Patents

Literature

42results about How to "Evaluation quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

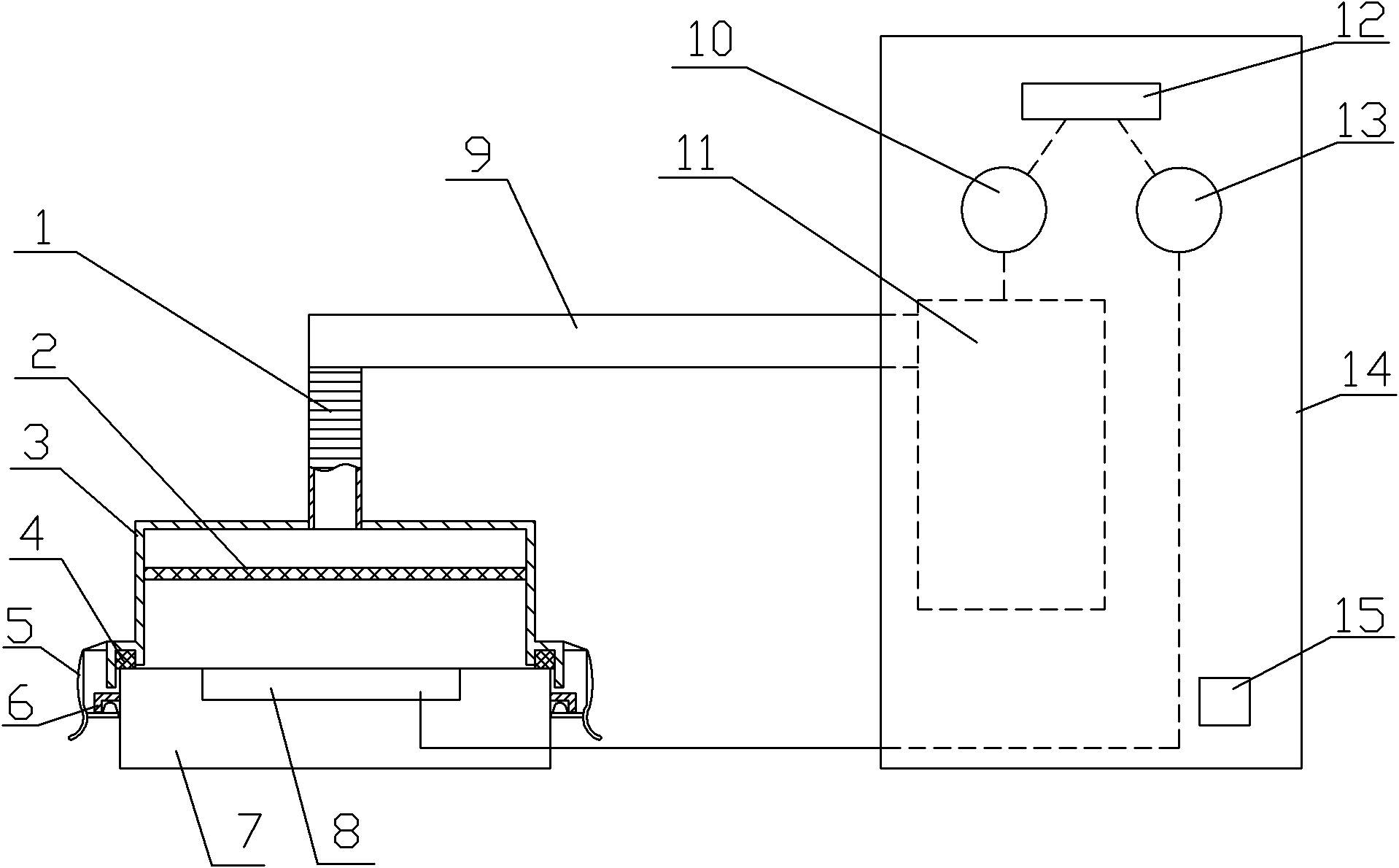

Full-performance detecting system of magnetic latching relay and detecting method thereof

ActiveCN102981120AWith alarm functionFunctionalMachine part testingCircuit interrupters testingResistive loadElectric power

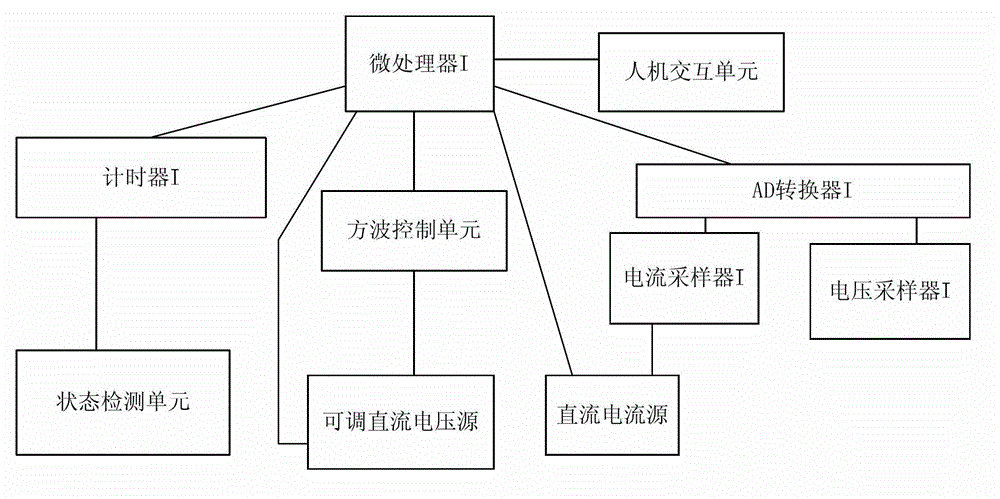

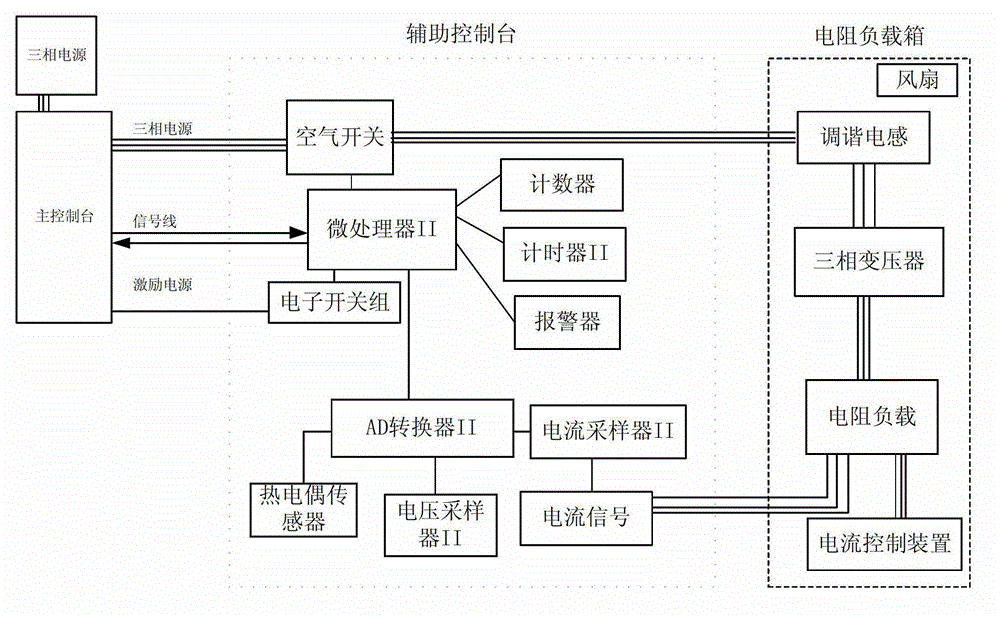

The invention relates to the field of electrical equipment detection, in particular to a full-performance detecting system of a magnetic latching relay and a detecting method of the full-performance detecting system of the magnetic latching relay. The detecting system comprises a main control panel, an auxiliary control panel and a resistive load box, wherein the auxiliary control panel is communicated with the main control panel through a network port, the auxiliary control panel controls the resistive load box to work by controlling an air switch, and the main control panel is connected with the magnetic latching relay. An ongoing full-performance test of the magnetic latching relay comprises an initial operation voltage, a returned value voltage test, an operation time test, a four probe method and high current method coil resistance test, a contact temperature-rise test, a mechanical life test, an electrical endurance test and an overload test. The full-performance detecting system is simple in wiring, capable of automatically finishing an electrical performance test, a safety performance test and a service life test without manual intervention, comprehensive in test items, and simple in test process.

