Heat pipe

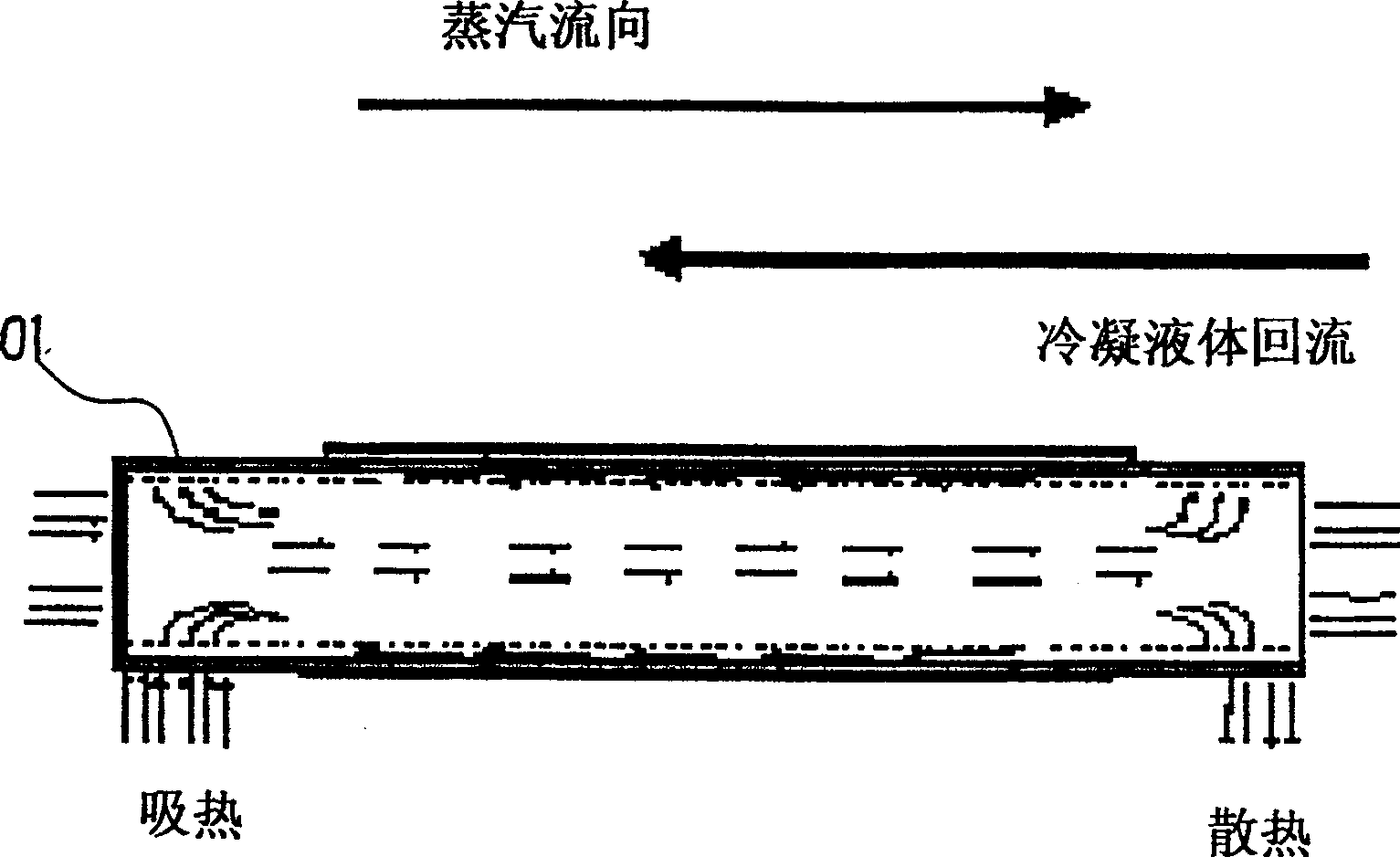

A technology of heat pipes and copper pipes, which is applied in the field of computer accessories, can solve problems such as hindering water return flow, broken water flow, and weak pipe structure, so as to avoid excessive fusion, increase water flow space, and reduce manufacturing risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention.

