Dolomite non-burning carbon brick and preparation method thereof

A technology of dolomite and carbon bricks is applied in the field of new dolomite non-burning carbon bricks and their preparation, which can solve the problem that the hydration resistance needs to be improved, so as to improve the hydration resistance, improve the life of the furnace lining and prevent water the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

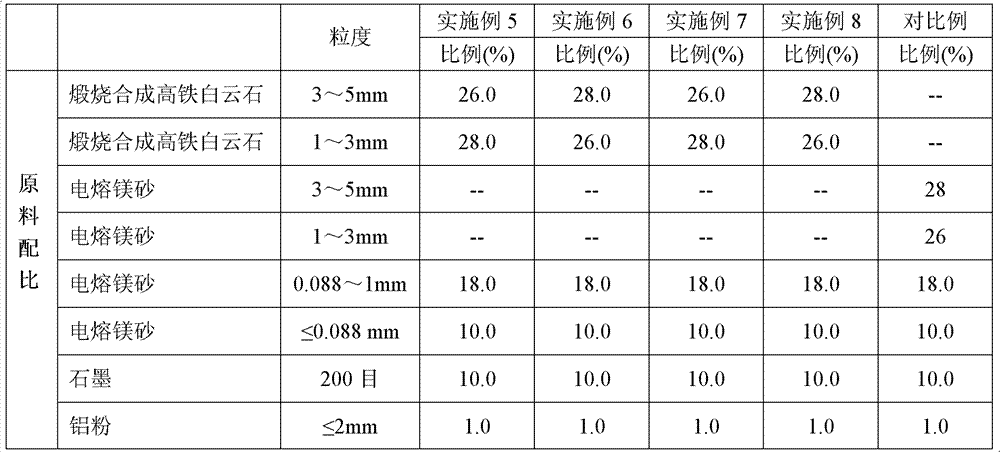

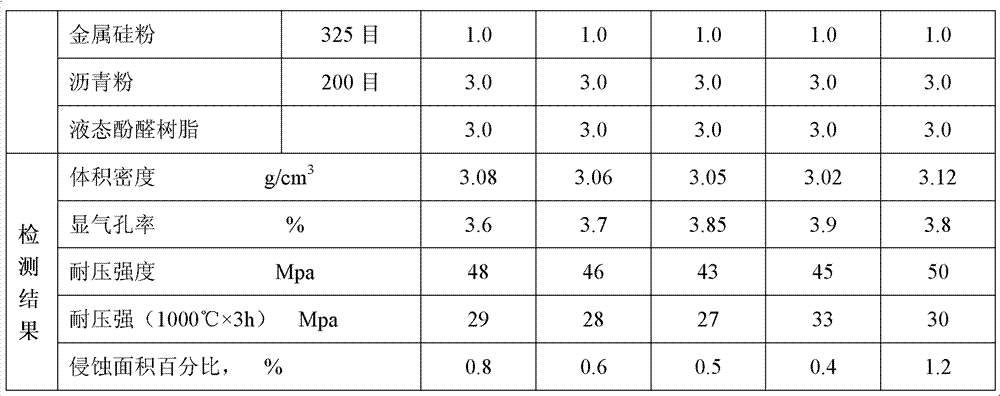

[0026] A dolomite non-fired carbon brick, which uses calcined synthetic high-iron dolomite that is not broken after leaving the kiln as aggregate, and in the calcined synthetic high-iron dolomite, Fe 2 o 3 5-10% by weight, and 20-40% by weight of CaO; the dolomite non-fired carbon brick is made of the following raw materials in proportion by weight:

[0027] Calcination to synthesize high-iron dolomite 3mm~5mm 26

[0028] Calcination to synthesize high-iron dolomite 1mm~3mm 28

[0029] Fused magnesia 0.088mm~1mm 20

[0030] Fused magnesia ≤0.088mm 10

[0031] Graphite 8

[0032] Aluminum powder 2

[0033] Silica fume 2

[0034] asphalt 2

[0035] Phenolic resin 2.

[0036] The method of calcining and synthesizing high-iron dolomite is as follows: use natural dolomite ore, lightly burn at 900°C-1200°C to obtain lightly burnt dolomite, add iron oxide red to the digested dolomite, oxidize The amount of iron red added is 5-10% of the total weight; then artificial granulat...

Embodiment 2

[0042]A dolomite non-fired carbon brick, which uses calcined synthetic high-iron dolomite that is not broken after leaving the kiln as aggregate, and in the calcined synthetic high-iron dolomite, Fe 2 o 3 5-10% by weight, and 20-40% by weight of CaO; the dolomite non-fired carbon brick is made of the following raw materials in proportion by weight:

[0043] Calcined synthetic high-iron dolomite 3mm~5mm 28

[0044] Calcination to synthesize high-iron dolomite 1mm~3mm 25

[0045] Fused magnesia 0.088mm~1mm 18

[0046] Fused magnesia ≤0.088mm 12

[0047] Graphite 11

[0048] Aluminum powder 1

[0049] Silica fume 1

[0050] asphalt 2

[0051] Phenolic resin 2.

[0052] The method for calcining and synthesizing high-iron dolomite is as follows: use natural dolomite ore, lightly burn at a temperature of 900°C-1200°C to obtain lightly burnt dolomite, and add dolomite with a particle size of ≤0.088mm to the digested dolomite. The magnesia fine powder is mixed evenly, and the...

Embodiment 3

[0055] A dolomite non-fired carbon brick, which uses calcined synthetic high-iron dolomite that is not broken after leaving the kiln as aggregate, and in the calcined synthetic high-iron dolomite, Fe 2 o 3 5-10% by weight, and 30-55% by weight of CaO; the dolomite non-fired carbon brick is made of the following raw materials in proportion by weight:

[0056] Calcined synthetic high-iron dolomite 3mm~5mm 30

[0057] Calcination to synthesize high-iron dolomite 1mm~3mm 26

[0058] Fused magnesia 0.088mm~1mm 22

[0059] Fused magnesia ≤0.088mm 15

[0060] graphite 5

[0061] Aluminum powder 4

[0062] Silicon fume 3

[0063] asphalt 5

[0064] Phenolic resin 4.

[0065] The method for calcining and synthesizing high-iron dolomite is as follows: use natural dolomite ore, lightly burn at a temperature of 900°C-1200°C to obtain lightly burnt dolomite, and add dolomite with a particle size of ≤0.088mm to the digested dolomite. The magnesia fine powder is mixed evenly, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com