Owner:CHINA ELECTRIC POWER RES INST +1

PM2.5 (Particulate Matter2.5) concentration detector based on definition evaluation without reference image

InactiveCN103954542AEvaluation ClaritySharpness comparisonParticle suspension analysisLaser rangingVisibility

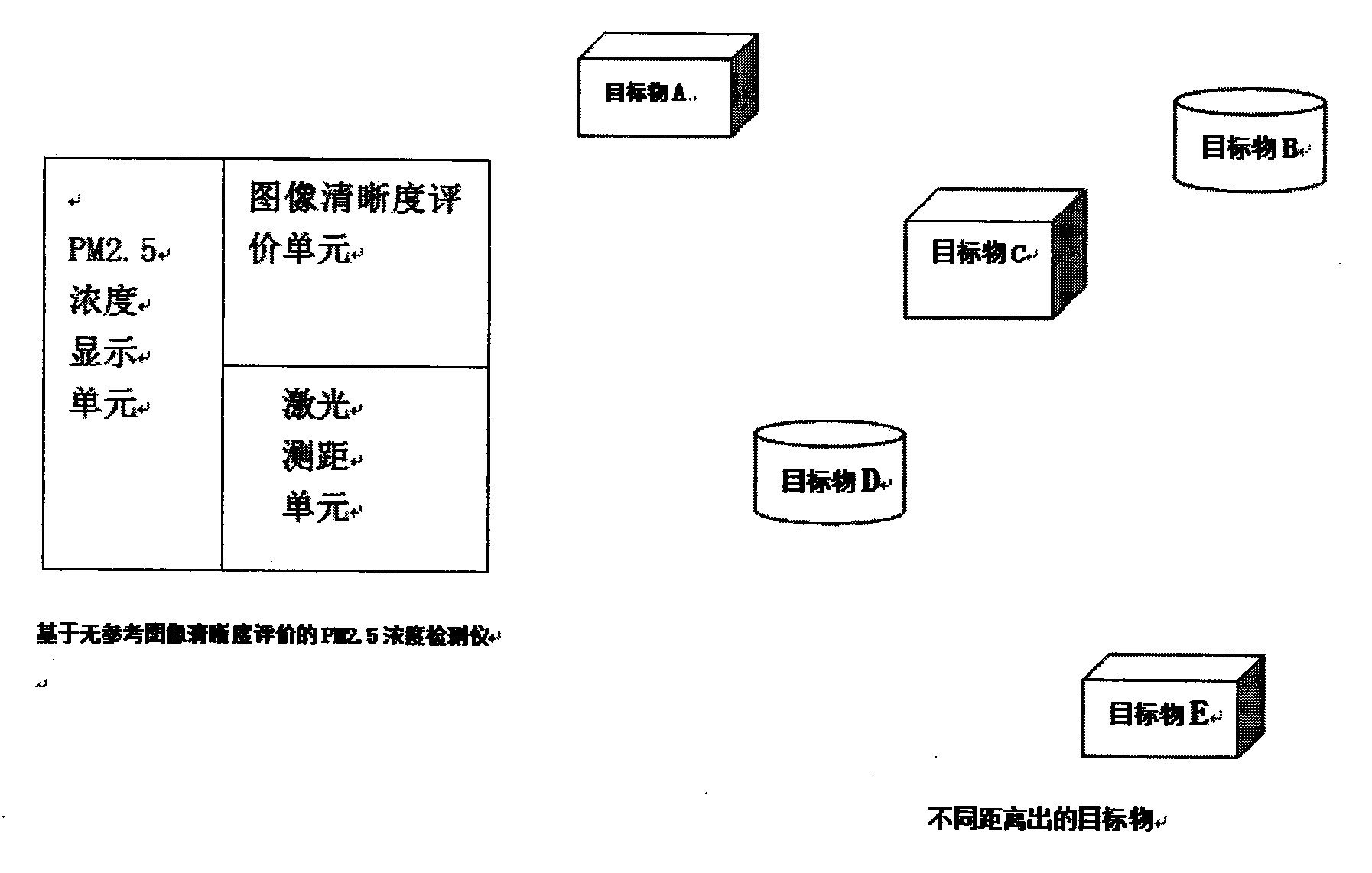

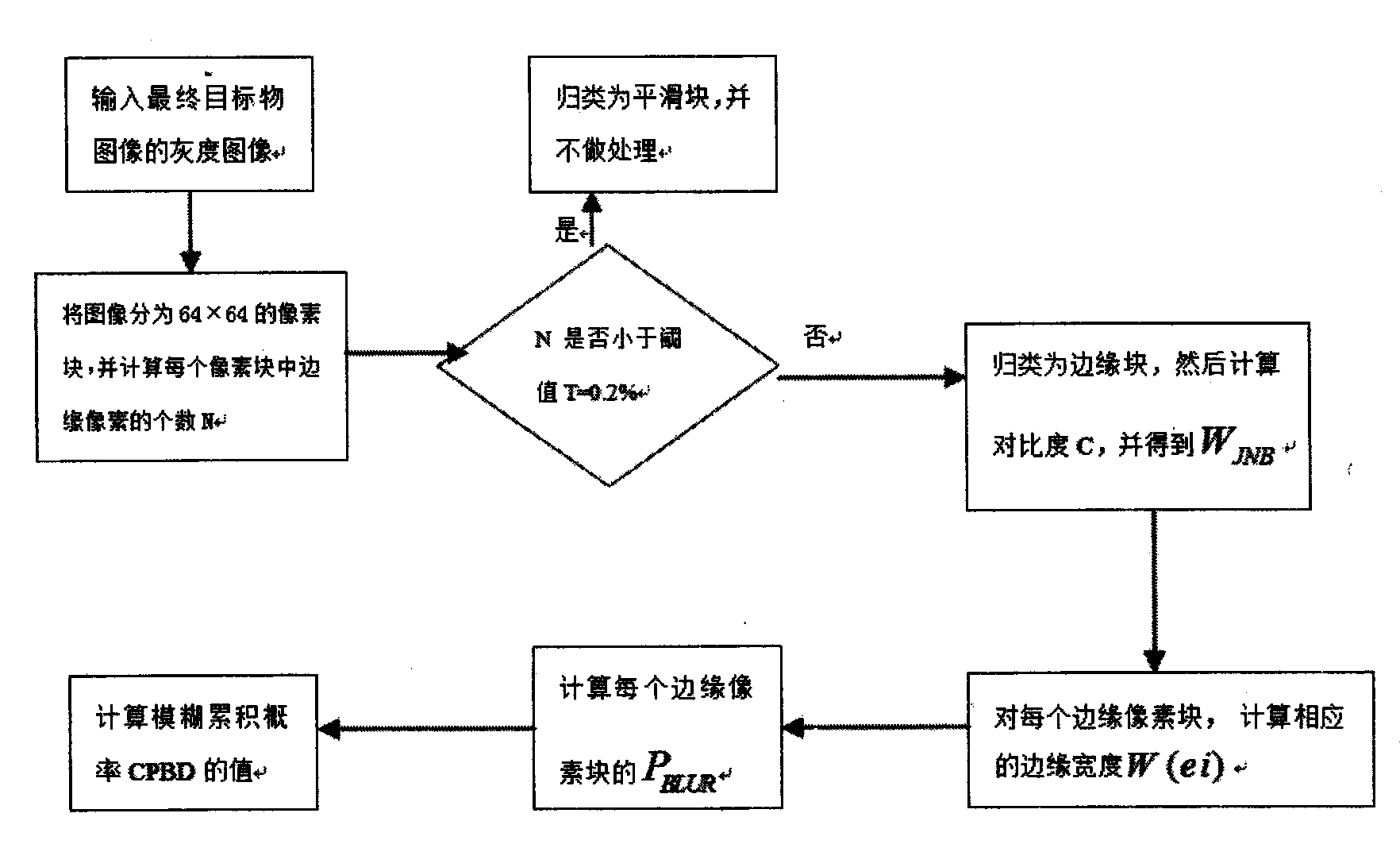

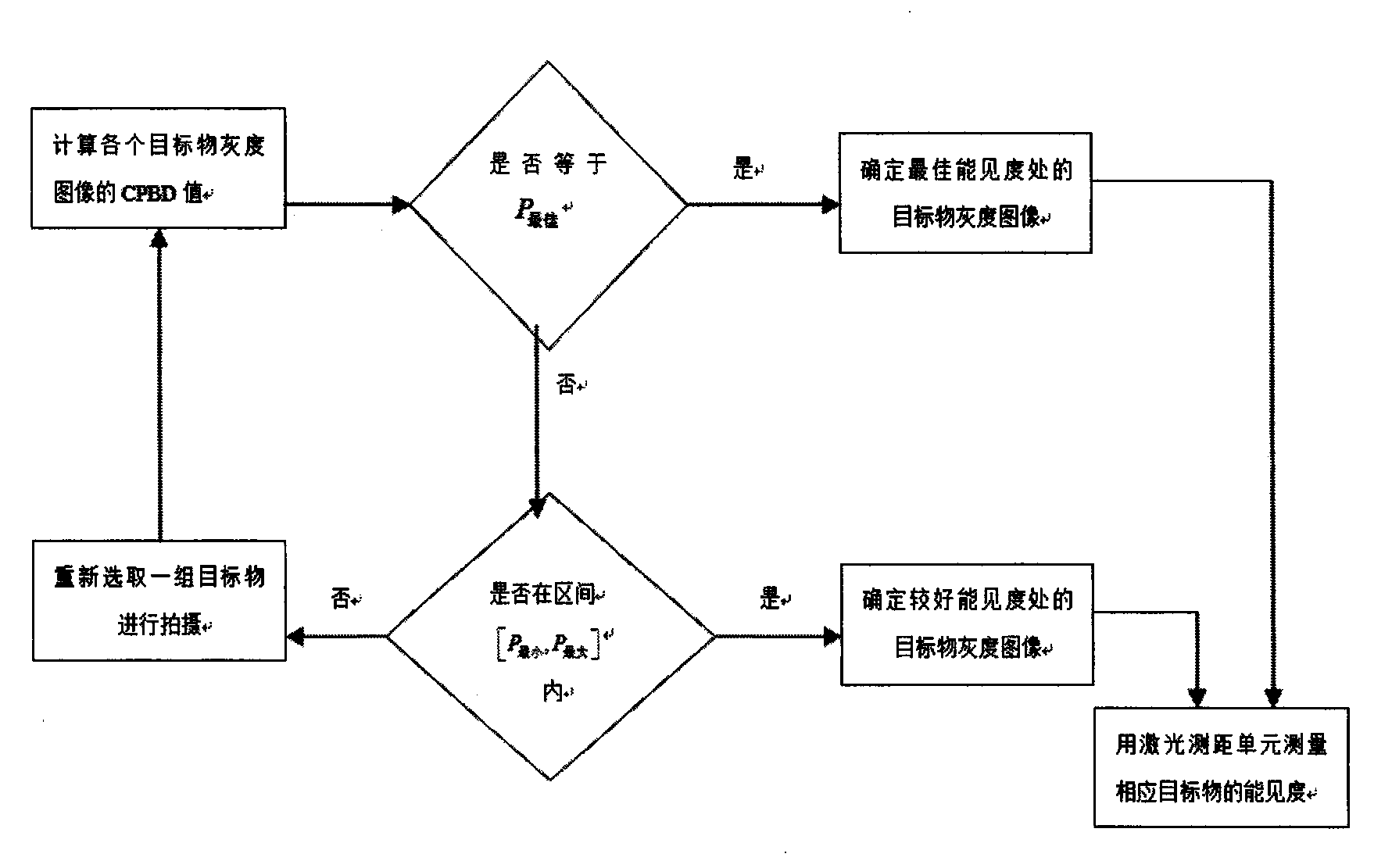

The invention relates to a PM2.5 (Particulate Matter2.5) concentration detector based on definition evaluation without a reference image. The PM2.5 concentration detector mainly comprises an image definition evaluation unit, a laser ranging unit and a PM2.5 concentration display unit, wherein the image definition evaluation unit works as follows: images of target objects in different distances are shot by a camera, the images are converted into grayscale images, the grayscale images are segmented into 64*64 pixel blocks by adopting a no-reference-image definition evaluation method, the 64*64 pixel blocks are compared with the preset threshold value T equal to 0.2%, the edge blur detection probability P(BLUR) of the segmented edge pixel blocks is calculated, then the fuzzy cumulative probability CPBD value of the whole grayscale images is calculated, the fuzzy cumulative probability CPBD value is compared with the interval (minimum P-maximum P) of the CPBD threshold value P of the optimal visibility image and the CPBD value of the better image, and the target object to be detected is determined; the laser ranging unit is used for measuring the distance of the target object to be detected and determining the visibility distance value; the PM2.5 concentration display unit is used for calculating and displaying the PM2.5 concentration according to the relations of the scattering coefficient and the visibility as well as the scattering coefficient and the PM2.5 concentration.

Owner:CHINA JILIANG UNIV

Visual real-time monitoring system and method for vibration quality of normal state concrete

InactiveCN106707932AUninterrupted visualizationEasy to installProgramme controlComputer controlInfraredVibration control

