Phase storage element and manuafcturing method thereof

A storage element and manufacturing method technology, applied in the direction of electrical components, etc., can solve the problems of reaction, metal polymer diffusion, expansion, etc., achieve the best thermal limit capability, easy component simulation and theoretical calculation, fast component simulation and theoretical calculation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

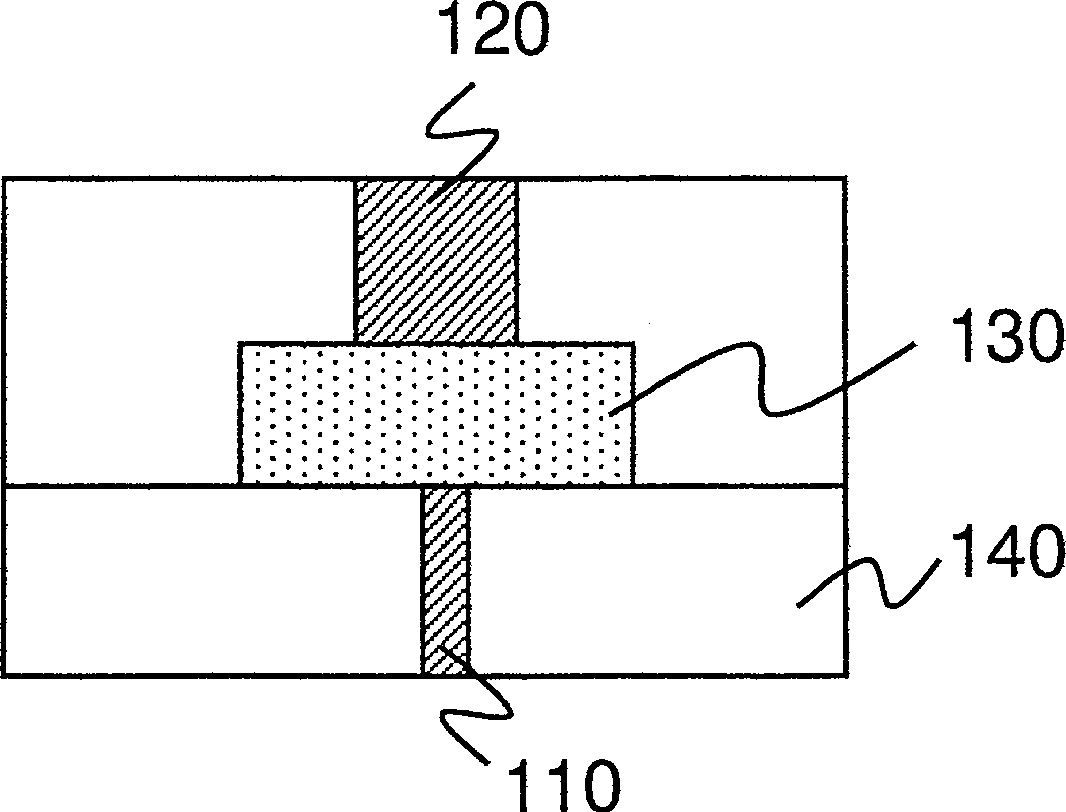

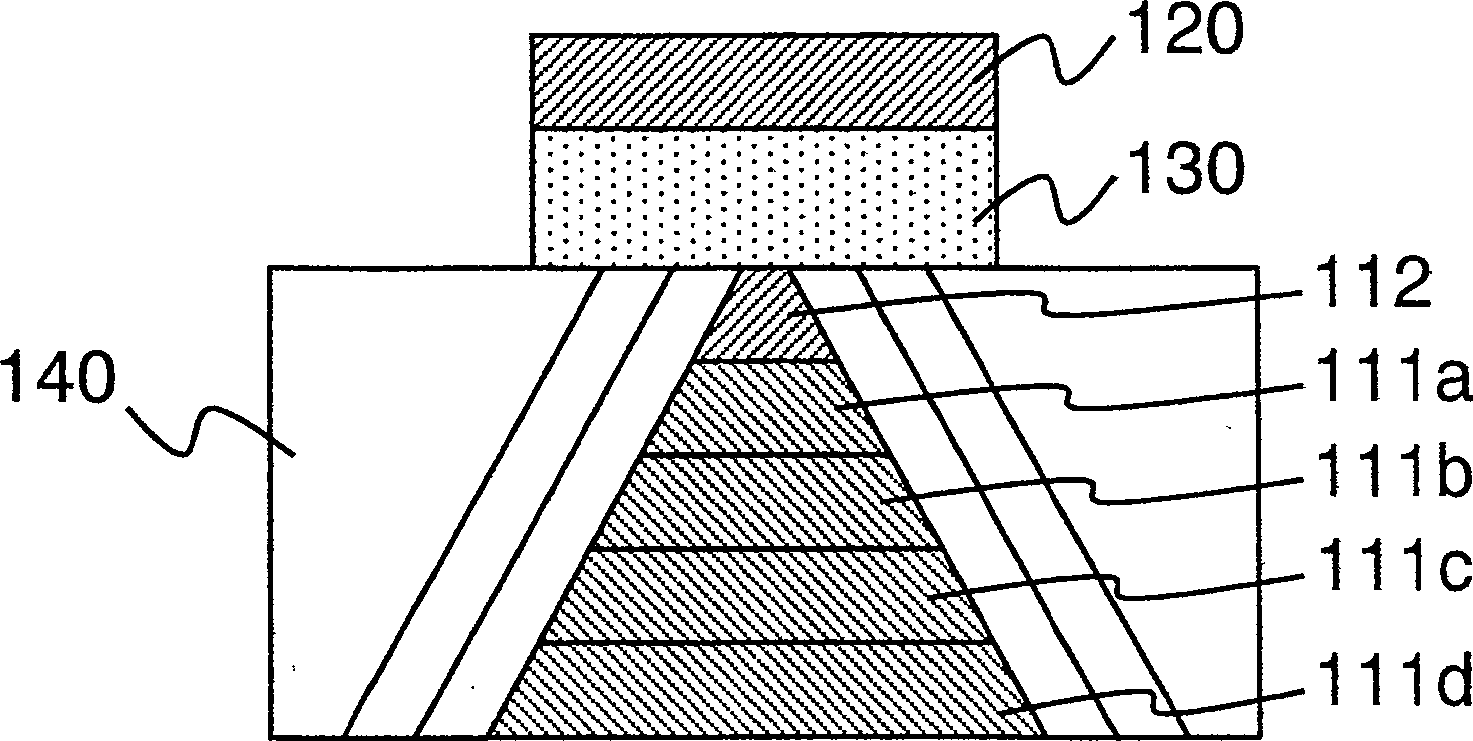

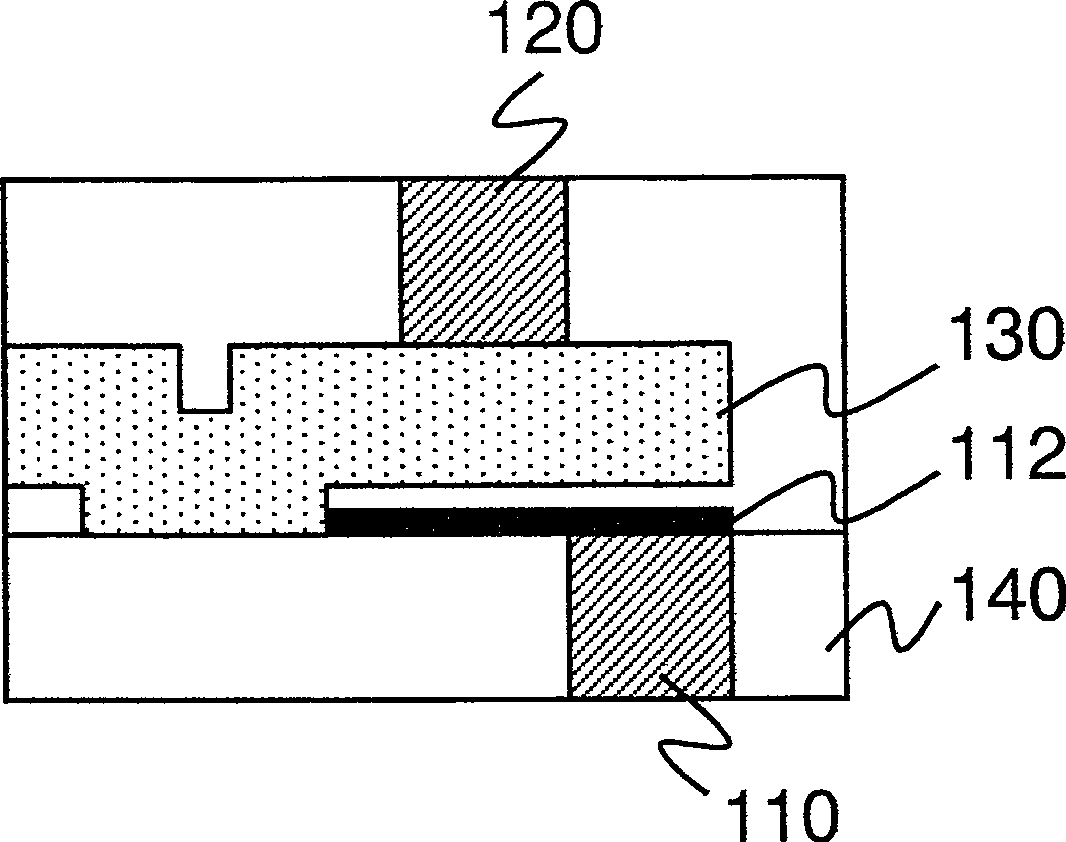

[0075] Please refer to Figure 5A with Figure 5B , is a phase-change memory element according to an embodiment of the present invention. This phase change memory element is in the shape of a two-dimensional disk, which has a first electrode 210, a first insulating layer 240, a phase change layer 230, a second insulating layer 242, a central through hole 250, a heating electrode 212, and a third insulating layer 244. , the annular through hole 252 and the second electrode 220 . Here, the first electrode 210 , the first insulating layer 240 , the phase change layer 230 and the second insulating layer 242 are sequentially stacked from bottom to top, and the phase change layer 230 and the second insulating layer 242 present a disc shape. The central through hole 250 is roughly located at the center of the disc shape, passing through the first insulating layer 240, the phase change layer 230 and the second insulating layer 242 until the interface of the first electrode 210; and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com