Fast shaping nylon 66 resin and its preparation method

A nylon and resin technology, which is applied in the field of rapid prototyping nylon 66 resin and its preparation, can solve problems such as not involving rapid prototyping, and achieve the effects of improved physical properties, easy implementation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The nylon 66 powder was vacuum-dried at 90° C. for 24 hours to obtain a dry nylon 66 resin.

[0017] Select the mixture of polyamide 46, polyamide 22, polyamide 22 and sodium phenyl hypophosphite, magnesium oxide, talcum powder, calcium fluoride as nucleating agent, according to the weight ratio of 99 parts of nylon 66 and 1 part of nucleating agent, They were mixed with nylon 66 on a high-speed kneader for 5 minutes, dried in vacuum at 90°C for 24 hours, extruded and granulated by a twin-screw extruder, and injection molded into standard test strips.

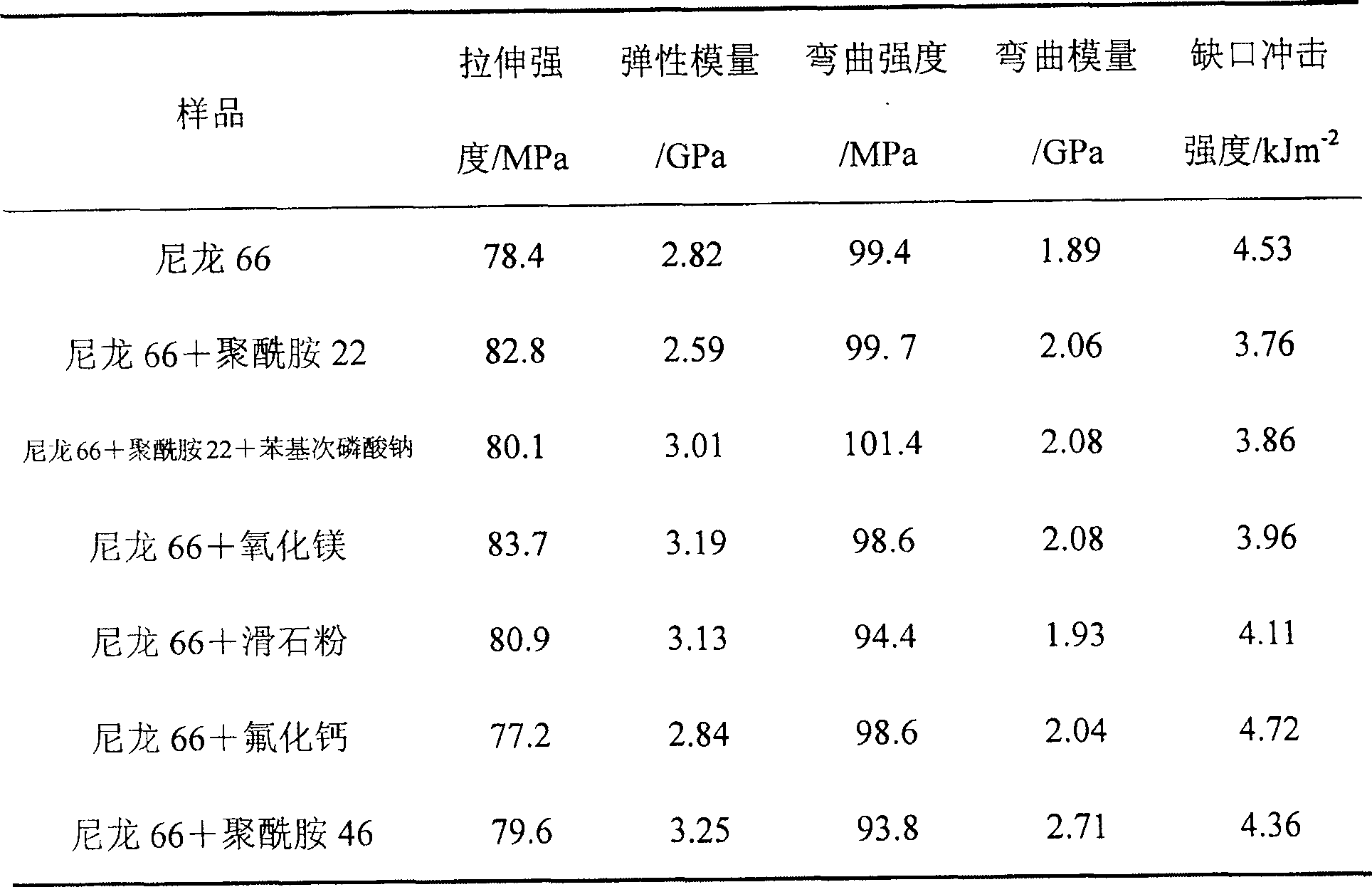

[0018] The tensile, bending and impact properties of various rapid prototyping nylon 66 were tested, and the results are listed in Table 1. The standards for this table are tensile GB / T1042-92, bending GB / T9341-88 and impact GB / T1843-1996.