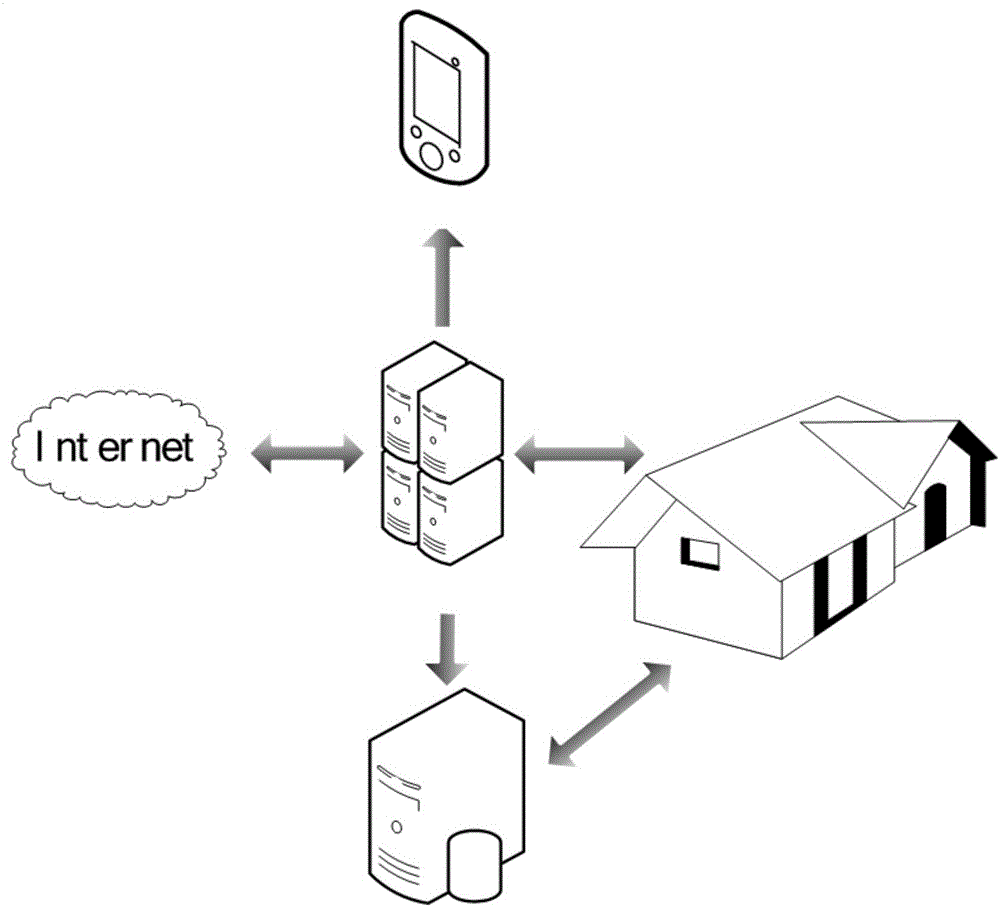

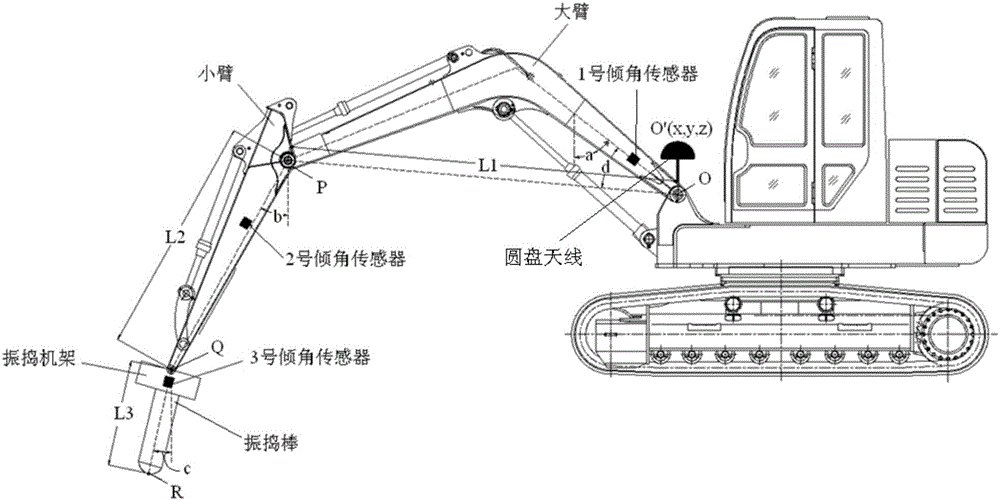

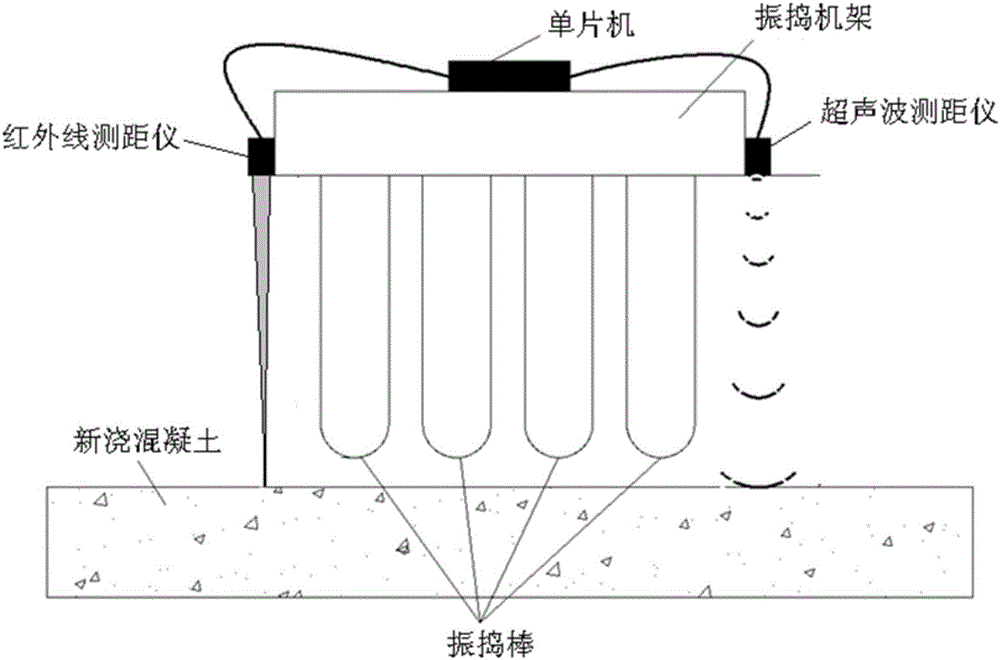

The invention discloses a visual real-time monitoring system and method for the vibration quality of normal state concrete, and the system comprises GPS positioning equipment, an inclination angle sensor, an electronic compass, a vibration switch state sensor, an ultrasonic ranging sensor, an infrared ranging sensor, a single-chip microcomputer, wireless network transmission equipment, alarm equipment, an application server, a database server and a monitoring client, wherein the GPS positioning equipment, the inclination angle sensor, the electronic compass, the vibration switch state sensor, the ultrasonic ranging sensor, the infrared ranging sensor, the single-chip microcomputer, the wireless network transmission equipment, the alarm equipment, the application server, the database server and the monitoring client are disposed on a vibration machine. A vibration rack is provided with a vibration rod. The inclination angle sensor is used for measuring the inclination angles of a big arm, a small arm and the vibration rack. In a construction process, the system can display a qualified vibration region, an excessive vibration region, an under-vibration region and a vibration leakage region of a warehouse surface at a monitoring terminal through graphs with different colors. If the proportion of the excessive vibration region to the under-vibration region exceeds a specified standard, the system will give an alarm in real time, and transmits the alarm information, thereby bringing convenience to a worker and a supervisor on a construction site to adjust the construction scheme timely according to the conditions, and guaranteeing the concrete vibration quality.

Owner:TIANJIN UNIV

Method for determining quality of coat

InactiveCN101004373AEvaluation qualityUsing mechanical meansStrength propertiesMicro imagingCoated surface

A method for judging quality of coated layer includes carrying out conventional single-direction of tensile or compression plasticity deformation test on test-piece by tester, holding load to measure section area of test-piece when tensile or compression is on certain degree, using impression tester to make multipoint vertical pressure stress load on coated layer surface at parallel section on test-piece under condition of load-holding, releasing all loads off and using micro-imaging unit to judge out destroying point of tensile or compression stress and vertical pressure stress on coated layer.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

