Road surface crusher

A crusher and fuselage technology, applied in the field of road crushers and road construction devices, can solve the problems of slow construction progress, high working noise, high compressive strength, etc., to reduce maintenance costs, improve crushing efficiency, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

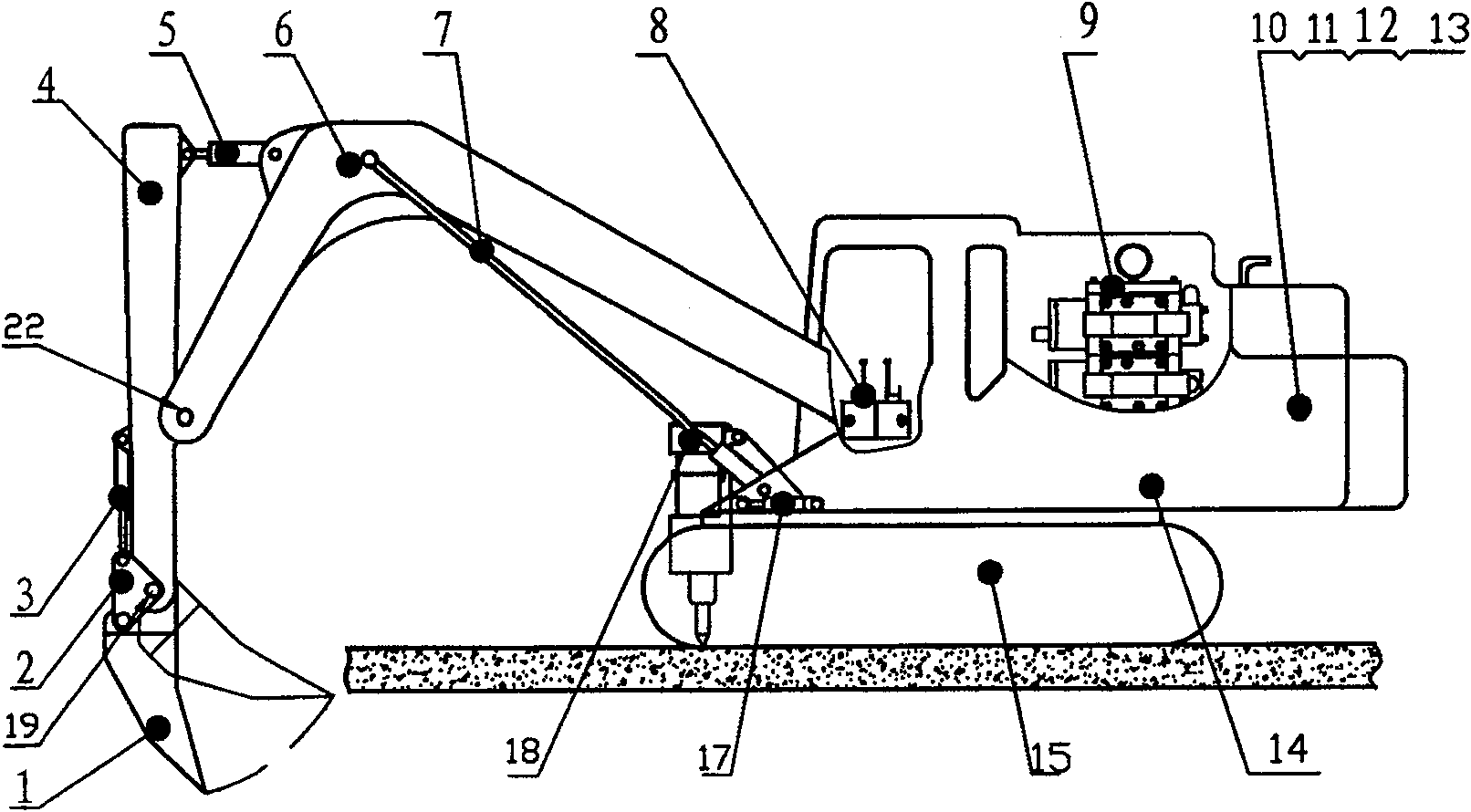

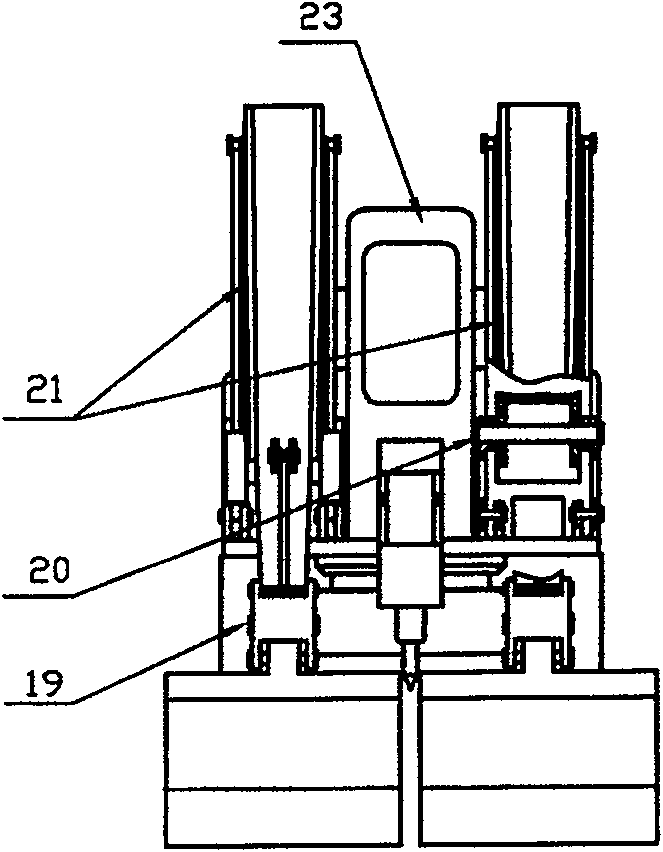

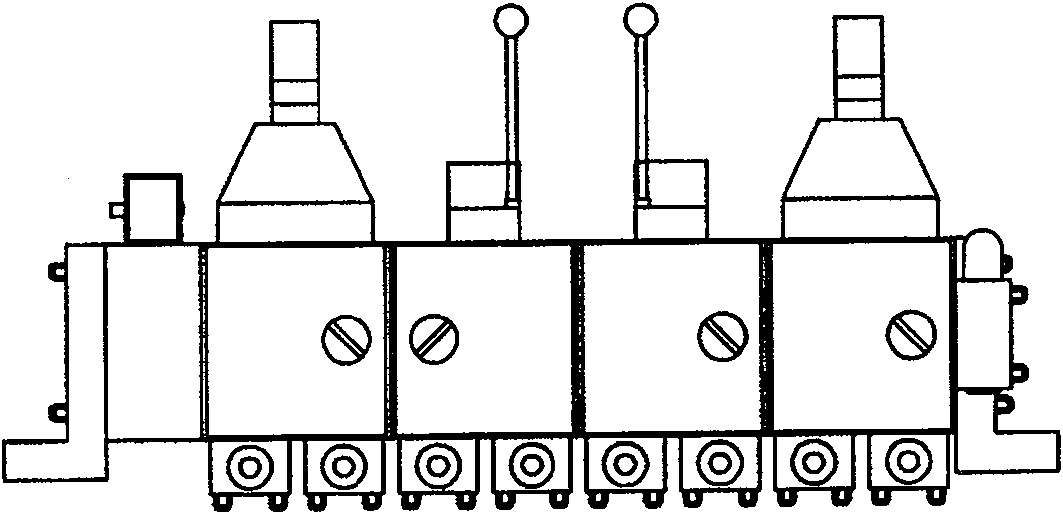

[0021] figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 Yes figure 1 left view of . from figure 1 , figure 2 It can be seen that the pavement breaker is composed of a crawler chassis 15 and a fuselage 14. The present invention uses a 171-type chassis of China Geological Equipment Corporation, and the crawlers of the chassis are two groups arranged in parallel. The fuselage 14 is supported by a chassis 15 , and the engine 10 is provided on the fuselage 14 . The improvement of the present invention is that the traditional breaking hammer is canceled, and the wrench 1 is used instead to pull the road surface from the side of the roadbed. In order to make the wrench 1 move flexibly, the wrench 1 is connected with the fuselage 14 through an arm transmission mechanism. The head end of the arm transmission mechanism is movably connected to the fuselage 14 through pin one 20 which can rotate around it, and the end of the arm transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com