Electromagnetic induction type plasma flat backlight source

A plasma and electromagnetic induction technology, applied in the field of plasma panel backlights, can solve the problems of environmental pollution, low coupling efficiency of panel backlights, poor startup performance, etc., and achieve a wide range of applicable voltages, uniform brightness, and discharge coupling efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

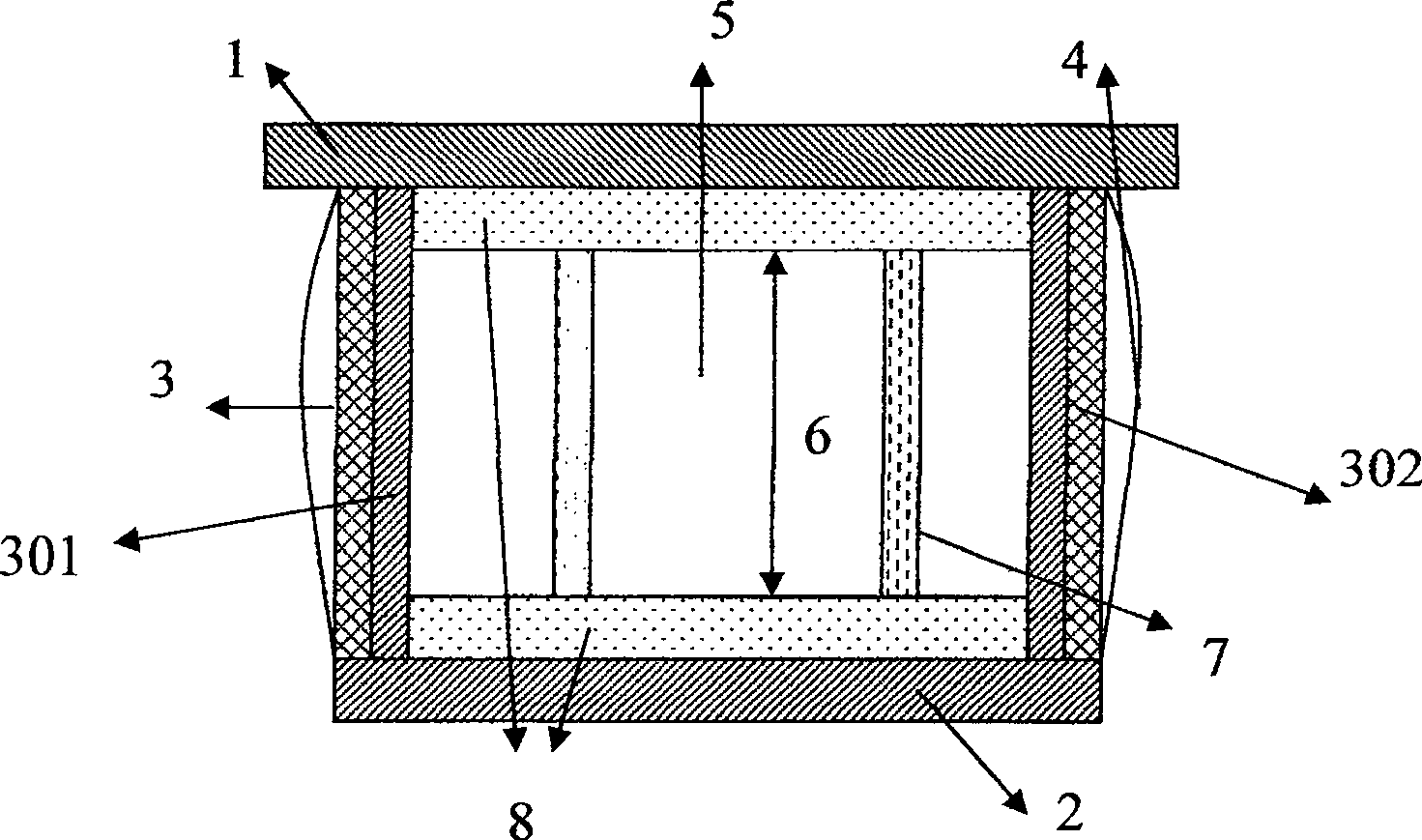

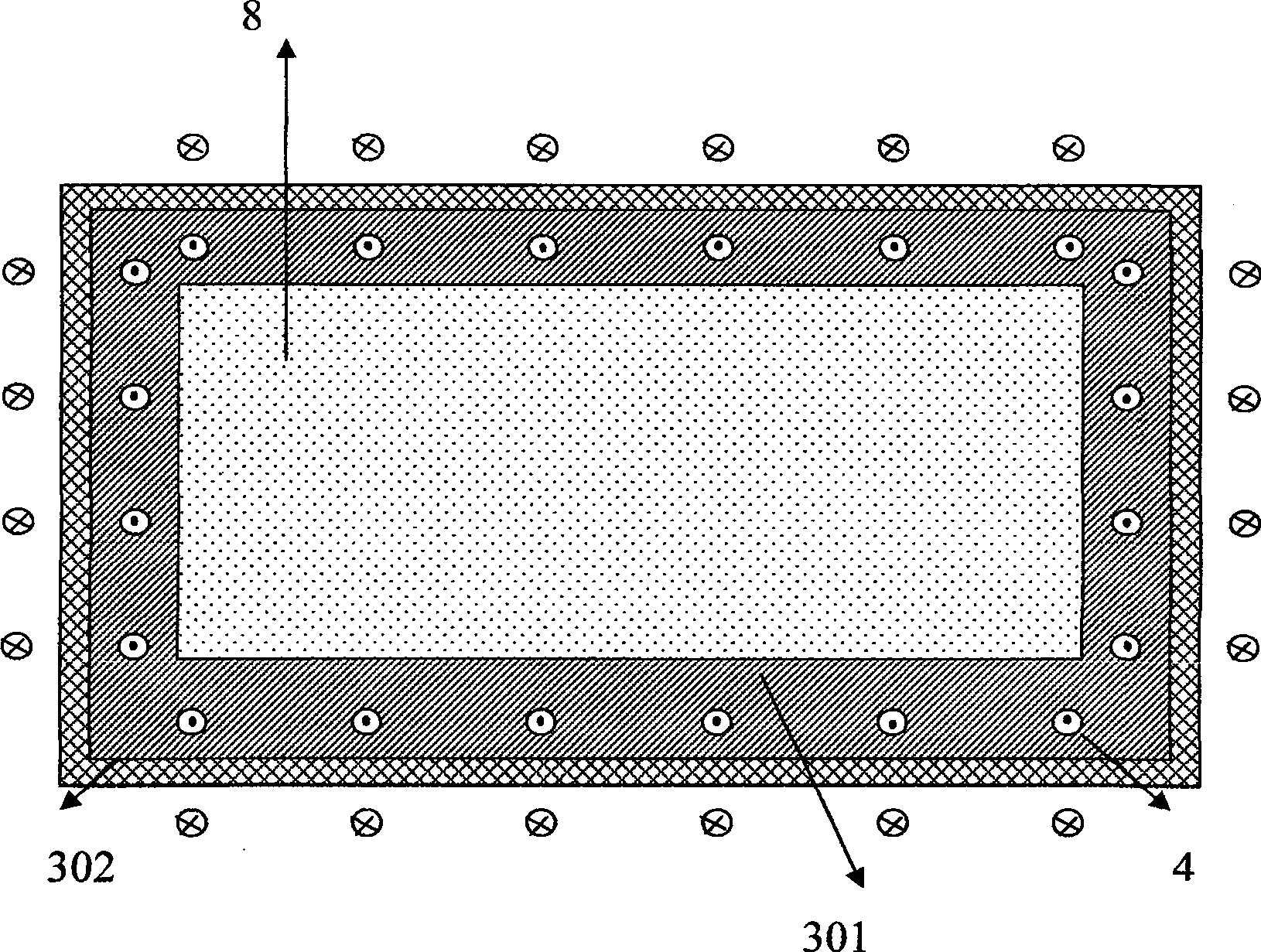

[0033] Such as figure 1 , figure 2 As shown, an electromagnetic induction plasma flat panel backlight includes a transparent front substrate 1 and a rear substrate 2 arranged in parallel, and is characterized in that a skeleton 3 is arranged between the front substrate 1 and the rear substrate 2, and is sealed to form a flat The discharge space 5 of the backlight is filled with xenon gas or neon-xenon mixed gas, the helical coil 4 is arranged on the skeleton 3 , and the inner surfaces of the front substrate 1 and the rear substrate 2 are coated with fluorescent powder 8 .