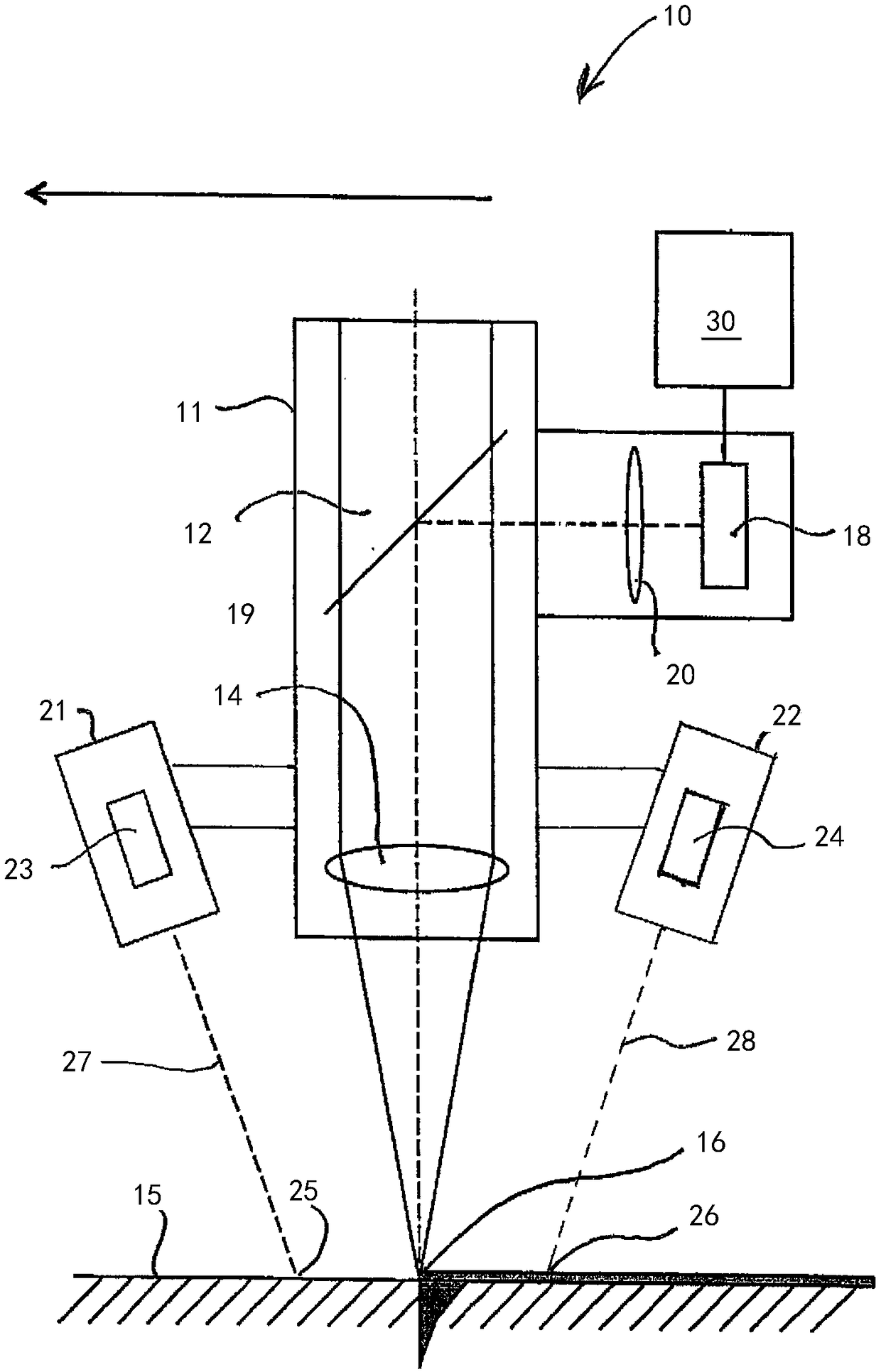

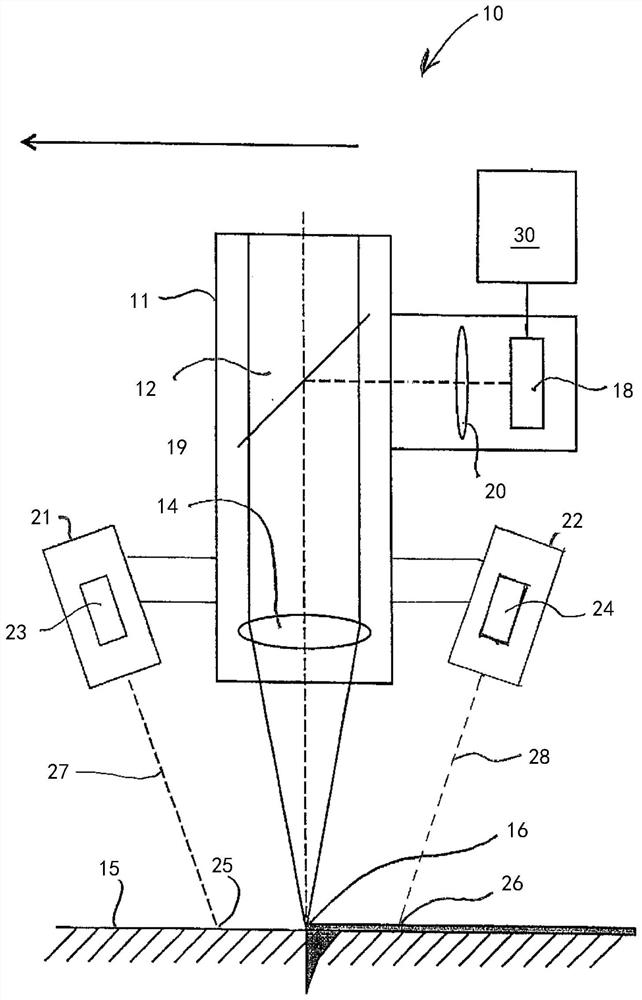

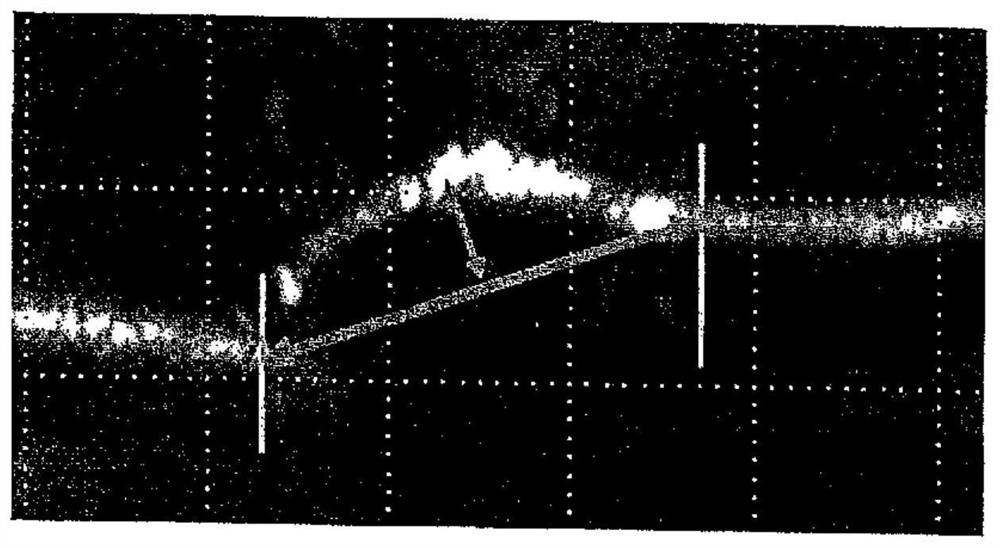

Method and device for monitoring a joining seam during joining by means of a laser beam

ActiveCN108883495AEvaluation qualityArc welding apparatusLaser beam welding apparatusLaser processingEngineering

The invention relates to a method for monitoring a joining seam, in particular during joining by means of laser radiation, wherein in the processing direction before a processing point, a joining siteis measured in order to detect the position and geometry thereof, at least one position of a joining seam is determined after the processing point from the position of the joining point before the processing point, and in the processing direction after the processing point, the joining seam is measured in order to detect the geometry thereof at the determined position. The invention further relates to a device for carrying out said method and to a laser processing head equipped with such a device.

