subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com