Sponge protection

A sponge and core material technology, applied in medical science, dentistry, cleaning teeth, etc., can solve problems such as interruption of work, breakage, and lateral displacement of the front end, and achieve the effects of preventing fever, preventing caries, and prolonging the duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

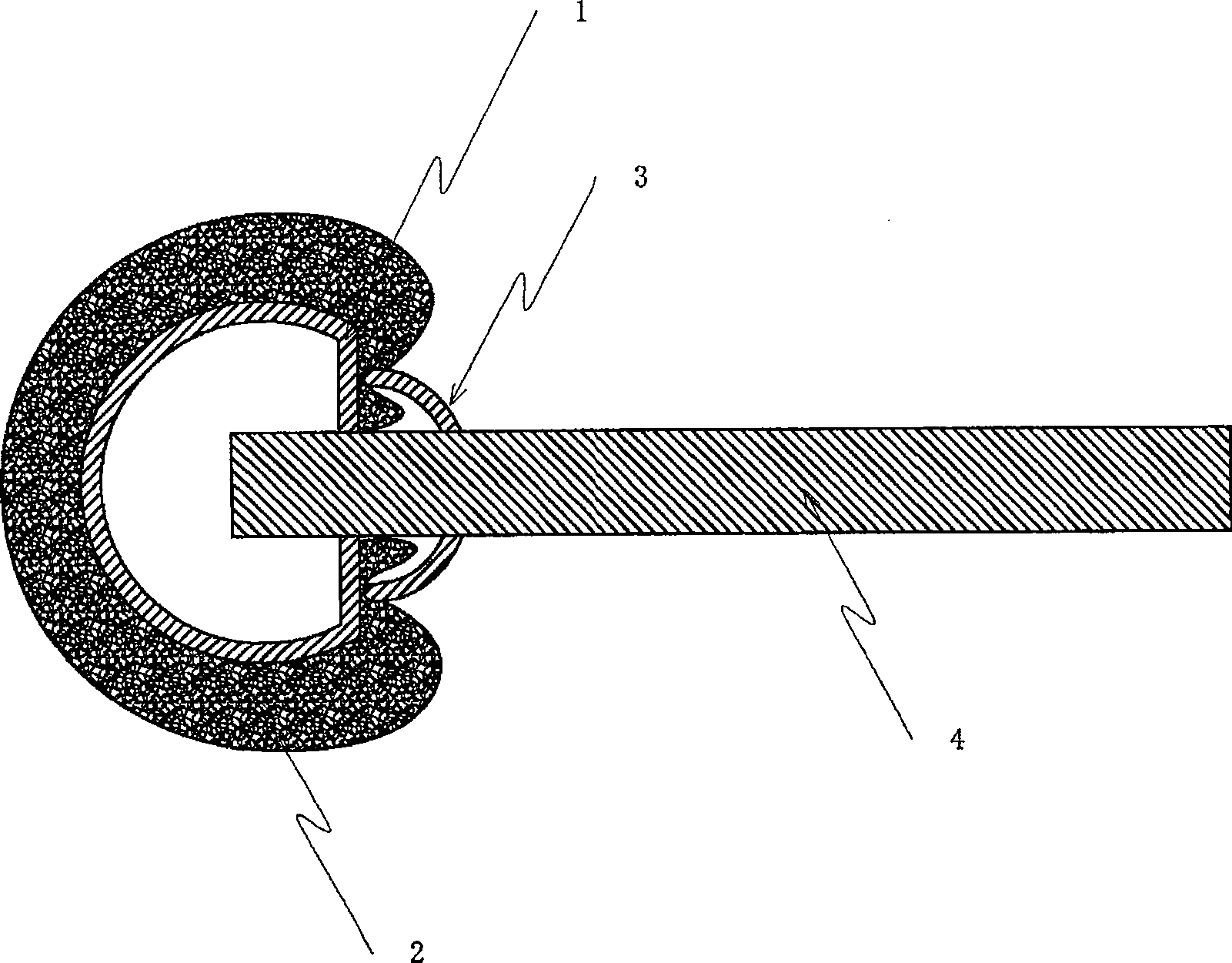

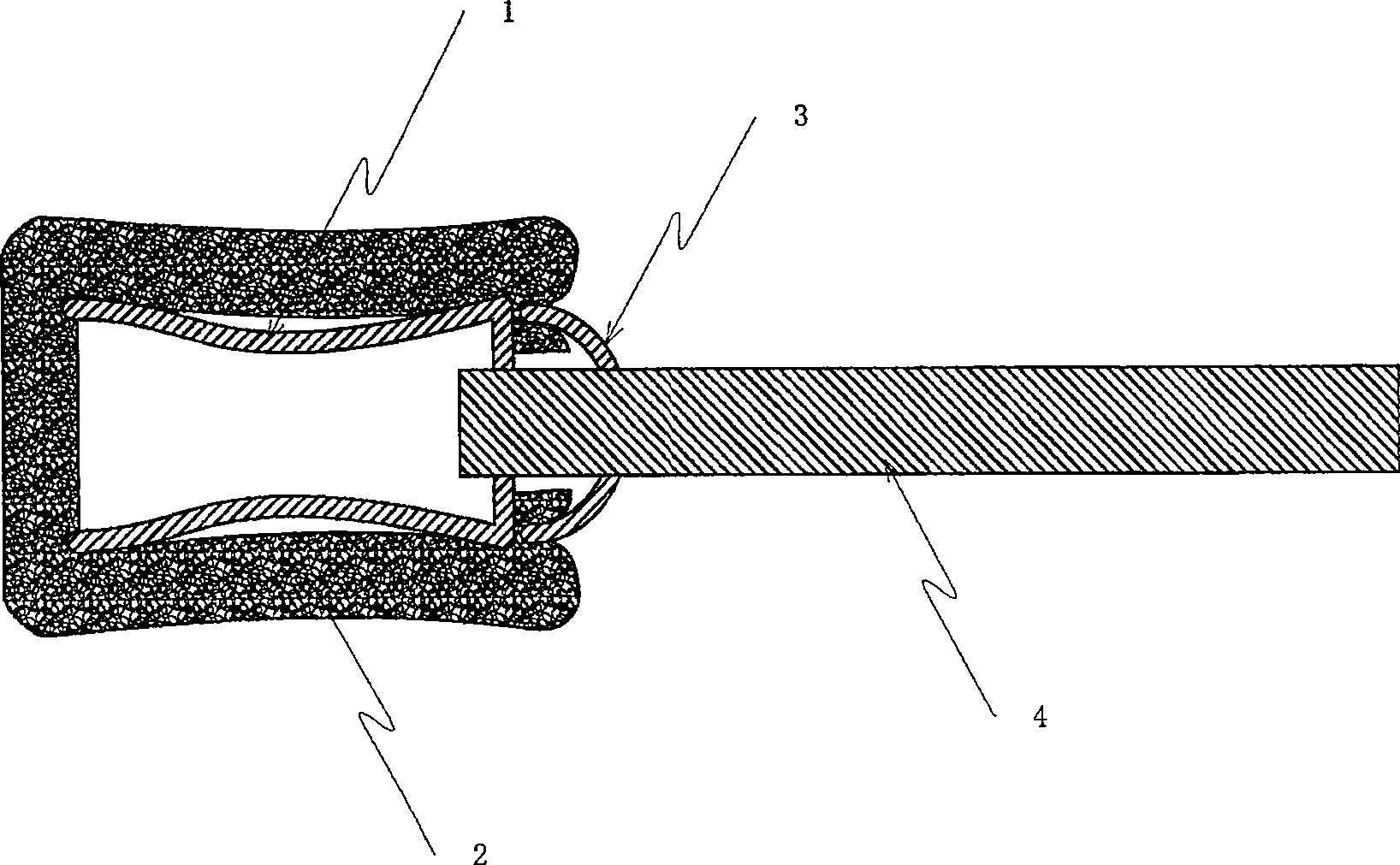

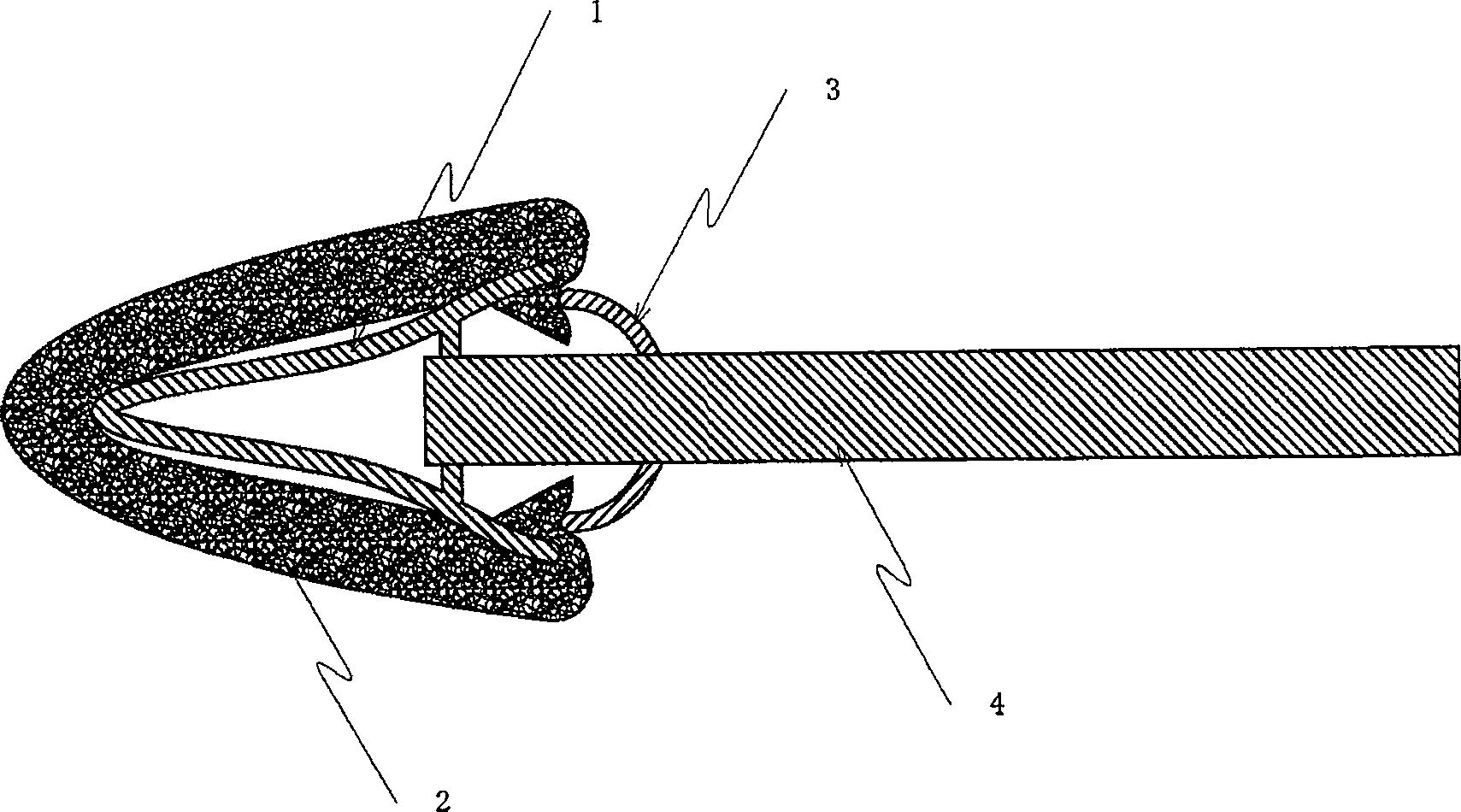

[0021] below with attached Figure 1 Embodiments of the present invention will be described first.

[0022] Figure 1 ~ Figure 3 It is an example of the embodiment of the present invention. In the drawings, the parts indicated by the same symbols represent the same objects. Although the basic structure is the same as that of the prior art shown in the drawings, the features of this drawing are as follows: figure 1 It is shown that a hydrophilic abrasive sponge is used on a core molded with silicone rubber or the like in the past.

[0023] Next, the operation of the above-mentioned drawings will be described.

[0024] Thus, the installation has Figure 1 ~ Figure 3 All kinds of sponge protection shown Figure 8 In the electric tooth crown grinding appliance shown in the oral cavity, the power switch 12 of the electric tooth crown grinding appliance is turned on while the sponge protection 13 is in contact with the tooth surface, and the constituent agent of the sponge prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com