Method for identifying ore phase of sphere blockage mine, and rotator used by the method

An identification method and technology of pelletizing, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problem of inability to intuitively reflect the difference between layer and layer organizational structure, inability to refine the reaction process by layer, Problems such as organizational structure separation, to achieve objective and accurate appraisal results, simple production, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

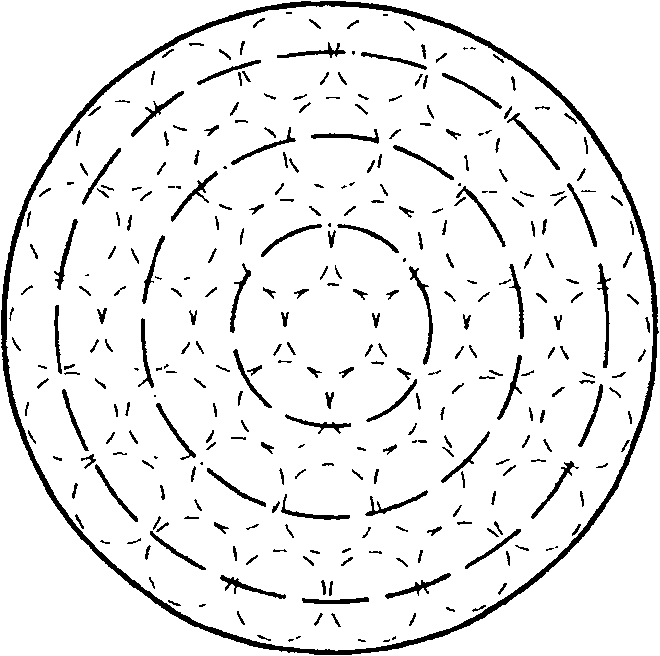

[0022] According to the method of the present invention, according to the spherical shape of the pellets and the layered distribution of the internal tissue structure, the idea of sub-ring identification is proposed, which uses a circular movement to identify each layer of mineral tissue, and counts the identification results by rings. Statistical results can be expressed in tables or histograms, which intuitively reflect the differences in organizational structure between layers, and can also be used to compare mineral samples in different periods. This method can obtain more accurate data on the organizational structure of pellets, and then can objectively and accurately reflect the factors that affect the performance of pellets based on the identification data.