Owner:PRECITEC GMBH

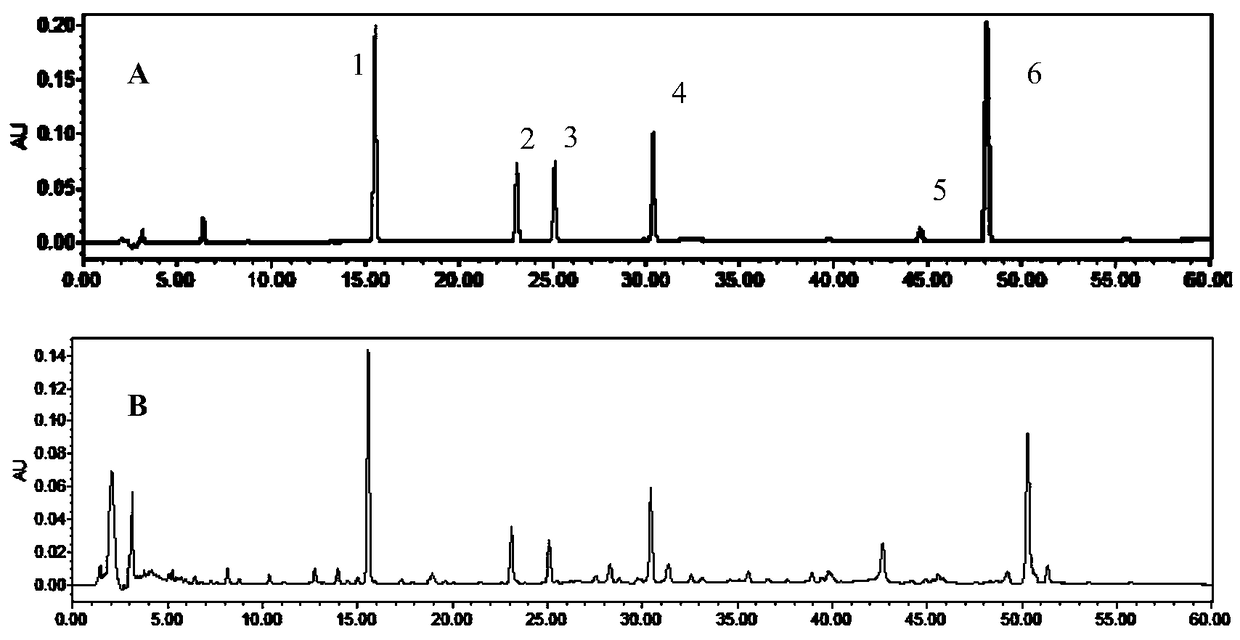

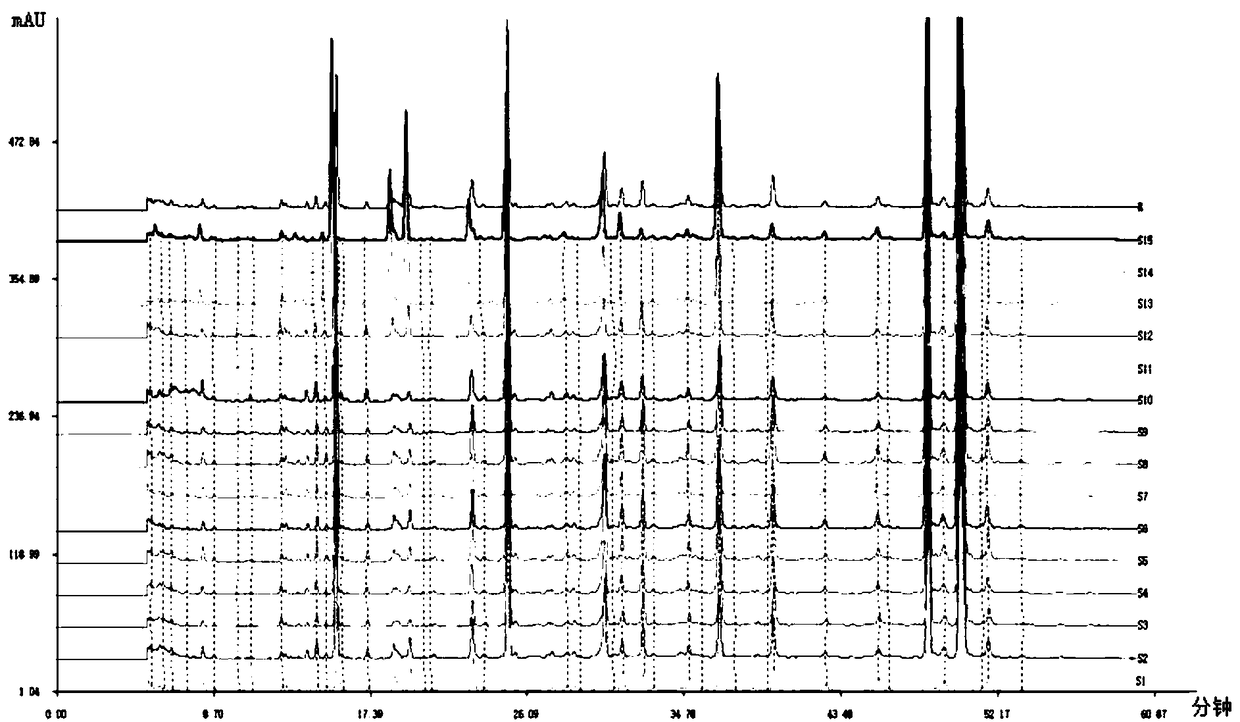

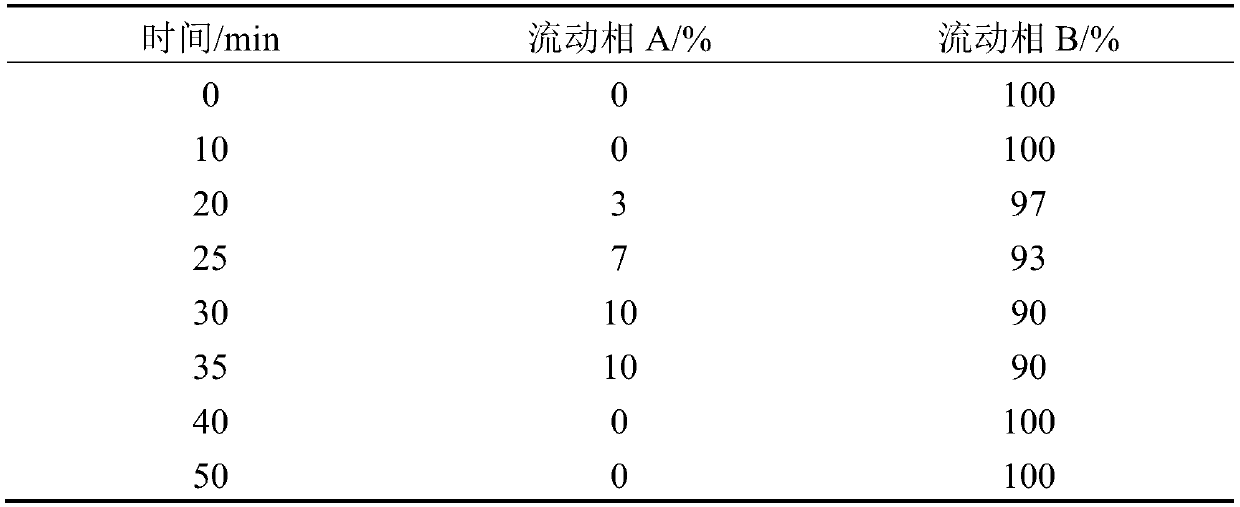

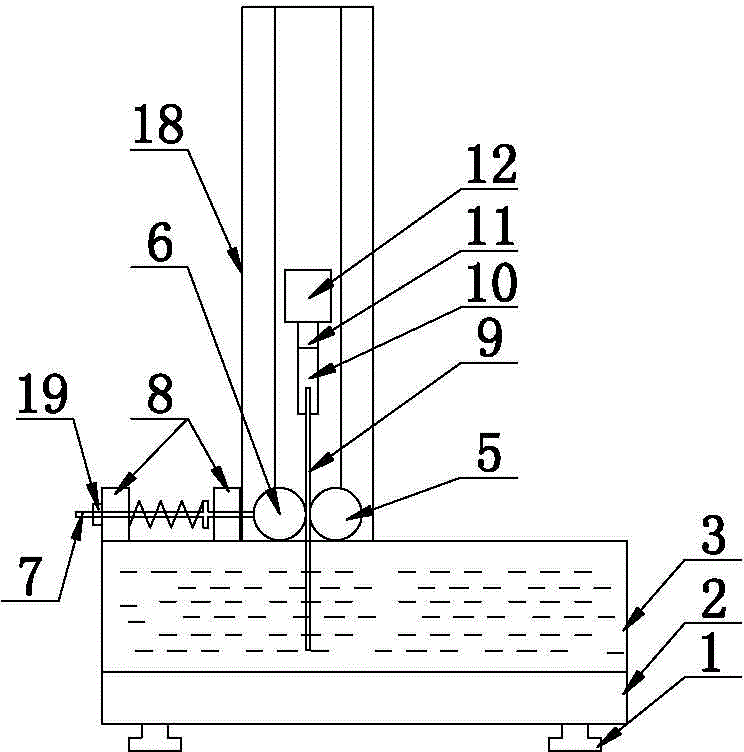

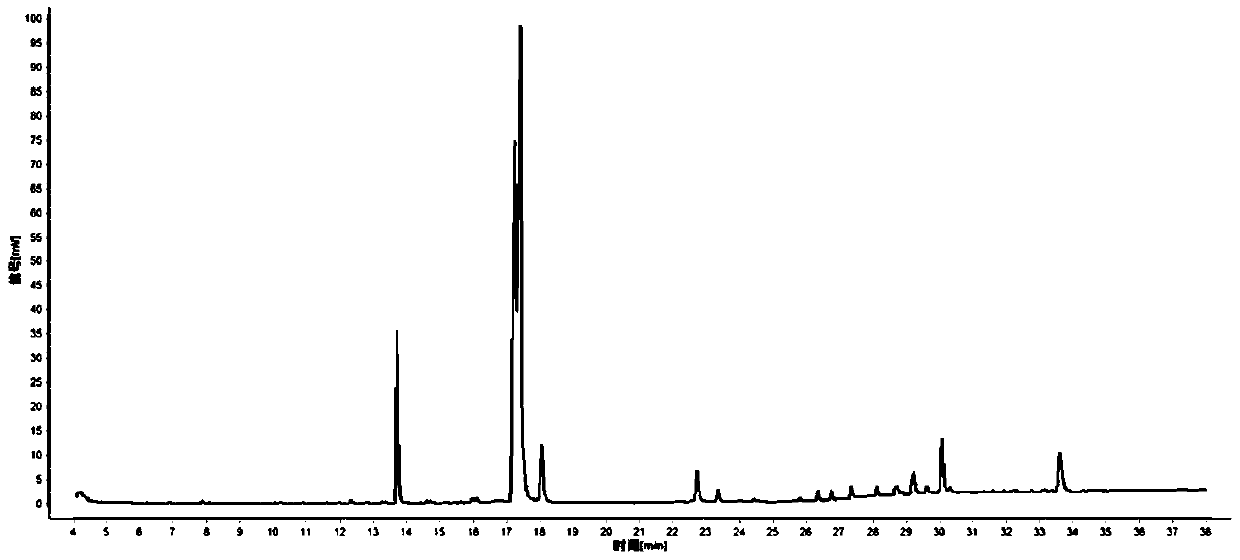

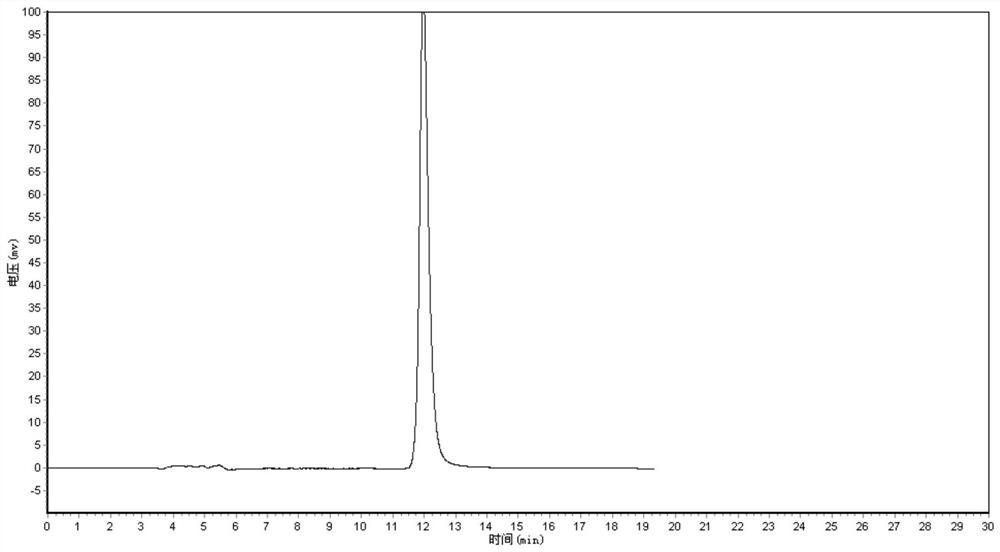

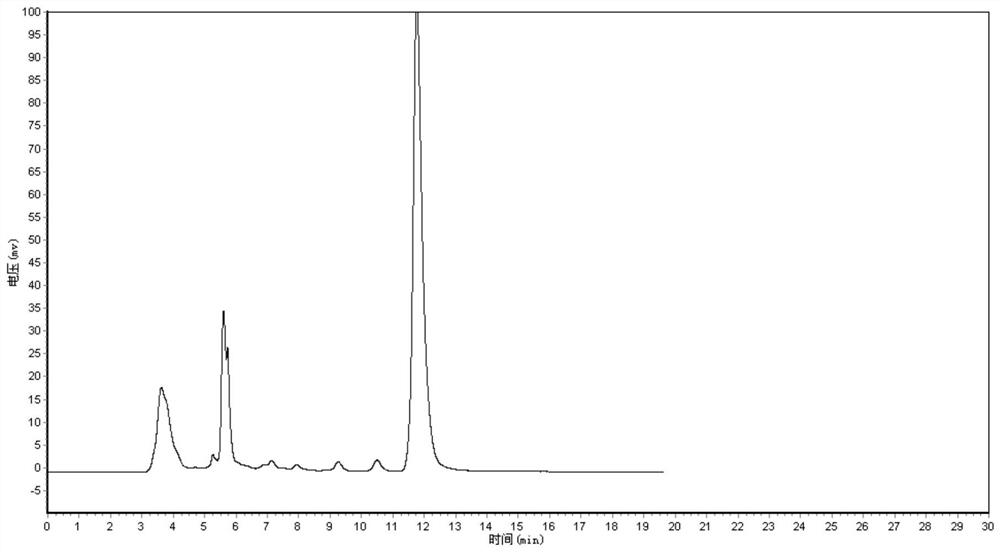

Quality control method for dried ginger

The invention discloses a quality control method for dried ginger. The method comprises the following steps of: determining the content of 4 ginger phenolic chemical components including 6-gingerol, 8-gingerol, 6-shogaol and 10 gingerol, and 2 volatile oil chemical components including alpha-curcumene and (E)-beta-farnesene in the dried ginger medicinal materials by adopting an HPLC-PDA method; and taking the total amount of the ginger phenolic components, the total amount of the volatile oil components, or the total amount of the ginger phenolic components and the volatile oil components as an evaluation index, which is used for formulating a standard for evaluating the quality of the dried ginger medicinal material and controlling the quality. The method is capable of comprehensively, objectively and effectively evaluating the quality of the dried ginger medicinal material by simultaneously detecting two types of the active ingredients of the dried ginger medicinal material and analyzing the fingerprint spectrum and comparing with a single analysis of one or a class of chemical components, and is used for the quality control thereof, and the method is simple and convenient to operate, good in stability and easy to be popularized.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