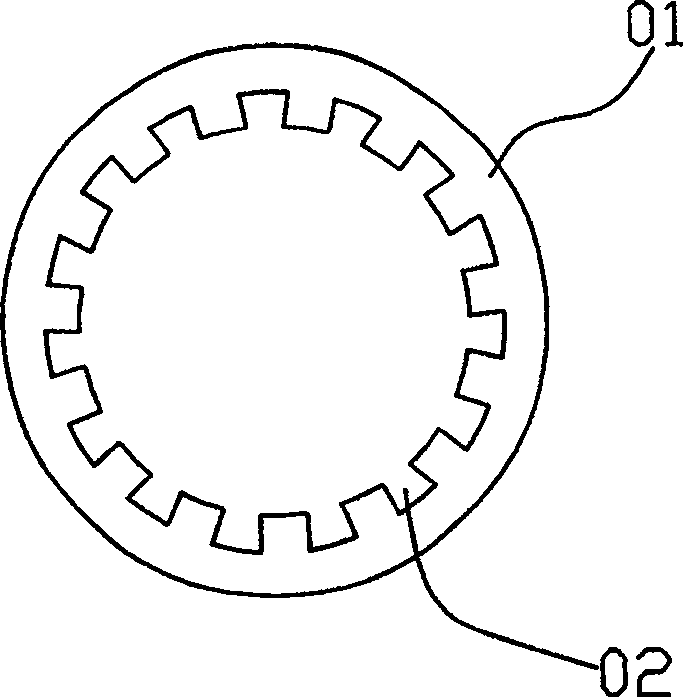

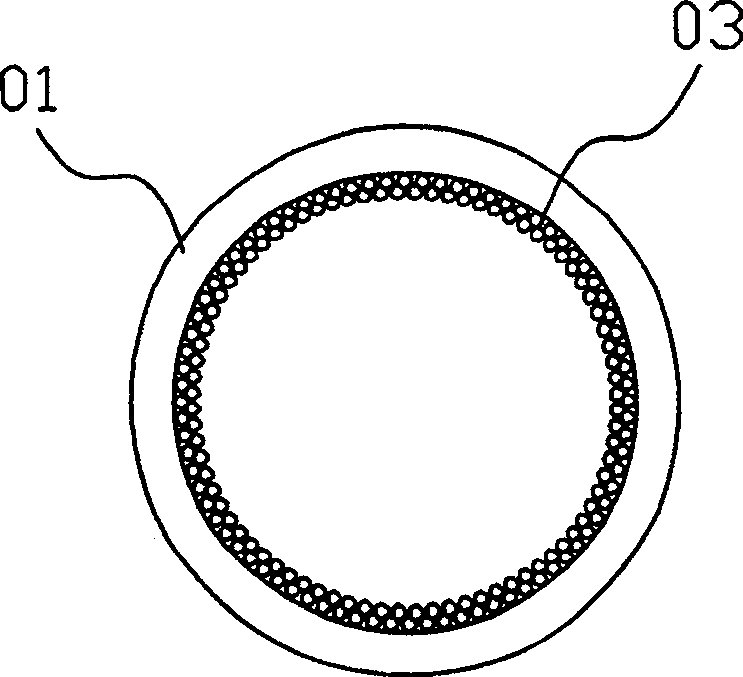

[0023] As shown in accompanying drawing 3: the heat pipe of the present invention has a hollow copper tube 10, a copper ball powder layer 20 is sintered in the copper tube 10, and a layer of copper ball powder layer 20 is attached to the inner wall of the copper tube 10 below 800 ℃. Copper produces an insulating layer 30 for sintering reaction, and the copper ball powder layer 20 and the copper tube 10 can be separated from each other.

[0024] The structure and manufacturing process of the present invention are different from general heat pipes. Traditional heat pipes are sintered together with copper ball powder, which is integrally sintered. However, the present invention first attaches a layer of barrier layer 30 to the inner wall of the copper tube 10, so that the copper ball powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com