[0019] Table 1 Mechanical properties of nylon 66 with different nucleating agents

[0020]

Embodiment 2

[0022] Add nylon 66 monomer to the polymerization kettle, add 800ppm of nucleating agent of mixture of sodium tert-butyl hypophosphite and polyamide 22 during the polymerization process of nylon 66, and make it disperse evenly under the action of polymerization heat and stirring, after the polymerization is completed Discharging, pelletizing, and then vacuum drying at 80-110°C for 18-24 hours or under N 2 Under protection, dry at 80-110°C for 18-24 hours to obtain the product.

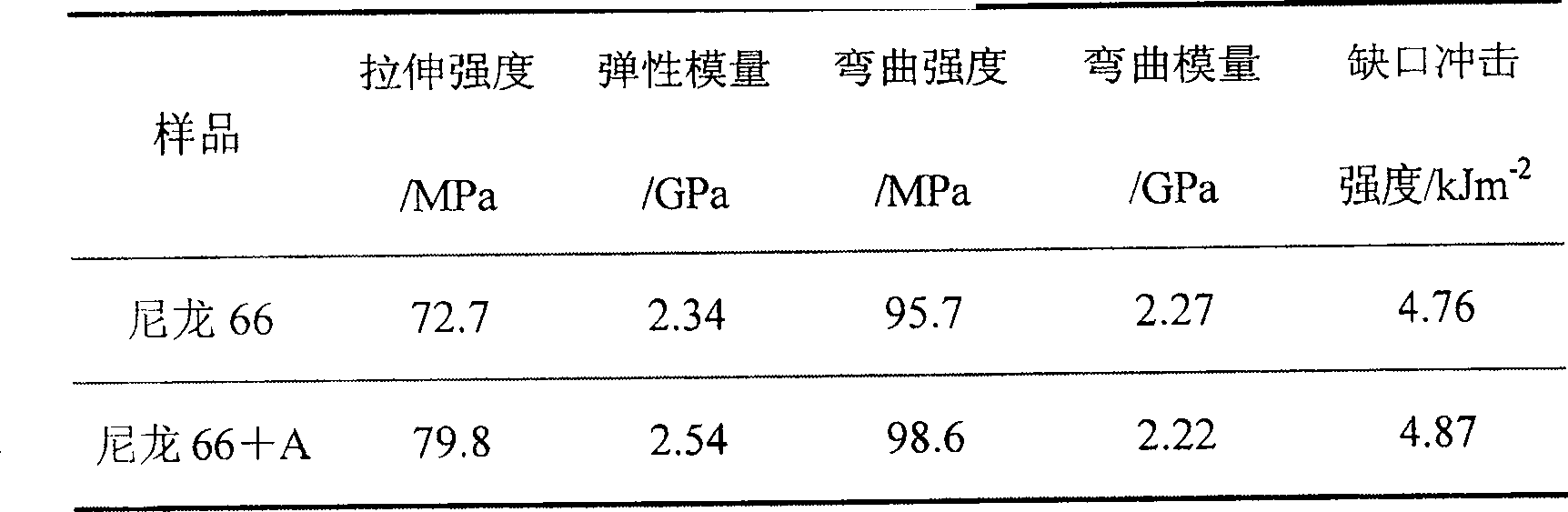

[0023] The tensile, bending and impact properties of the rapid prototyping nylon 66 prepared by the above method were tested, and the results obtained are listed in Table 2. This table is based on the same standard as Table 1.

