Device for extraction of shale oil by using oil shale and calcination of cement clinker

A technology for cement clinker and shale oil, which is applied in cement production, petroleum industry, preparation of liquid hydrocarbon mixture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

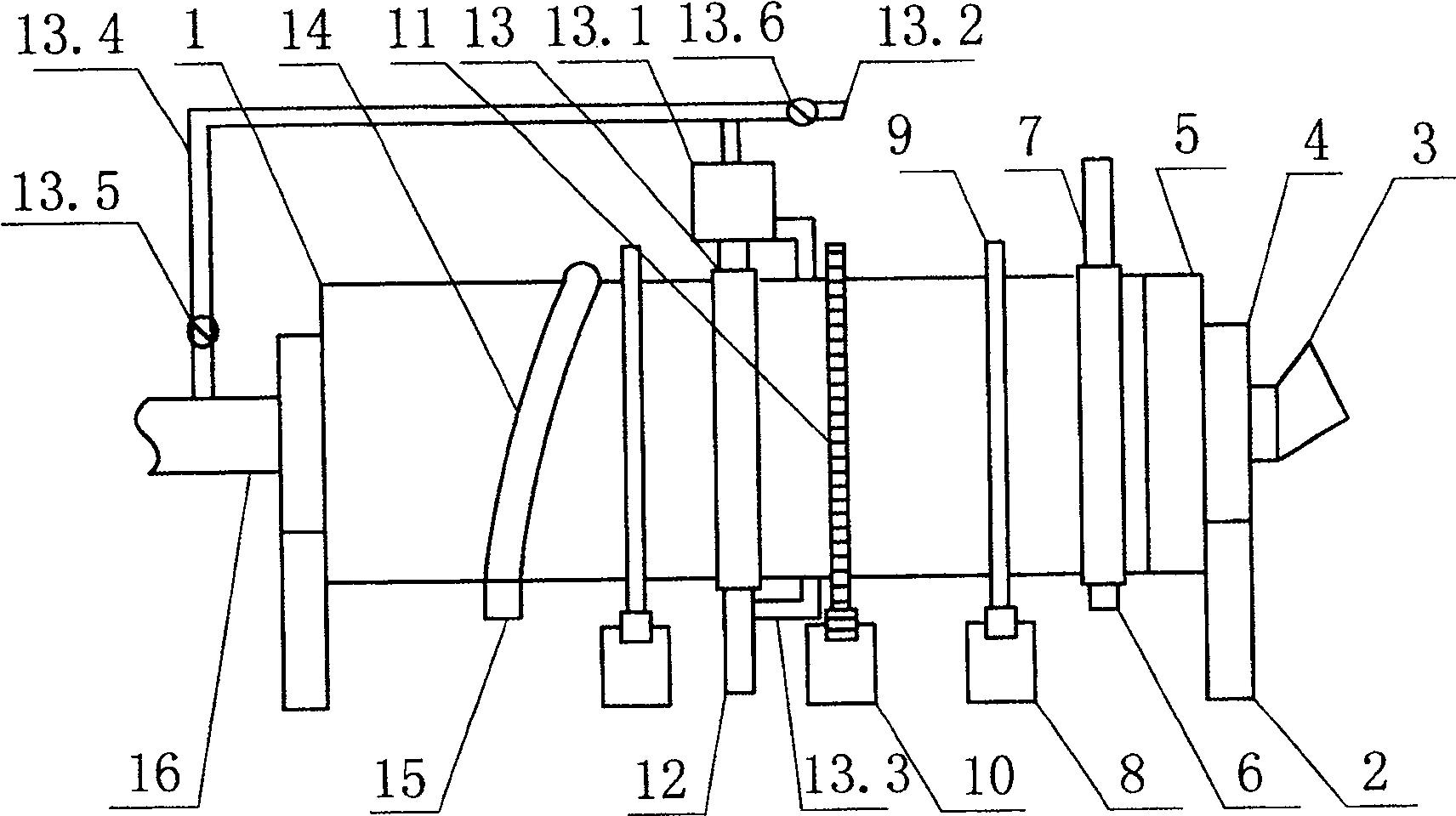

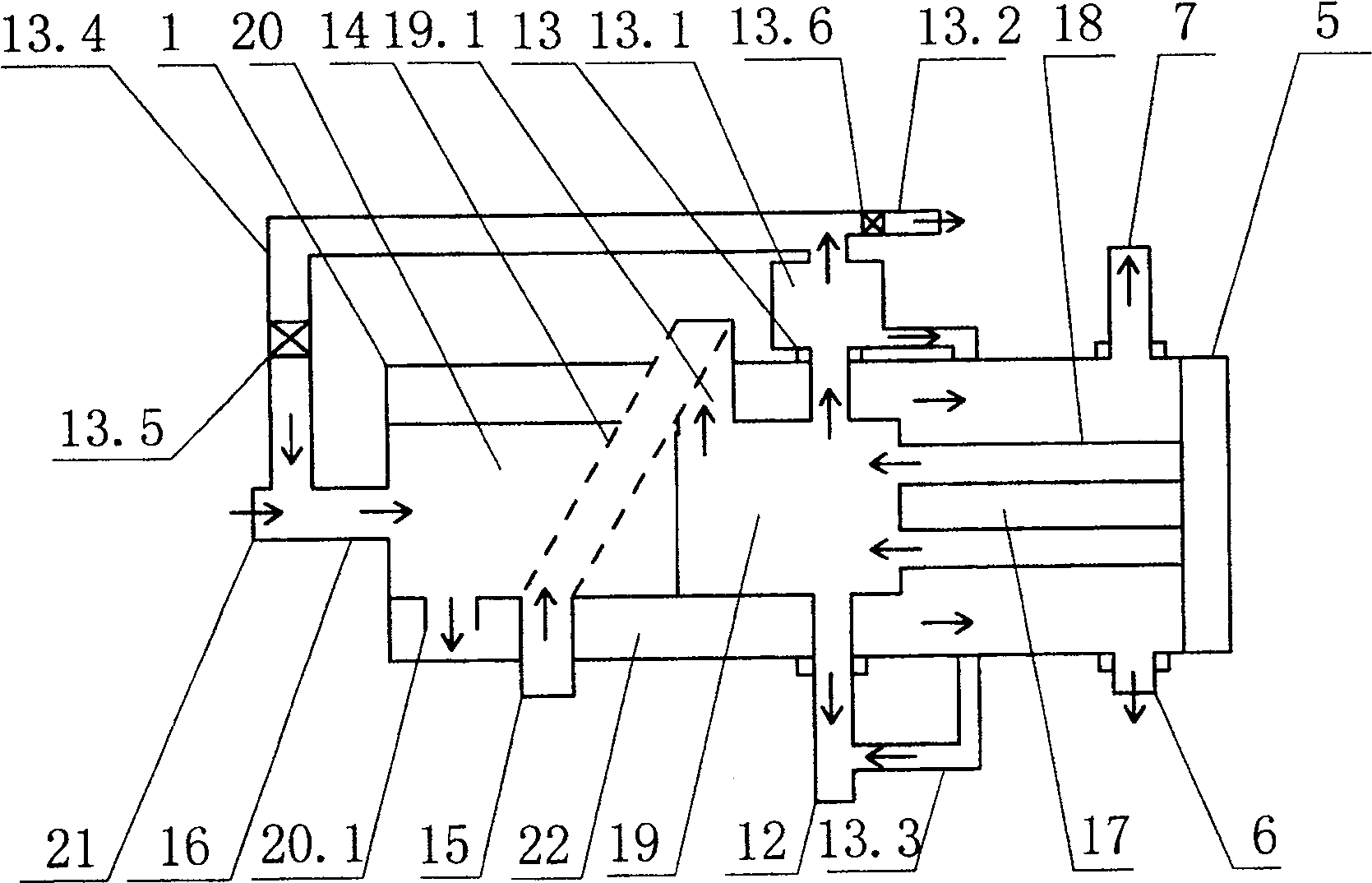

[0014] according to figure 1 and figure 2 As shown: the two ends of the revolving body 1 are respectively provided with revolving body rotators 4, and the revolving body rotators are rotatably connected with the revolving body support 2, and a feeding hopper 3 is provided on one side of the revolving body, and is connected with the material distribution propulsion Cement clinker outlet 6 and flue gas outlet 7 are provided on the outer side of the rotary body near the material distribution propeller, and a preheating chamber 17 is provided on the inner side of the rotary body. In the preheating chamber, the retort chamber and A plurality of material preheating conveying pipes 18 are connected in an annular arrangement between the material propulsion distributors;

[0015] A rotary body drive gear ring 11 is installed on the rotary body, and is connected to the rotary body driver 10 in transmission, and a rotary body rolling ring 9 is respectively connected to both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com