Preparation of silicon dioxide nano-tube

A technology of silicon dioxide and nanotubes, applied in the direction of silicon oxide, chemical instruments and methods, single crystal growth, etc., can solve the problems of low yield of nanotubes, small aspect ratio, large diameter distribution, etc., and achieve technological process Simple, large aspect ratio, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Weigh 0.04g of D,L-tartaric acid and add it to 10ml of ethanol, ultrasonically until the tartaric acid is completely dissolved, wherein the concentration of tartaric acid in the resulting solution is 0.027mol / L;

[0027] 2) adding 4ml mass percent concentration to the solution obtained in the above step 1) is 28% ammonia solution;

[0028] 3) In the stirring state, add 1.5 ml of ethyl orthosilicate dropwise to the solution obtained in step 2) within 1 hour, and after the dropwise addition, let stand for 10 hours to obtain a white gel;

[0029] 4) The above white gel was repeatedly washed with a large amount of deionized water ultrasonically, and the obtained white floc was dried at 80° C. for 2 hours to obtain the silica nanotubes of the present invention.

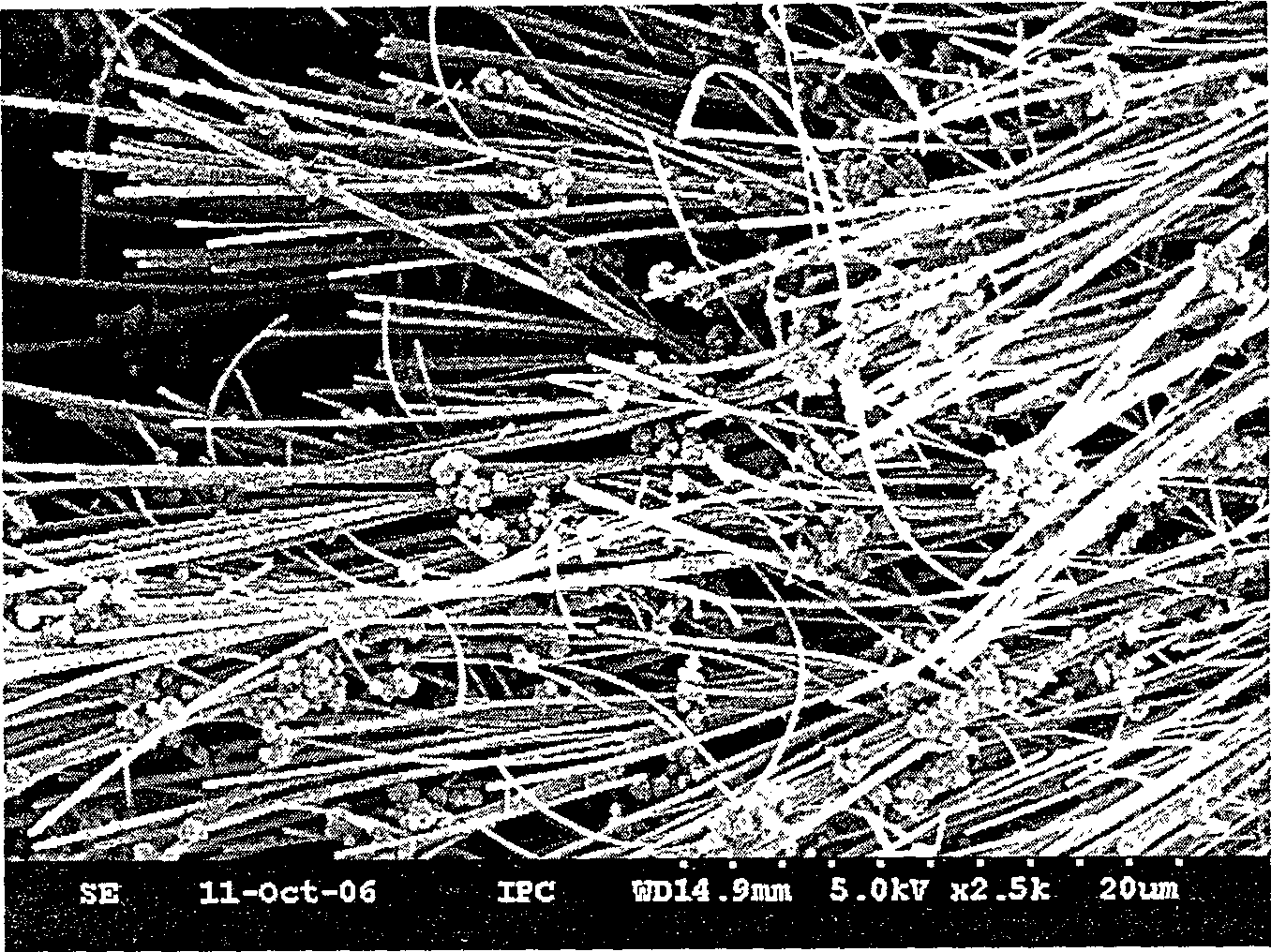

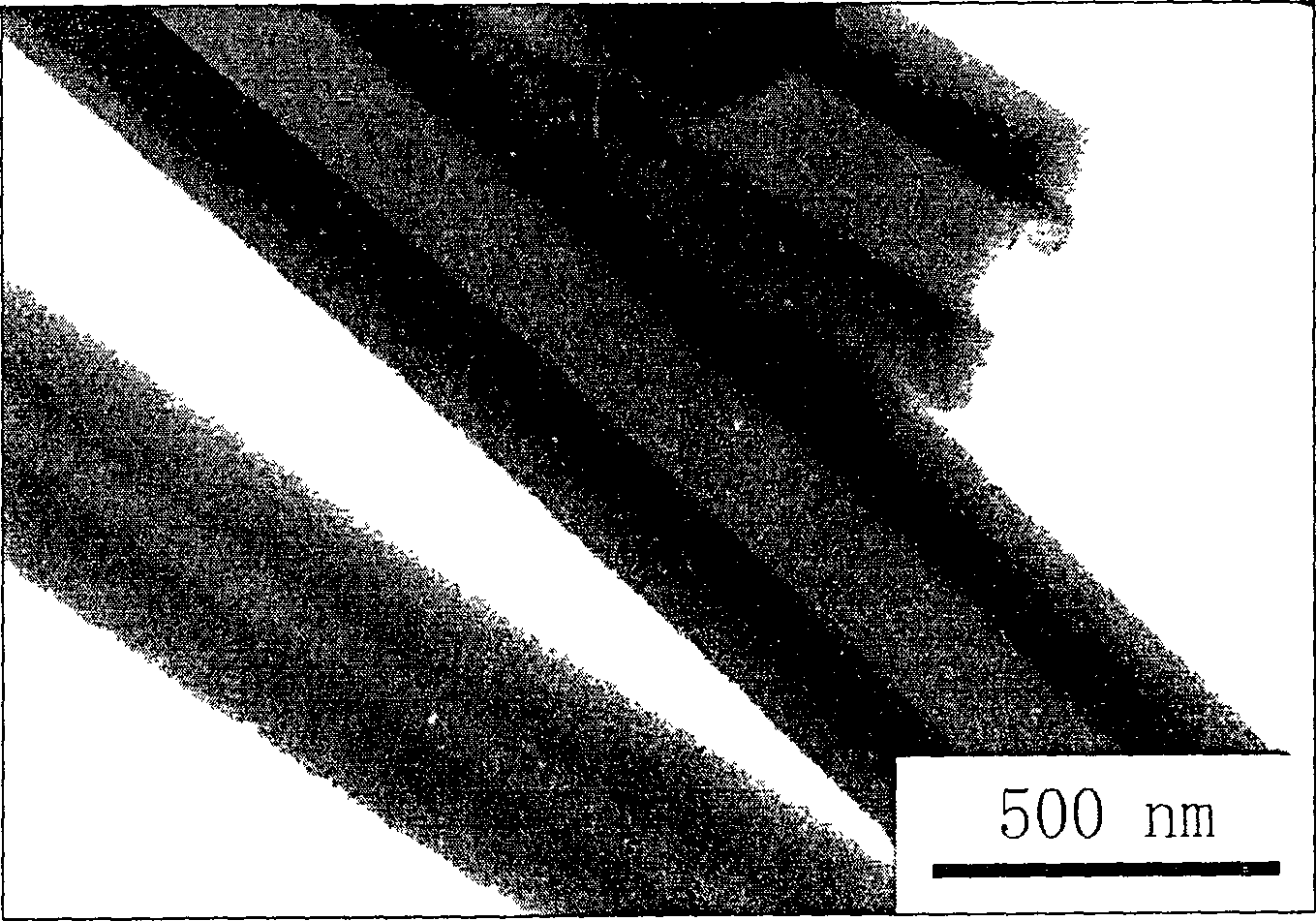

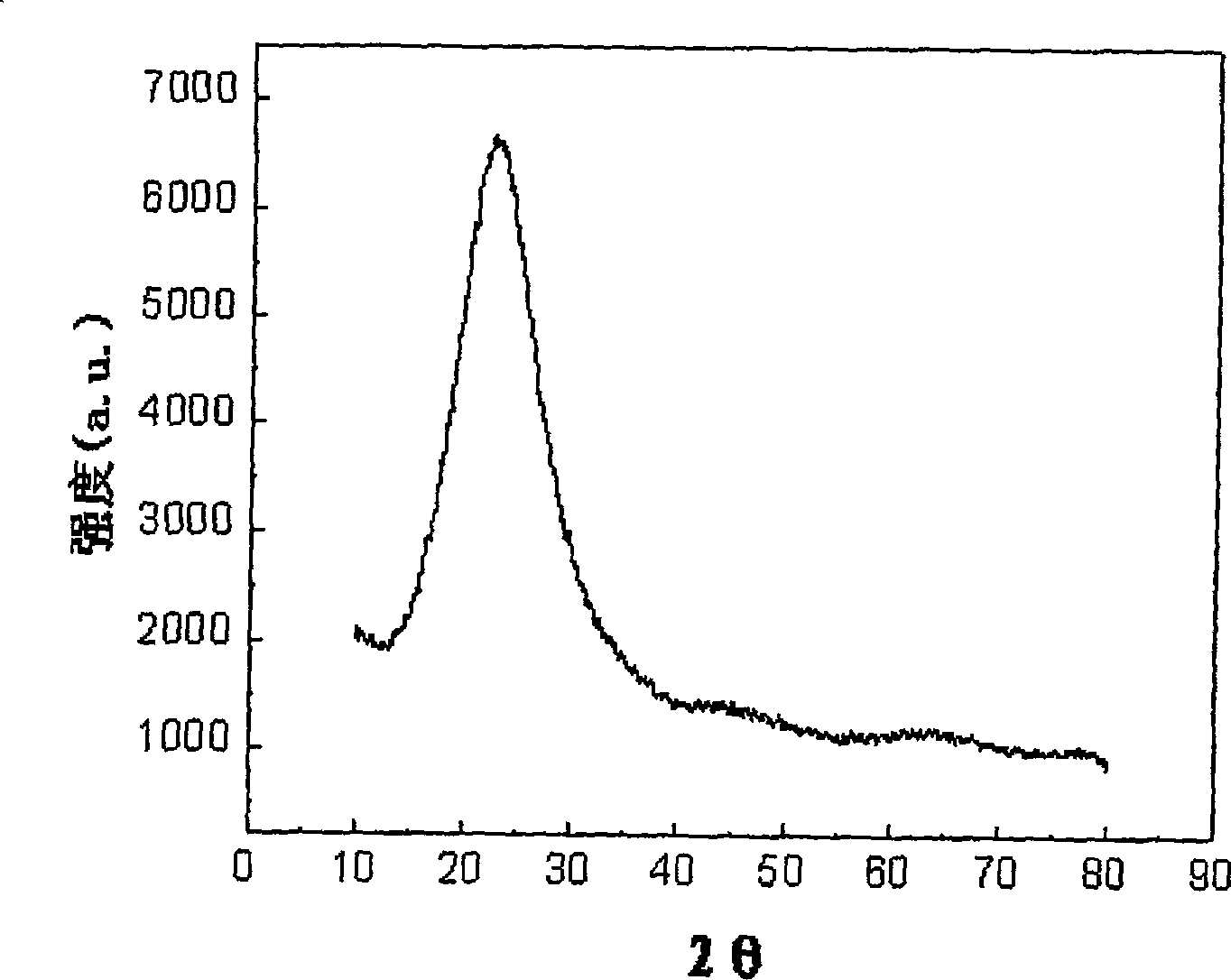

[0030] figure 1 Provided the silicon dioxide nanotube scanning electron microscope (SEM) picture that present embodiment prepares, can see from the figure, the silicon dioxide nanotube gained in embodiment 1 is ...

Embodiment 2

[0032] 1) Weigh 0.015g of L-tartaric acid and add it to 10ml of ethanol, ultrasonically until the tartaric acid is completely dissolved, wherein the concentration of tartaric acid in the resulting solution is 0.01mol / L;

[0033] 2) adding 2ml mass percent concentration to the solution obtained in the above step 1) is 24% ammonia solution;

[0034] 3) Under stirring, add 0.6 ml of propyl orthosilicate to the solution obtained in step 2) at one time, and then let it stand for 24 hours to obtain a white gel;

[0035] 4) The above white gel was repeatedly washed with a large amount of deionized water ultrasonically, and the obtained white floc was dried at 50° C. for 10 hours to obtain the silica nanotubes of the present invention.

Embodiment 3

[0037] 1) Weigh 0.06g of D,L-tartaric acid and add it to 10ml of ethanol, and sonicate until the tartaric acid is completely dissolved, wherein the concentration of tartaric acid in the resulting solution is 0.04mol / L;

[0038] 2) adding 6ml mass percent concentration to the solution obtained in the above step 1) is 26% ammonia solution;

[0039] 3) Under stirring, add 3.2 ml of butyl orthosilicate dropwise to the solution obtained in step 2) within 2 hours. After the dropwise addition, a white gel is obtained;

[0040] 4) The above white gel was immediately washed repeatedly with a large amount of deionized water ultrasonically, and the obtained white floc was dried at 65° C. for 6 hours to obtain the silica nanotubes of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com