Method for determining quality of coat

A quality judgment and coating technology, which is applied in the field of evaluating the coating quality of coated sheets, can solve problems such as large differences in evaluation results and difficult comparisons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Concrete operating steps of the present invention are as follows:

[0013] 1) Perform uniaxial tension on the sample (1mm thick hot-dip galvanized sheet) on a tension and compression testing machine;

[0014] 2) When stretching to 3100N, carry out load protection, and measure the cross-sectional area of the sample to obtain the tensile or compressive stress at this time;

[0015] 3) In the process of load preservation, the scratch tester performs multi-point vertical compressive stress loading on the parallel section of the specimen. The loads are: 30N, 50N, 70N, 90N, 110N, 130N, 150N, 170N, 190N, point by point The distance between them is 5mm;

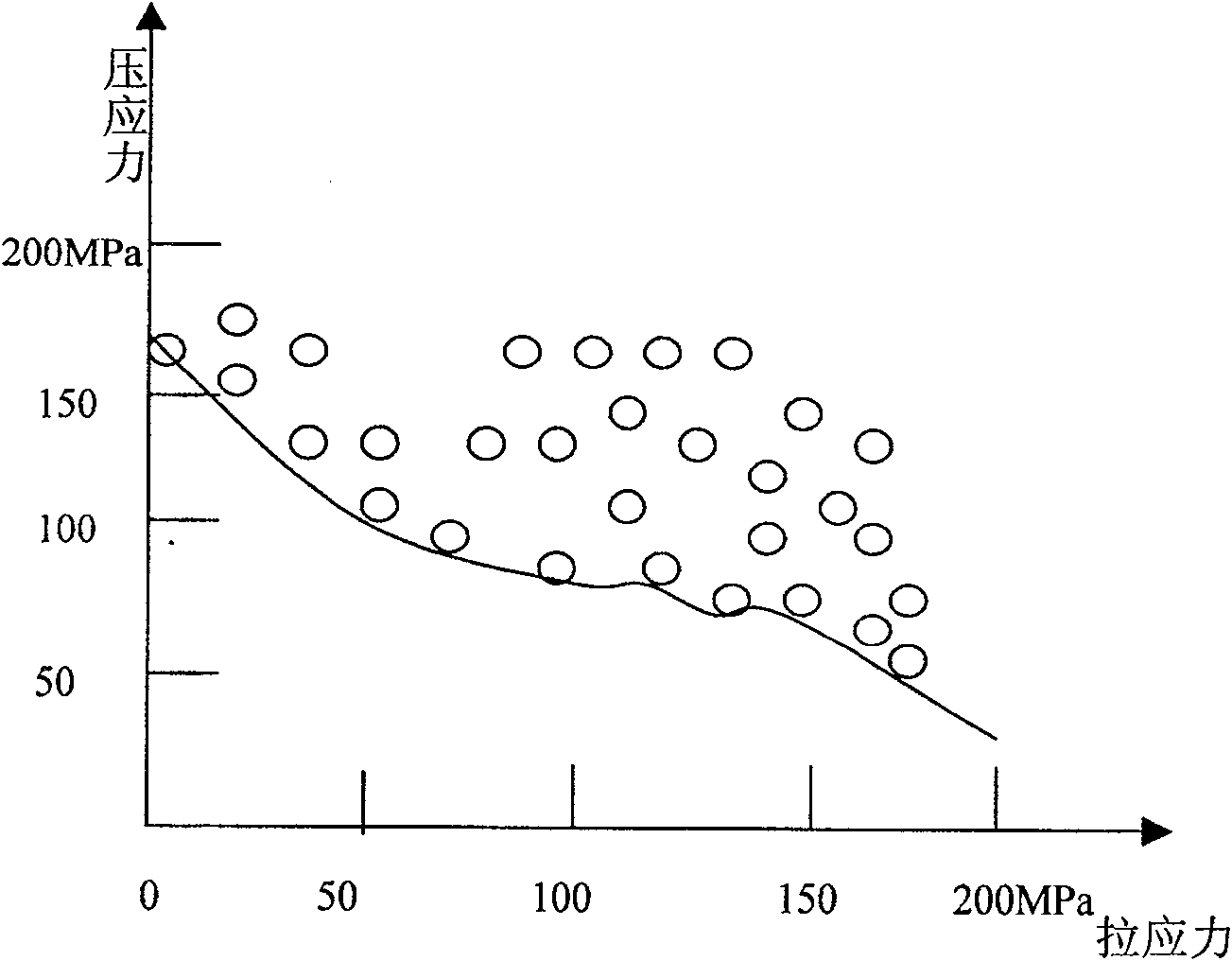

[0016] 4) After pressing, remove the tensile load, and record the tensile stress and vertical compressive stress at the coating failure point through the system microscopic imaging system;

[0017] 5) Repeat the above steps to obtain the tensile stress and vertical compressive stress data of the sample under the tensile fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com