Slag-splashing converter protection gun position control method for steelmaking converter

A technology for protecting furnace with slag splashing and steelmaking converter, applied in the field of metallurgy, can solve problems such as unfavorable slag splashing protecting furnace, and achieve the effects of maintaining production, prolonging the life of furnace lining and uniform erosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment.

[0022] The method for controlling the position of the slag-splashing protection gun of the steelmaking converter of the present invention comprises the following steps:

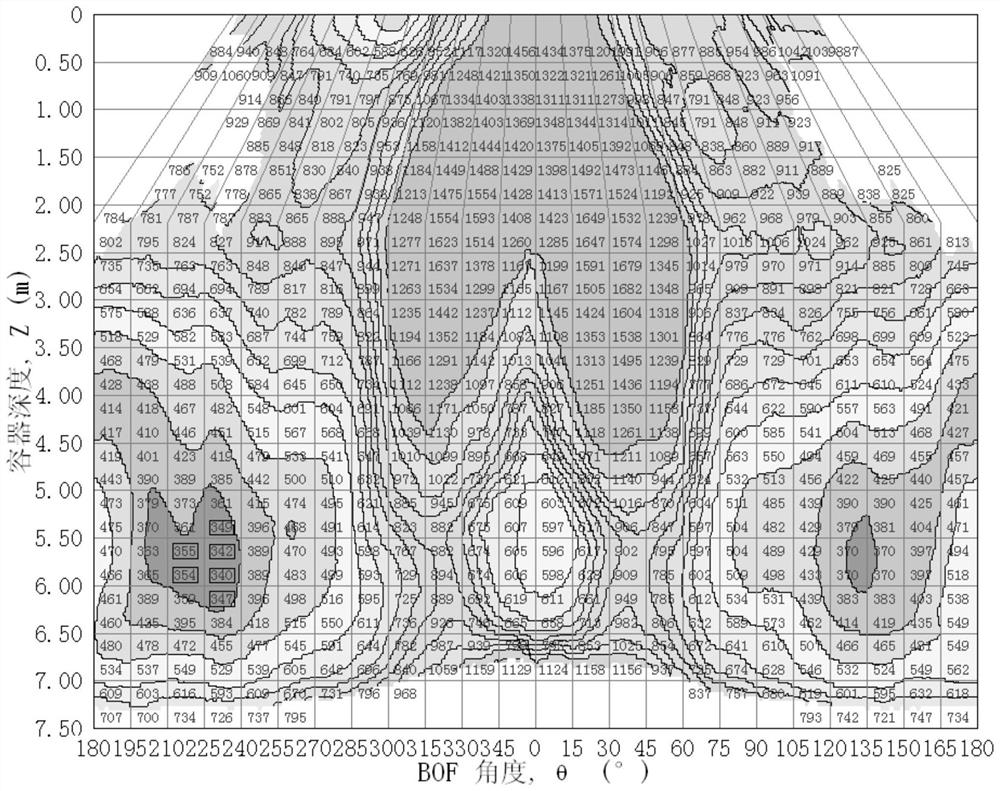

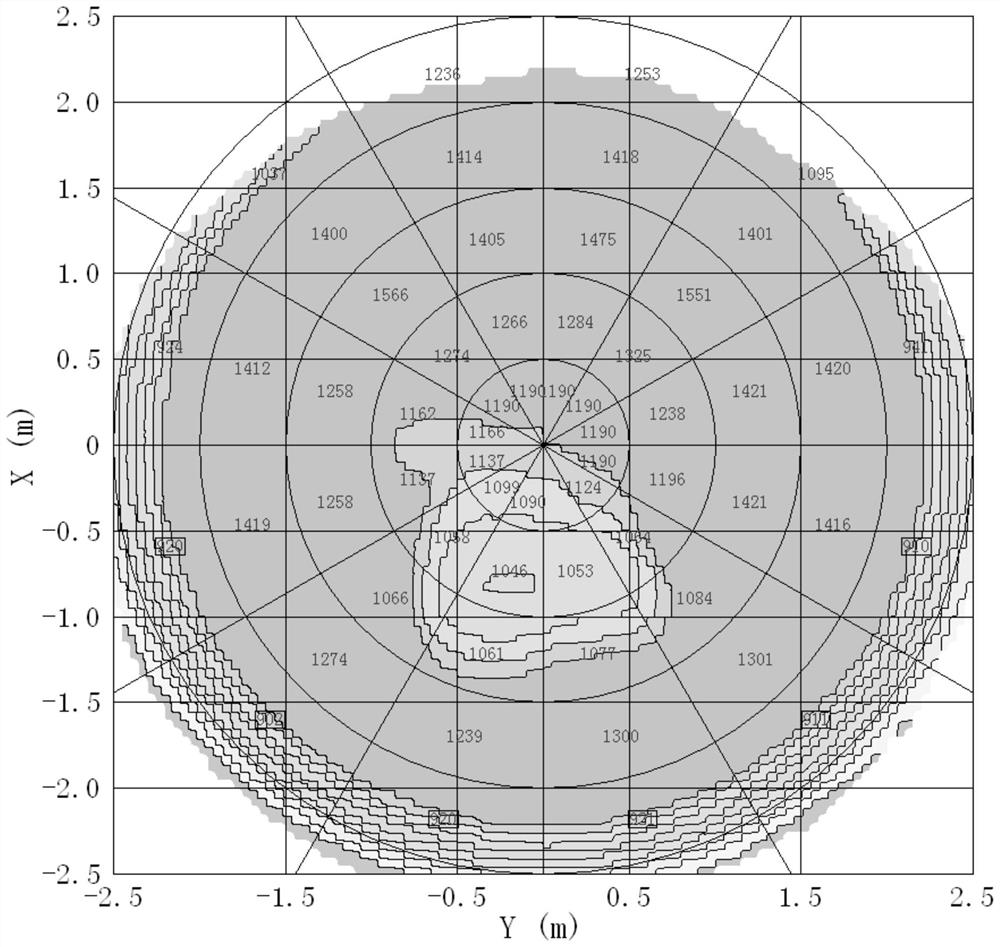

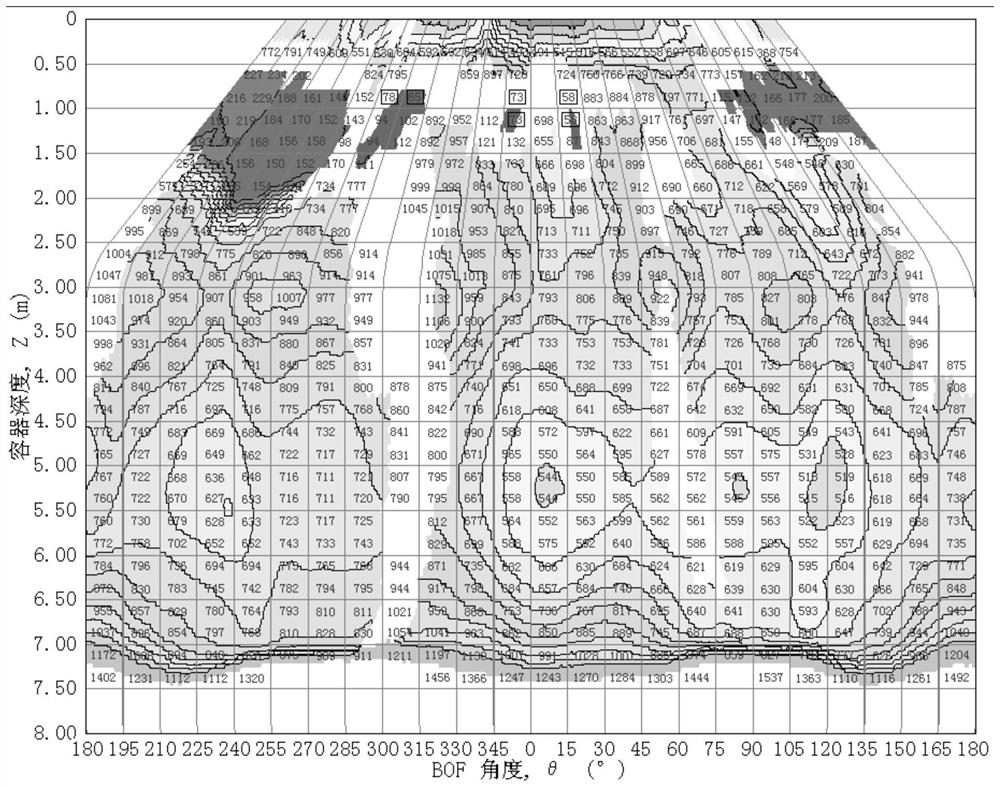

[0023] S1. Measure the erosion of each part of the furnace lining, obtain the position of the weak area of the furnace lining, and determine the height of the area that needs slag splashing, that is, determine the slag splashing height H 高 , slag splash height H 高 including cap H 高上 and lower limit H 高下 . This step can be carried out at the end of tapping or when the furnace is shut down and waiting. Since the height of the slag splashing area is a range, the height of the slag splashing is also a range, and the range is recorded as the upper limit H 高上 and lower limit H 高下 .

[0024] For example, taking Panzhihua Iron and Steel No. 3 converter (furnace age 10240) as an example, the thickness of the convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com