Monophase catalyzed methanol gasoline

A methanol-gasoline, high-ratio technology, applied in the field of single-phase catalytic high-ratio methanol gasoline, can solve the problems of methanol gasoline and petroleum gasoline not easy to mix, unsuitable saturated vapor pressure, poor mutual solubility and easy knocking, etc., and achieve good combustion economy , solve the effect of poor mutual melting and improve octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

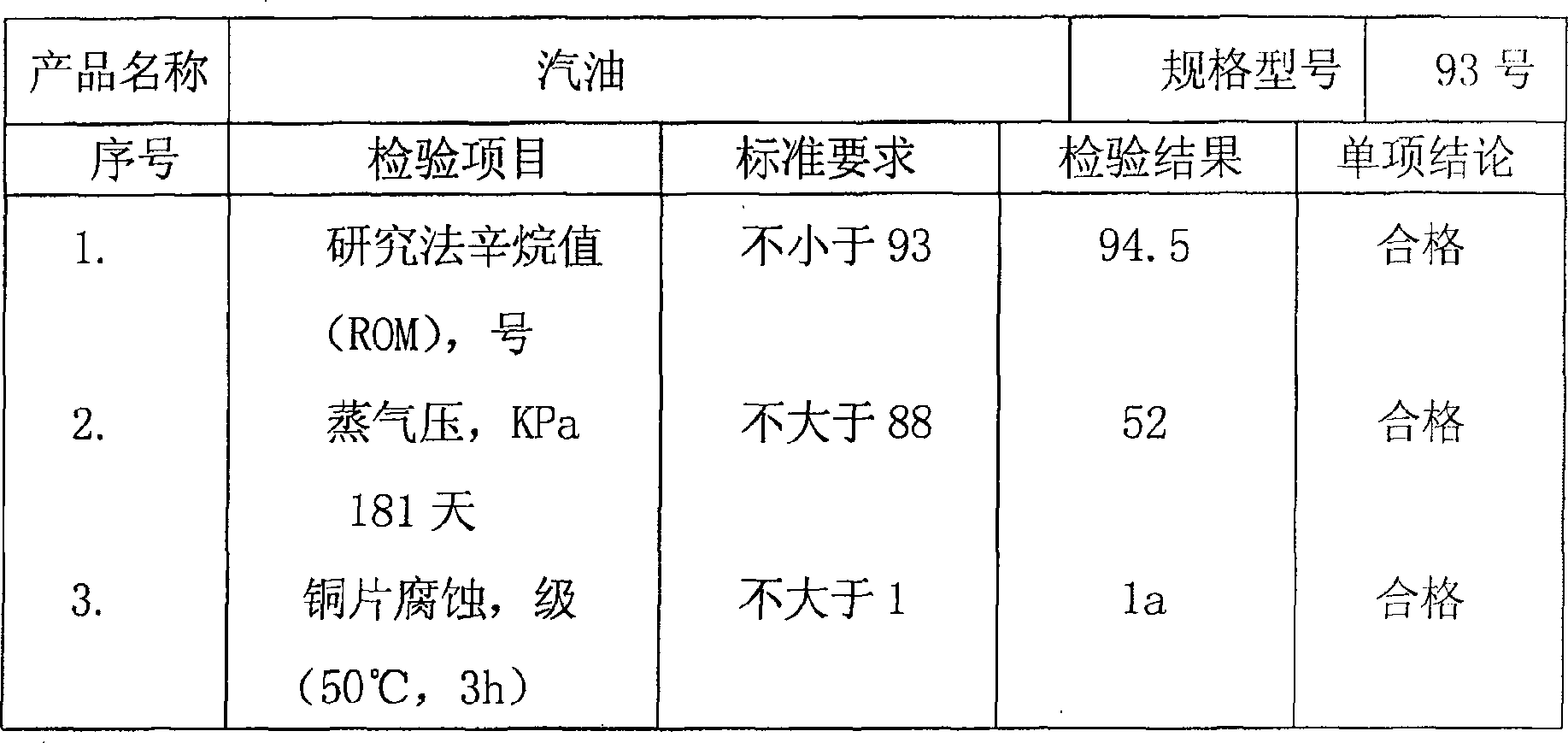

[0018] The single-phase catalytic high-ratio methanol gasoline of the present invention is composed of 20 parts of 99.5% methanol, 75 parts of 93# gasoline, 3 parts of methyl tert-butyl ether, 0.1 part of epoxy soybean oil, diphthalic acid di 0.1 part of butyl ester, 0.1 part of diallyl phthalate, 2 parts of acetone, 2 parts of ethyl acetate, and 0.1 part of antistatic agent are added to the storage tank in order according to the above order, and the finished product can be obtained without stirring.

Embodiment 2

[0020] The single-phase catalyzed high-ratio methanol gasoline of the present invention is composed of 20 parts of 99.5% methanol, 70 parts of 93# gasoline, 5 parts of methyl tert-butyl ether, 0.3 part of epoxy soybean oil, diphthalic acid 0.2 parts of butyl ester, 0.2 parts of diallyl phthalate, 2 parts of acetone, and 2 parts of ethyl acetate are added to the storage tank in sequence according to the above order, and the finished product can be obtained without stirring.

Embodiment 3

[0022] The single-phase catalytic high-ratio methanol gasoline of the present invention is composed of 40 parts of 99.5% methanol, 50 parts of 93# gasoline, 6 parts of methyl tert-butyl ether, 0.3 part of epoxy soybean oil, diphthalic acid di 0.3 parts of butyl ester, 0.3 parts of diallyl phthalate, 3 parts of acetone, 3 parts of ethyl acetate, and 0.3 parts of preservative are added to the storage tank in order according to the above order, and the finished product can be obtained without stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com