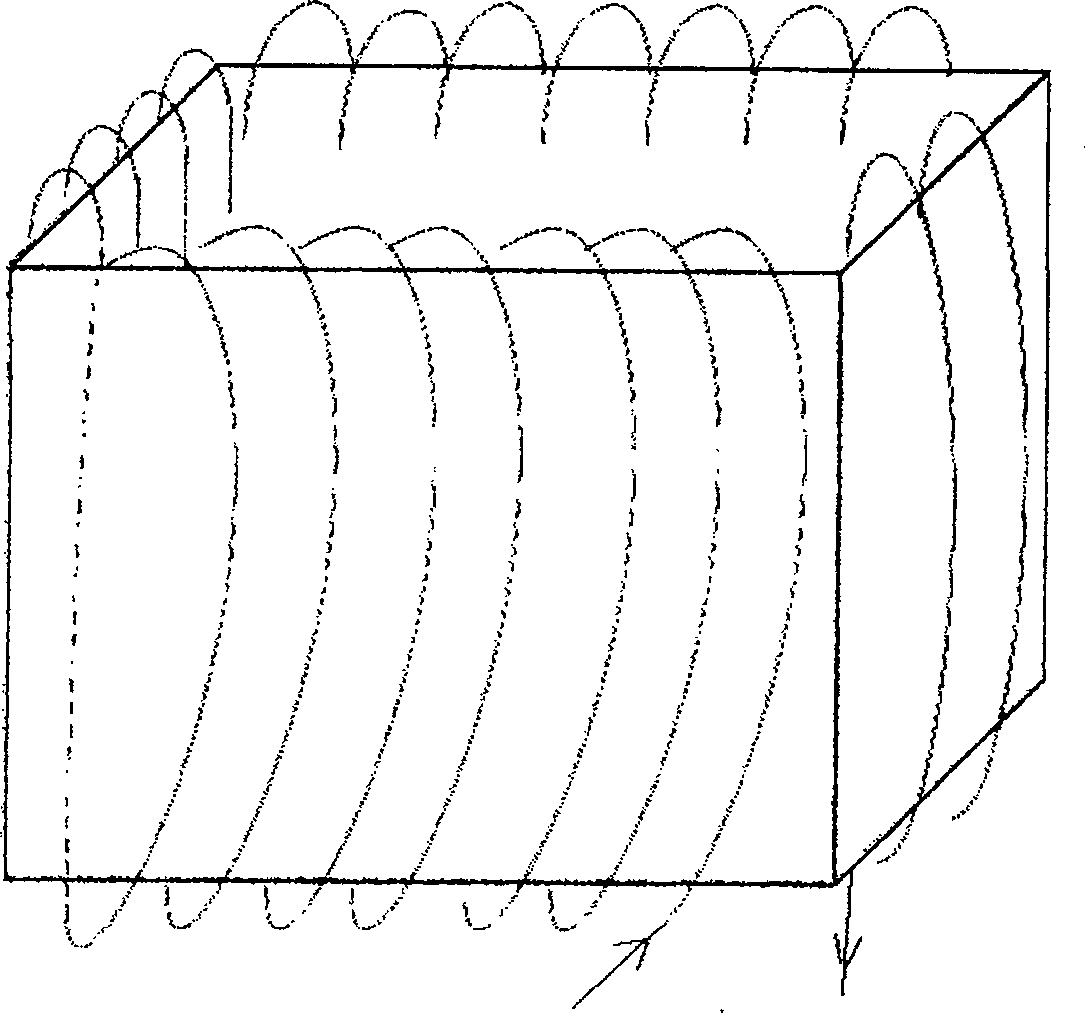

[0034] The skeleton 3 is composed of a side plate 301 and an annular iron core 302 sleeved on the outer periphery of the side plate 301. The side plate is sealed with the front substrate 1 and the rear substrate 2 to form a discharge space 5. The spiral coil 4 is sleeved on the annular iron core 302. , so that the entire annular core 302 is located in the helical coil 4, such as image 3 shown. The wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com