[0024] Table 2 Mechanical properties of nylon 66 with nucleating agent added during polymerization

[0025]

[0026] In Table 2, A represents the mixture of sodium tert-butyl hypophosphite and polyamide 22

Embodiment 3

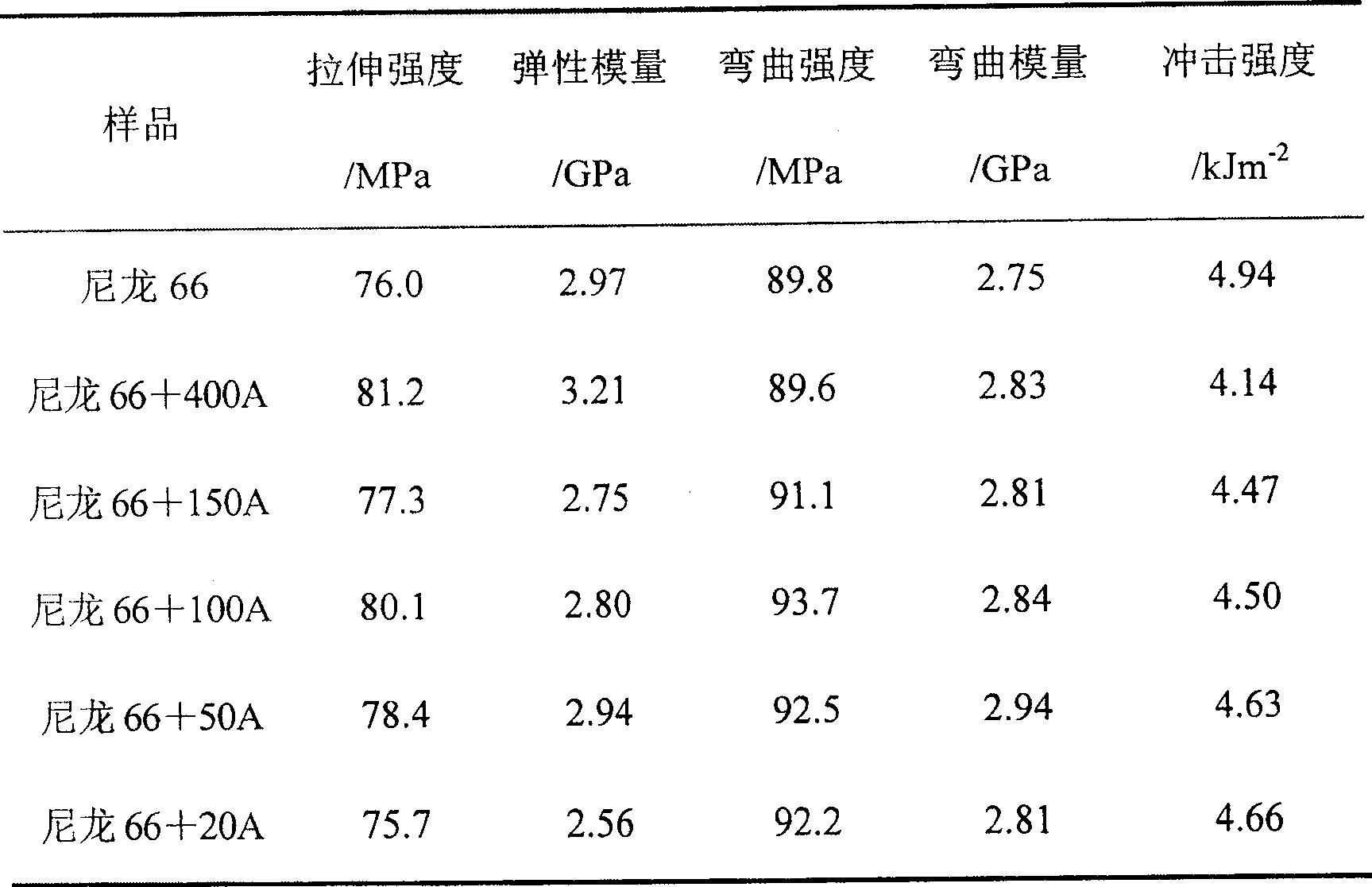

[0028] Add different contents of nucleating agent A (same as Example 2) in the polymerization process of nylon 66, its contents are respectively 400ppm, 150ppm, 100ppm, 50ppm and 20ppm, and the contents are respectively recorded as 400A, 150A, 100A, 50A and 10A. Vacuum dried at 90°C for 24 hours, and formed into standard test strips.

[0029] The mechanical properties of rapid prototyping nylon 66 with different nucleating agent contents were tested, and the results are listed in Table 3, which is based on the same standards as Table 1.

[0030] Table 3 Mechanical properties of samples with different nucleating agent content

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com