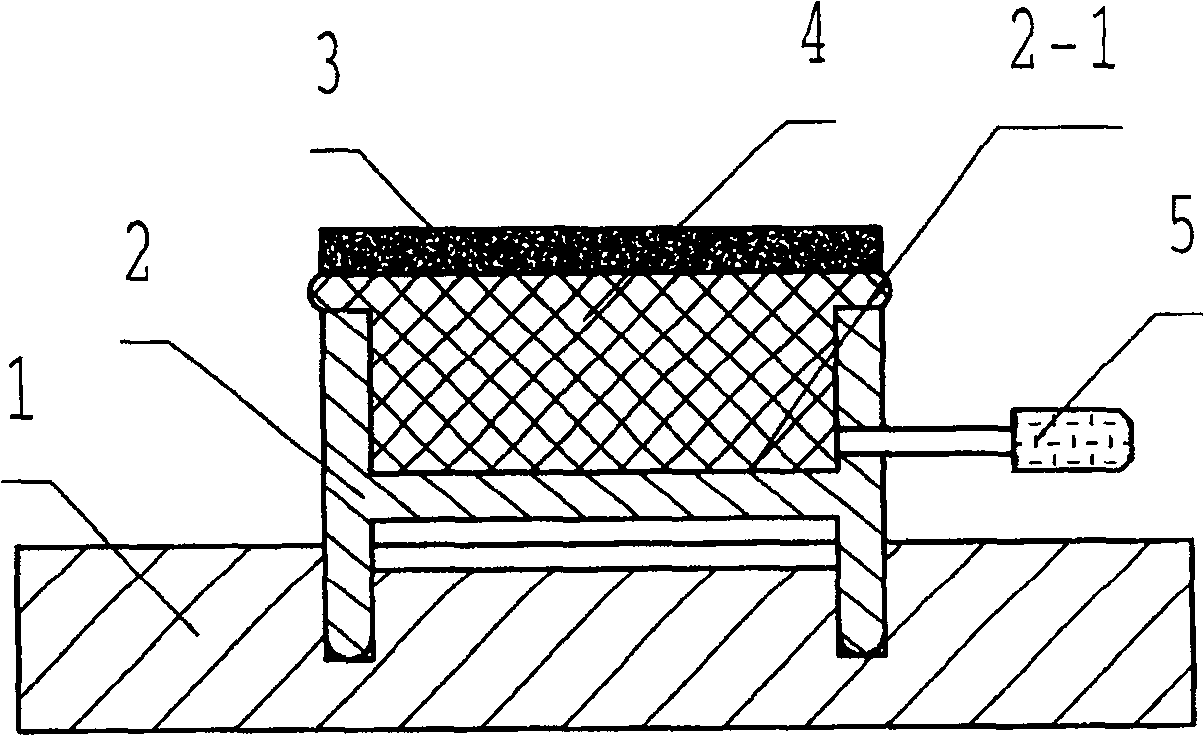

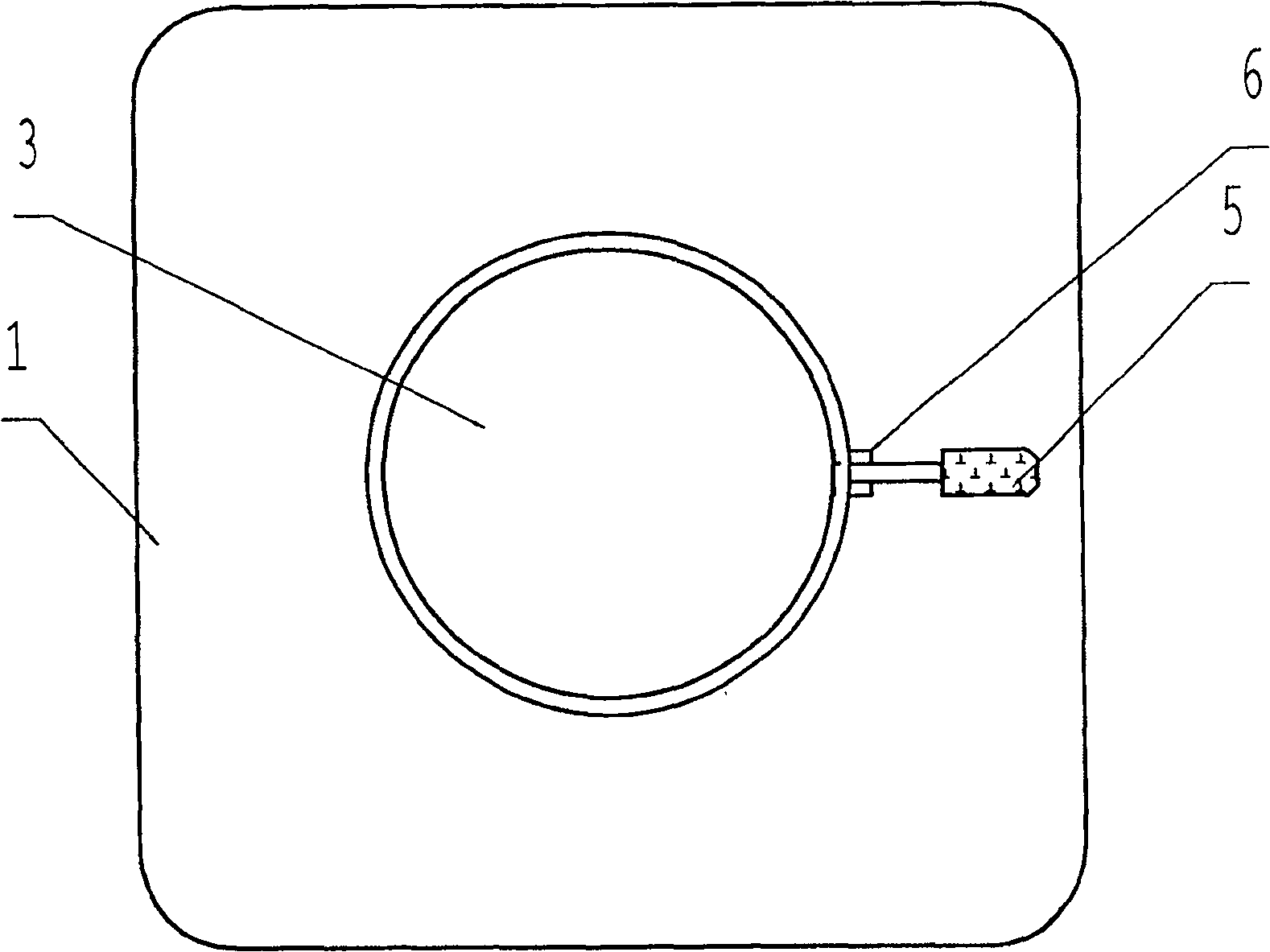

[0023] In order to facilitate the identification operation, the present invention also designs a rotating device for loop measurement. see figure 1 , figure 2 , The structure of the device includes a base 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com