Cooling packaging method for vehicle-mounted liquid cooling power electronic controller

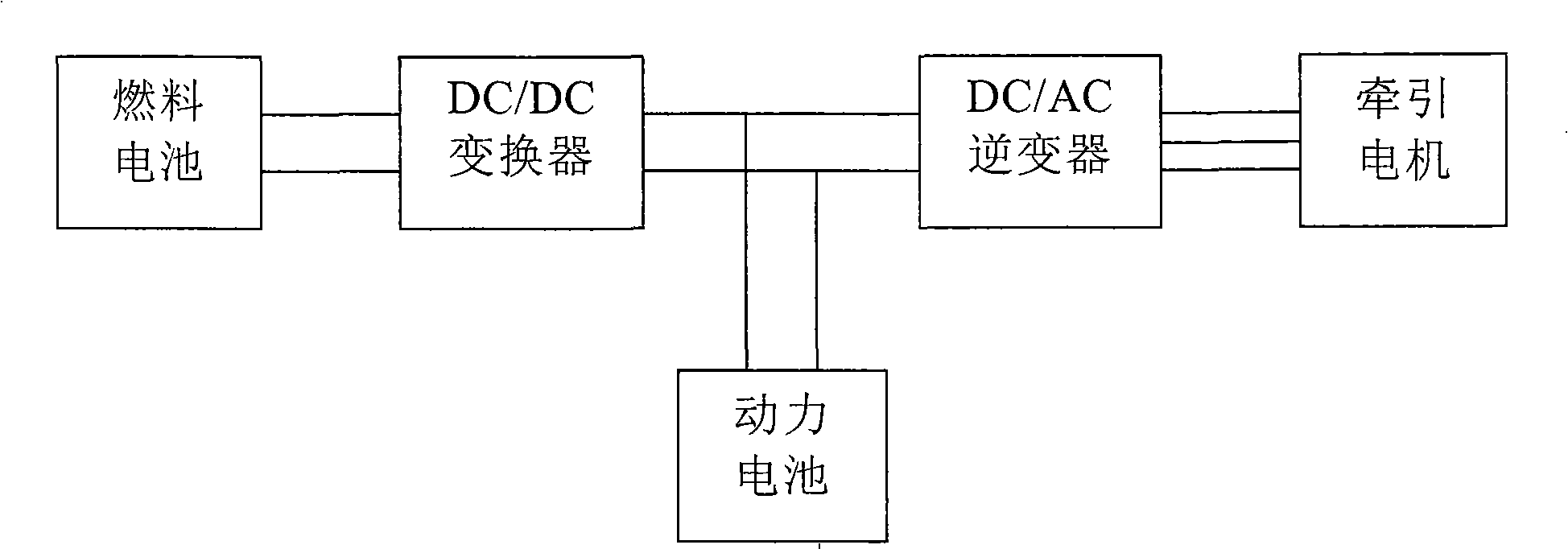

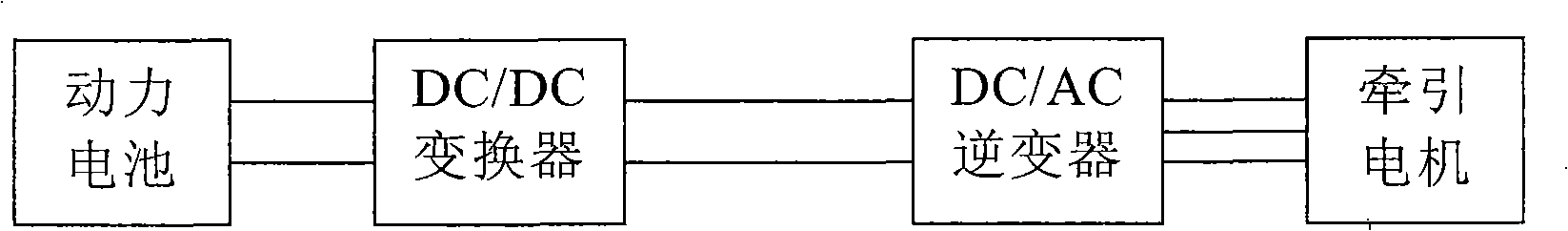

A technology of power electronics and packaging method, which is applied in the field of cooling and packaging of vehicle-mounted liquid-cooled power electronic controllers, can solve problems such as the limitation of the heat dissipation capacity of water channels and the density of heat dissipation columns, and achieve the effect of improving cooling efficiency and saving layout space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

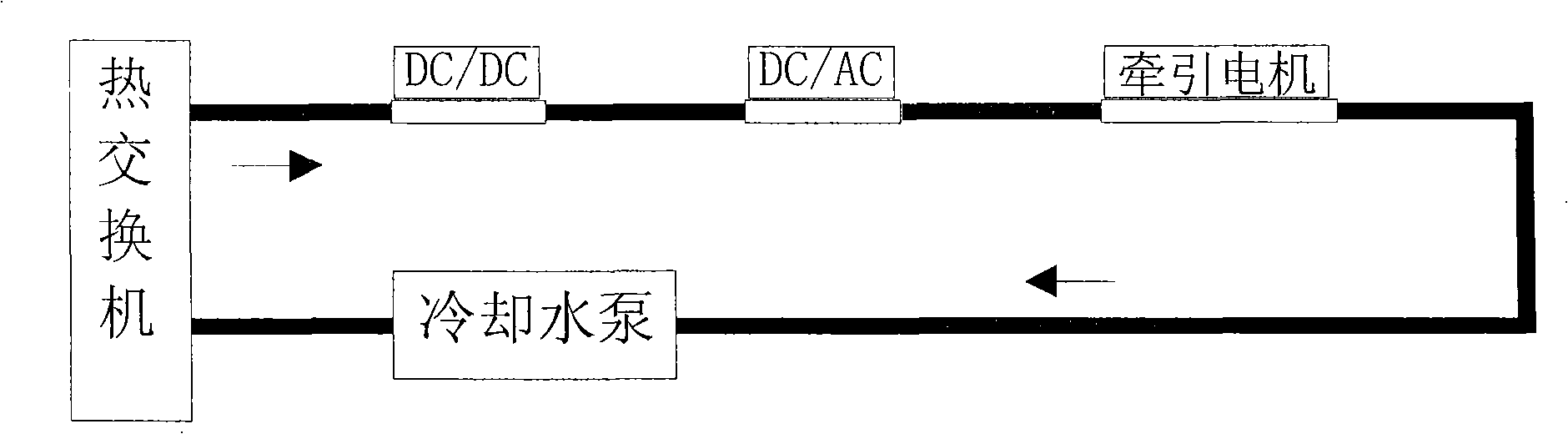

[0026] The cooling packaging method of the vehicle-mounted liquid-cooled power electronic controller of the present invention can be combined with Figure 5 , Figure 6 described as follows:

[0027] a. Build an integrated case 1 that can integrate the DC / DC converter 2 and the DC / AC inverter 3, and set two closely adjacent DC / DC converters and DC inverters 3 in the case. The water tanks 11 and 12 of the / AC inverter; the upper mouth of the two water tanks is made to be suitable for installing the broadside of the DC / DC converter and the DC / AC inverter. If serial water cooling is used, a pair of water inlet and outlet ports shall be provided for the two water tanks, and a communication port for cooling water shall be provided on the partition between the two water tanks; For the water inlet and outlet.

[0028] b. Install radiators 4 on the lower parts of the DC / DC converter 2 and the DC / AC inverter 3 respectively to form independent DC / DC cooling modules and DC / AC cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com