Nano cuprous oxide and nano silver compounded sea anti-fouling paint

A nano-cuprous oxide, marine antifouling technology, applied in the field of coatings, can solve problems such as damage, water resistance, flexibility reduction, etc., and achieve the effects of reasonable and stable control, good matching, and uniform erosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

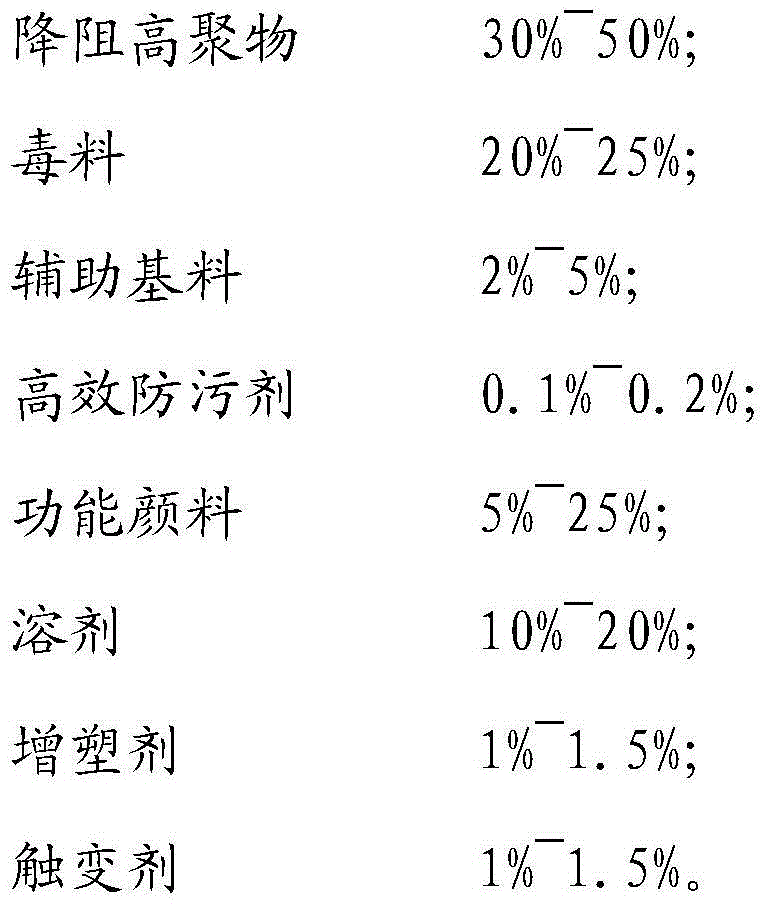

Method used

Image

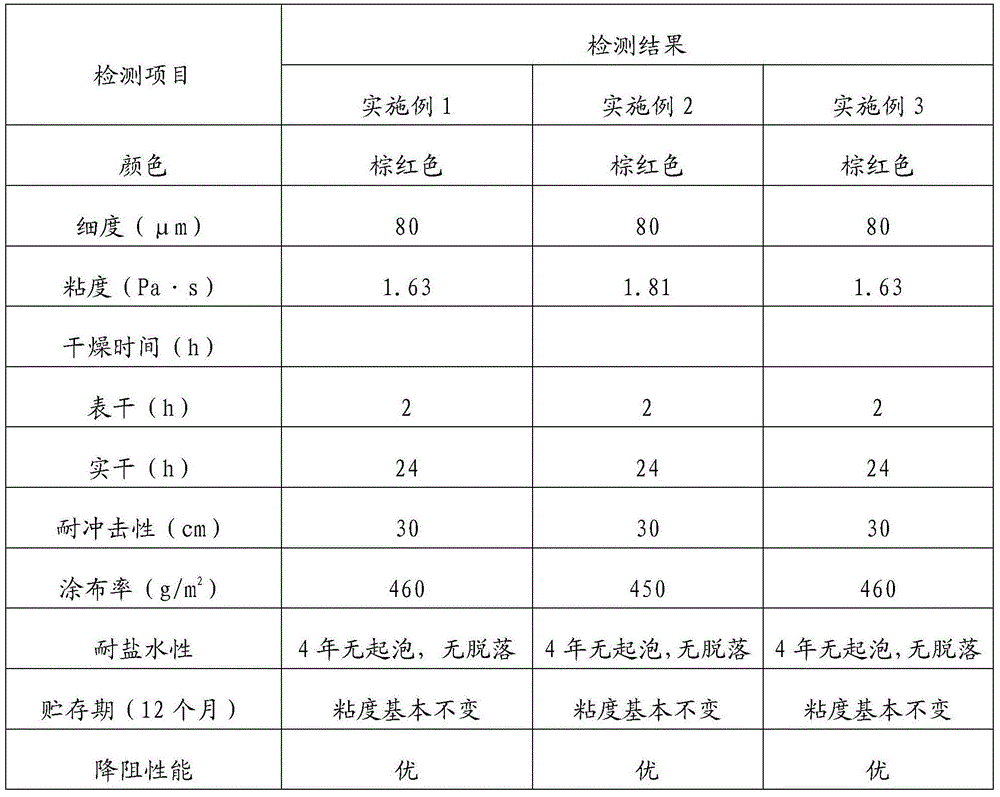

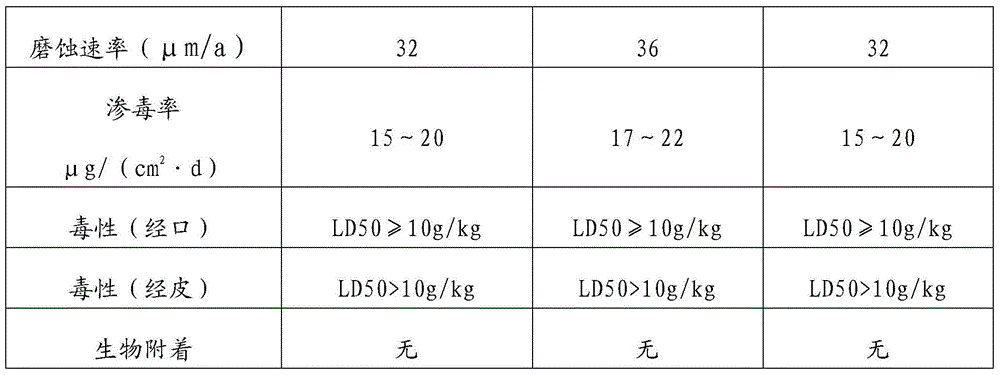

Examples

Embodiment 1

[0026] A marine antifouling paint made of nano cuprous oxide and nano silver. Its formula and mass percentage are: acrylic resin 40%, chlorinated rubber 4%, nano cuprous oxide 20%, nano silver sol 0.1%, talc powder 5% , Zinc oxide 8%, iron red 10%, wax slurry 1%, bentonite 1%, natural capsaicin 1%, mixed solvent 13%.

Embodiment 2

[0028] A marine antifouling paint made of nano cuprous oxide and nano silver. Its formula and mass percentage are: acrylic resin 40%, chlorinated rubber 4%, nano cuprous oxide 25%, nano silver sol 0.2%, talc 5% , Zinc oxide 8%, iron red 10%, wax paste 1%, bentonite 1%, mixed solvent 13%.

Embodiment 3

[0030] A marine antifouling coating of nano cuprous oxide and nano silver, its formula and mass percentage are: acrylic resin 40%, chlorinated rubber 4%, nano cuprous oxide 20%, nano silver sol 0.2%, talc powder 5% , Zinc oxide 8%, iron red 10%, wax slurry 1%, bentonite 1%, mixed solvent 13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com