Preformed piece for plate blank tundish and preparation method thereof

A technology of prefabricated parts and tundish, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of refractory materials and slag falling off, achieve good thermal shock resistance, improve lining life, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

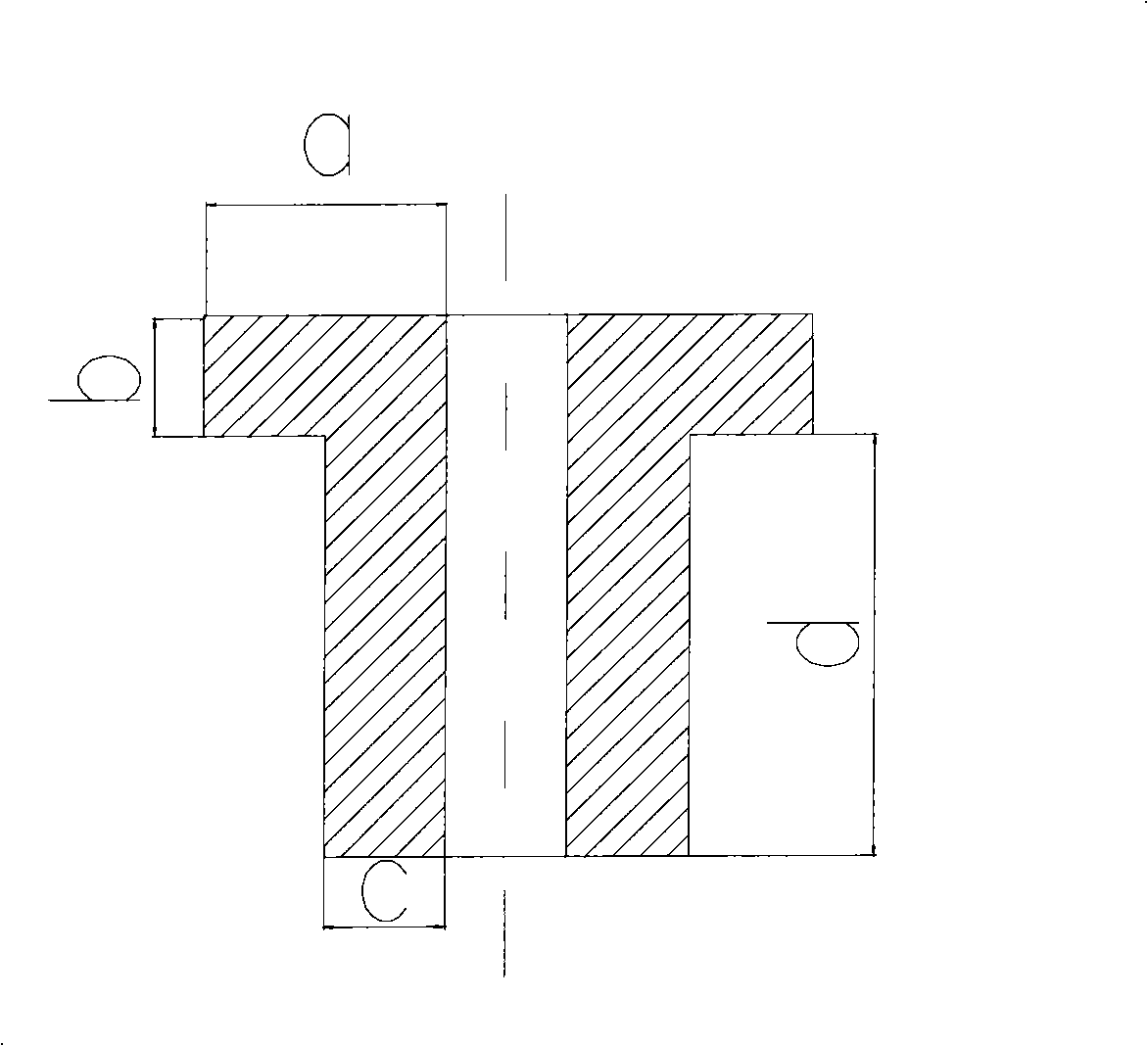

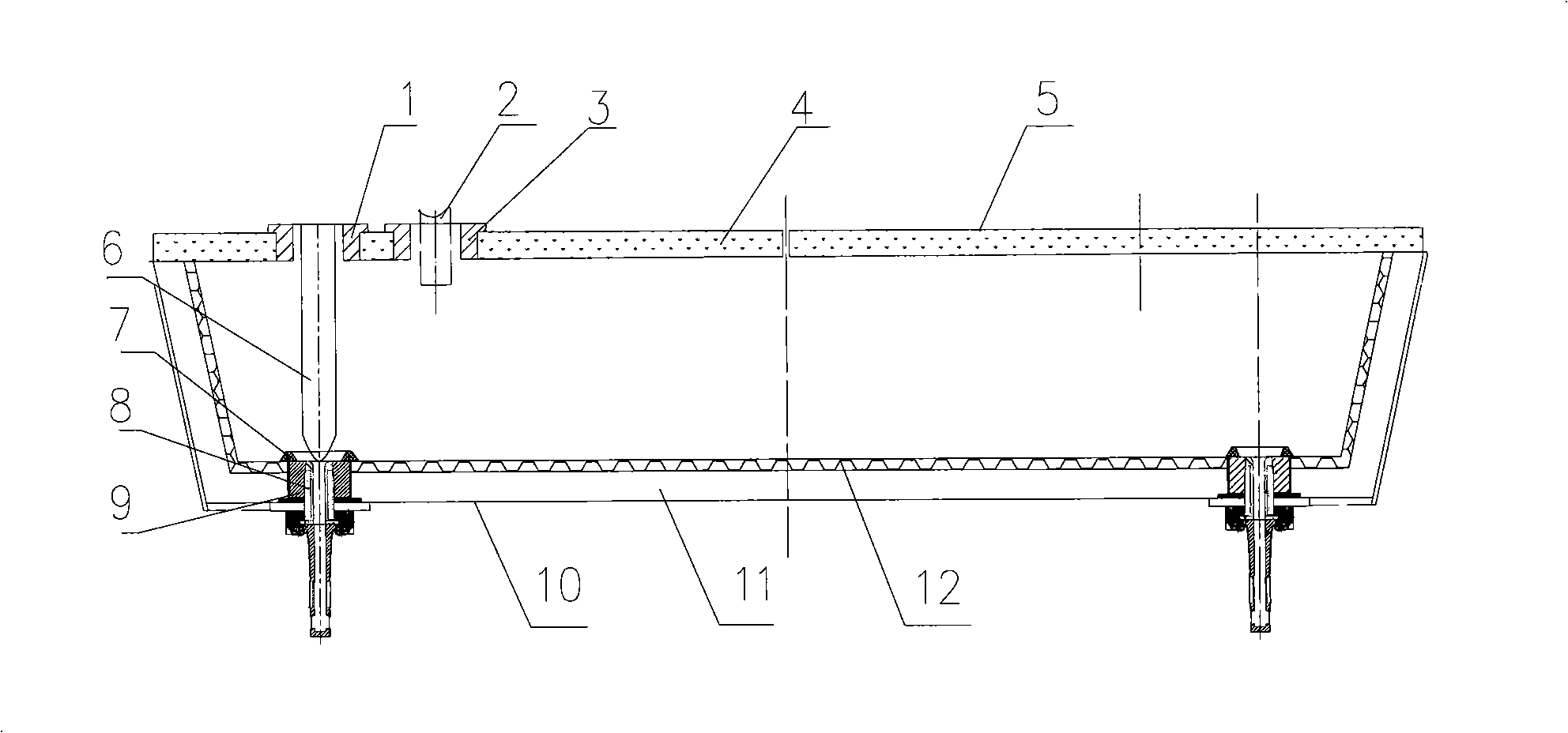

Method used

Image

Examples

Embodiment 1

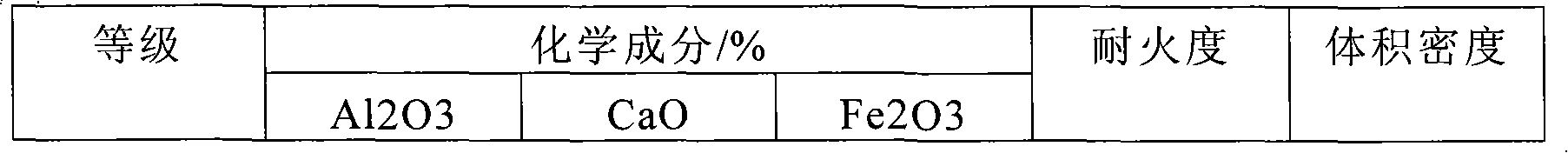

[0056] A prefabricated part for a slab tundish consisting, in percentage by weight, of the following materials:

[0057] 30% of the first-grade high-bauxite with a particle size of 10-5mm, 12% of the first-grade high-bauxite with a particle size of 2 1.0% of superfine powder, 3.5% of calcium aluminate cement, both are percentages by weight.

[0058] The high-alumina bauxite is first-grade high-alumina bauxite, and the sintered magnesia is sintered magnesia with a MgO content percentage of 95%. The SiO 2 Ultrafine powder is: SiO 2 The content is ≥92%, and the particle size is less than 2 μm, which accounts for 80-85%, and all of them are less than 5 μm.

[0059] After weighing the above-mentioned materials according to the stated ratio, add them into the mixer for dry mixing for 2-3 minutes, add 6-8% water of the total weight of the materials, and wet-mix for 4-6 minutes, put the mixed castable Put the material into the tire mold, distribute the material evenly, vibrate and ...

Embodiment 2

[0066] A prefabricated part for a slab tundish consisting, in percentage by weight, of the following materials:

[0067] 35% of the first-grade high-bauxite with a particle size of 10-5mm, 10% of the first-grade high-bauxite with a particle size of 2 1.2% of superfine powder, 3.5% of calcium aluminate cement, both are percentages by weight.

[0068] The high-alumina bauxite is first-grade high-alumina bauxite, and the sintered magnesia is sintered magnesia with a MgO content percentage of 95%. The SiO 2 Ultrafine powder is: SiO 2 The content is ≥92%, and the particle size is less than 2 μm, which accounts for 80-85%, and all of them are less than 5 μm.

[0069] After weighing the above-mentioned materials according to the stated ratio, add them into the mixer for dry mixing for 2-3 minutes, add 6-8% water of the total weight of the materials, and wet-mix for 4-6 minutes, put the mixed castable Put the material into the tire mold, distribute the material evenly, vibrate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com