Method for melting high-alumina weakly magnetic metal material by medium frequency induction furnace

A metal raw material and weak magnetic technology, which is applied in the field of melting high-alumina weak magnetic metal raw materials in medium frequency induction furnaces, can solve the problems of shortened furnace lining life, difficult melting, damaged furnace lining, etc., and achieves improved furnace lining life, low cost, and less investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The nominal capacity of the intermediate frequency induction furnace of this embodiment is 8 tons.

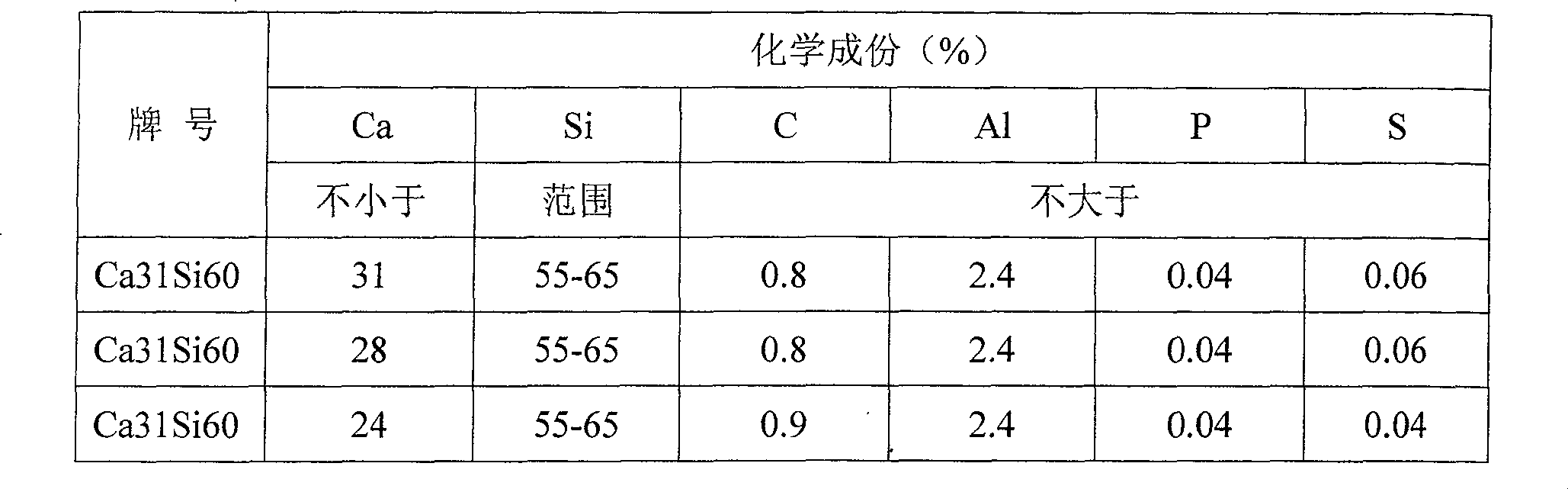

[0046] Add 7.2 tons of non-magnetic high-manganese-aluminum 20Mn23AlV mixed steel scrap raw materials into an intermediate frequency induction furnace and send electricity for melting. When the metal materials in the intermediate frequency induction furnace are all melted, the temperature is measured to reach 1533℃, and then added to the upper part of the molten metal Silicon-calcium alloy (Ca31Si60) 3.4kg, after the silicon-calcium alloy is added, a strong oxidation reaction occurs on the upper part of the metal liquid instantaneously. After the silicon-calcium alloy is added for 22 minutes, non-magnetic 20Mn23AlV molten steel is released.

[0047] In this embodiment, after tapping, no slag sticking phenomenon was found in the molten metal surface of the furnace lining, and the original shape of the furnace lining was maintained.

Embodiment 2

[0049] The nominal capacity of the intermediate frequency induction furnace of this embodiment is 8 tons.

[0050] Add 8 tons of non-magnetic high-manganese aluminum 45Mn17Al13 mixed scrap raw materials into the intermediate frequency induction furnace to send electricity for melting. When the raw materials in the intermediate frequency induction furnace are all melted, the temperature is measured to 1530℃, and then silicon is added to the upper part of the molten metal. Calcium alloy (Ca31Si60) 4.3kg. After silicon calcium alloy is added, a strong oxidation reaction occurs on the upper part of the metal liquid instantaneously. After adding calcium silicon alloy (Ca31Si60) for 20 minutes, non-magnetic 45Mn17Al13 molten steel is released.

[0051] In this embodiment, after tapping, no slag sticking phenomenon was found at the molten metal surface of the furnace lining, and the furnace lining was kept in its original shape.

Embodiment 3

[0053] The nominal capacity of the intermediate frequency induction furnace of this embodiment is 8 tons.

[0054] Add 6 tons of manganese-aluminum alloy (FeAl22Mn32) into the intermediate frequency induction furnace and send electricity to melt. When the metal raw materials in the intermediate frequency induction furnace are all melted, the measured temperature reaches 1540℃, and then the silicon-calcium alloy is added to the upper part of the molten metal. (Ca31Si60) 6.2kg, after the silicon-calcium alloy is added, a strong oxidation reaction occurs on the upper part of the metal liquid instantaneously. After the silicon-calcium alloy is added for 28 minutes, the manganese aluminum alloy molten steel is released.

[0055] Due to operational errors, in this embodiment, after the steel is tapped, basically no slag sticking phenomenon is found at the molten metal surface of the furnace lining. The slag sticking phenomenon is much less than before using this method, and the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com