Energy conversion method and device for ultrasonic liquid processing

A technology of liquid processing and transducing devices, applied in the field of ultrasound, which can solve the problems of large number of transducers, low processing capacity, and low ultrasonic field strength, and achieve the effects of simple equipment structure, improved manufacturing, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

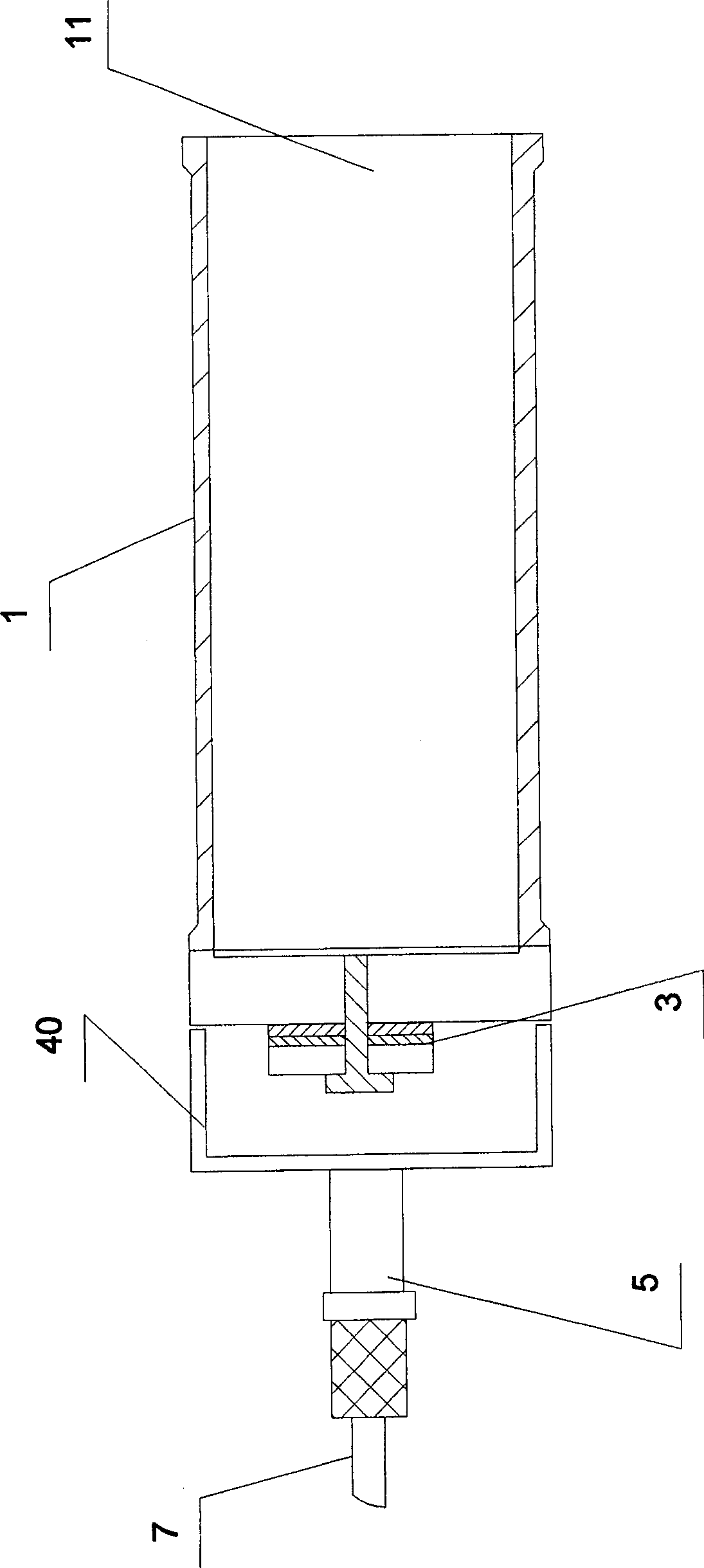

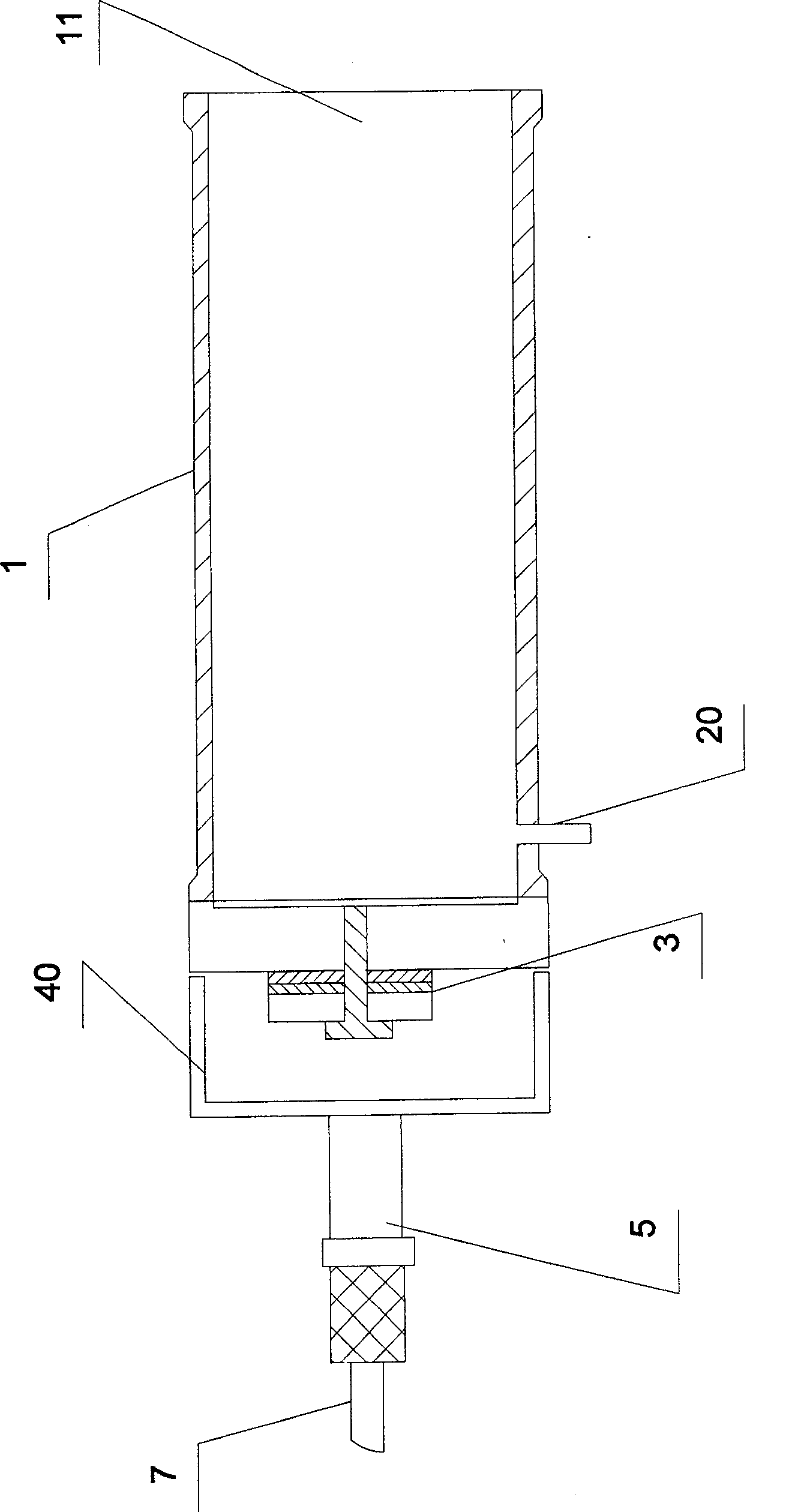

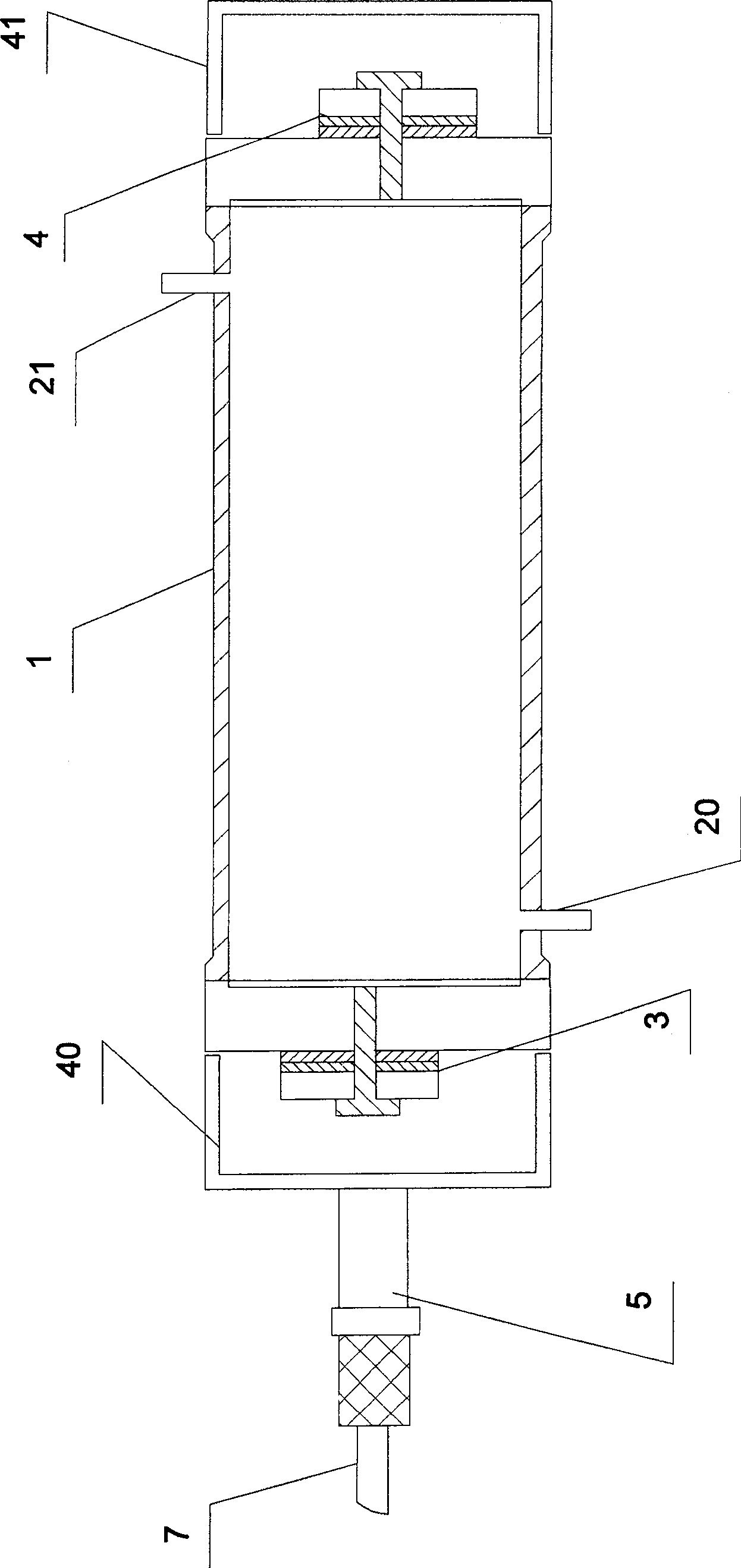

[0016] The invention provides an ultrasonic transducer device for liquid treatment. Such as figure 1 As shown, it is a schematic diagram of the first embodiment of the present invention. The liquid processing ultrasonic transducer includes at least one ultrasonic generator (not shown), a transducer 3, and a vibrating tube 1 filled with liquid. One end of the vibrating tube body 1 is provided with an opening 11, and the other end is equipped with a transducer 3, which is a longitudinal vibration transducer that can convert the ultrasonic waves generated by the ultrasonic generator into longitudinal high-energy mechanical vibrations. . The transducer 3 is fixedly connected to the vibrating tube body 1 by welding, which can just close the end of the vibrating tube body 1 . The transducer 3 is electrically connected to the ultrasonic generator through a cable 7 . A casing 40 capable of accommodating the transducer 3 is also provided on the outside of the transducer 3 , the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com