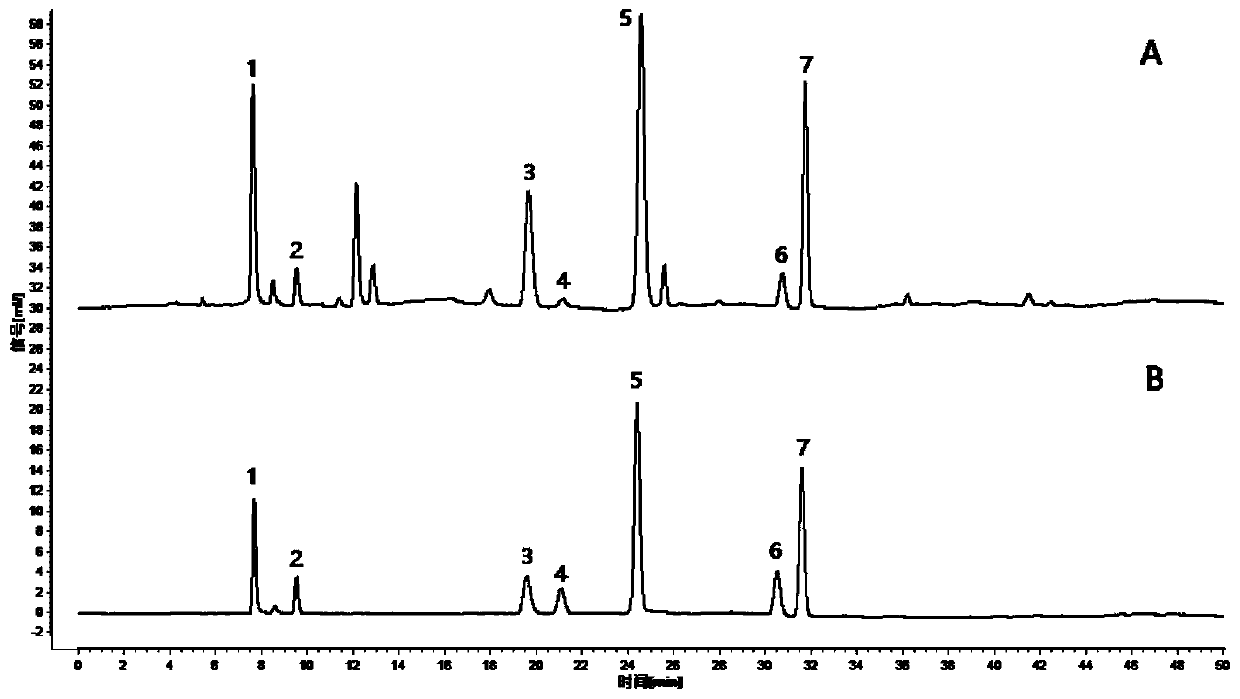

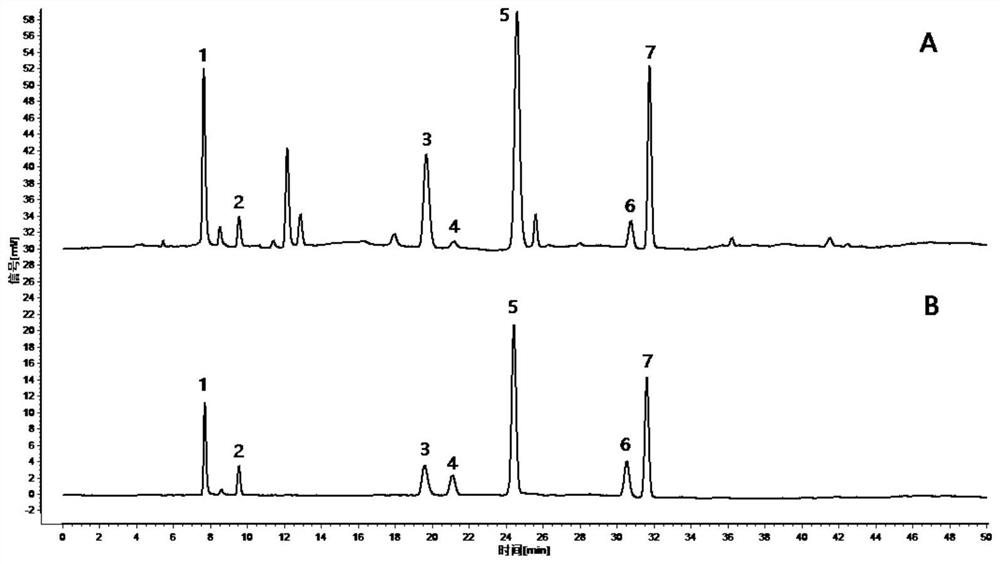

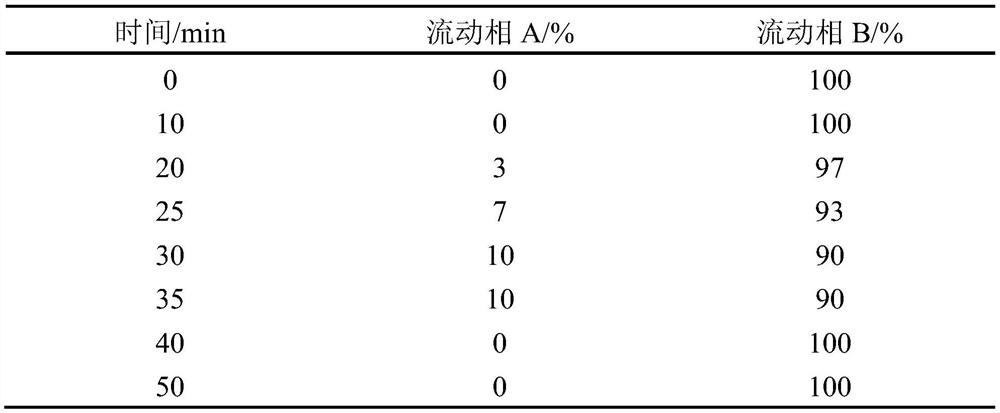

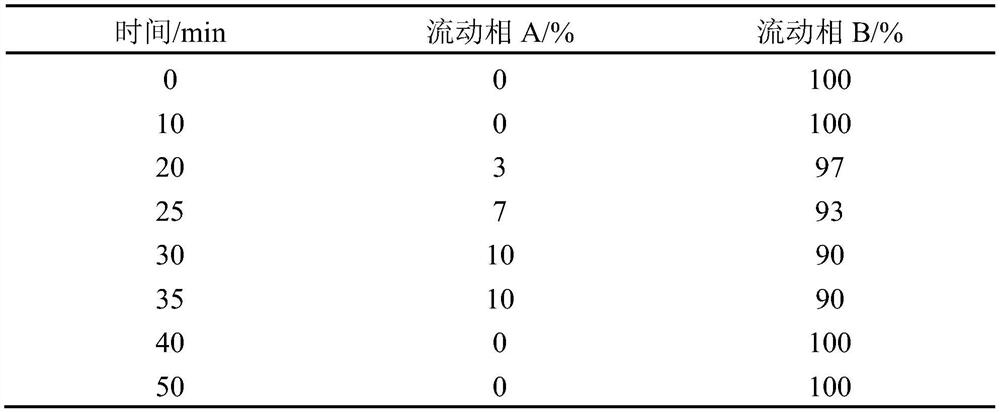

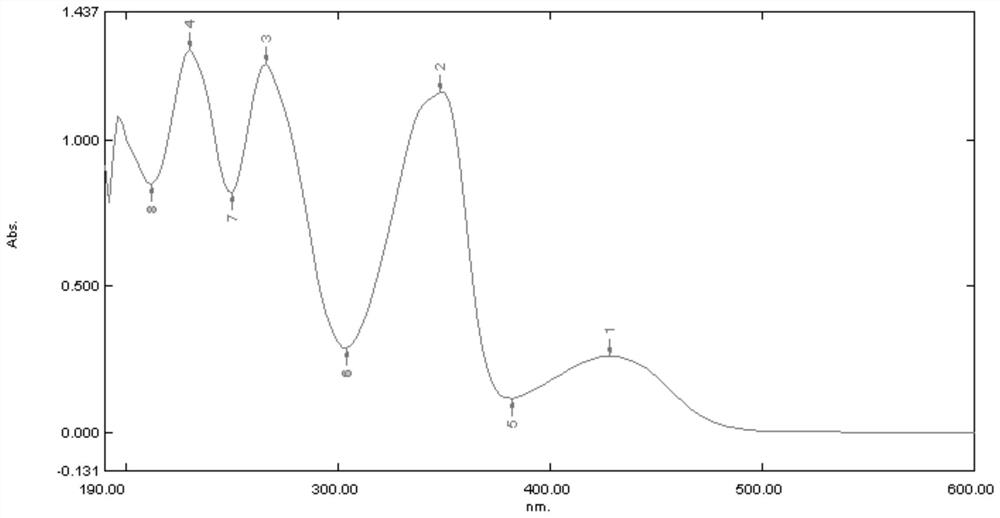

HPLC method for simultaneously measuring seven kinds of organic acids in pinellia ternata

ActiveCN110243970AEvaluate quality effectivelyEvaluation qualityComponent separationChemistryOrganic acid

The invention provides an HPLC method for simultaneously measuring four kinds of organic acids (oxalic acid, L-malic acid, citric acid and fumaric acid) in pinellia ternate. The method also can simultaneously measure another three kinds of organic acids (succinic acid, cis-aconitic acid and trans-aconitic acid). The pinellia ternate HPLC detection method in the invention can simultaneously measure multiple organic acid compositions in pinellia ternate medicinal materials, has the advantages of being simple to operate, high in sensitivity, good in specificity and high in accuracy, and can effectively evaluate the quality of the pinellia ternate medicinal materials.

Owner:CHENGDU UNIV OF TRADITIONAL CHINESE MEDICINE

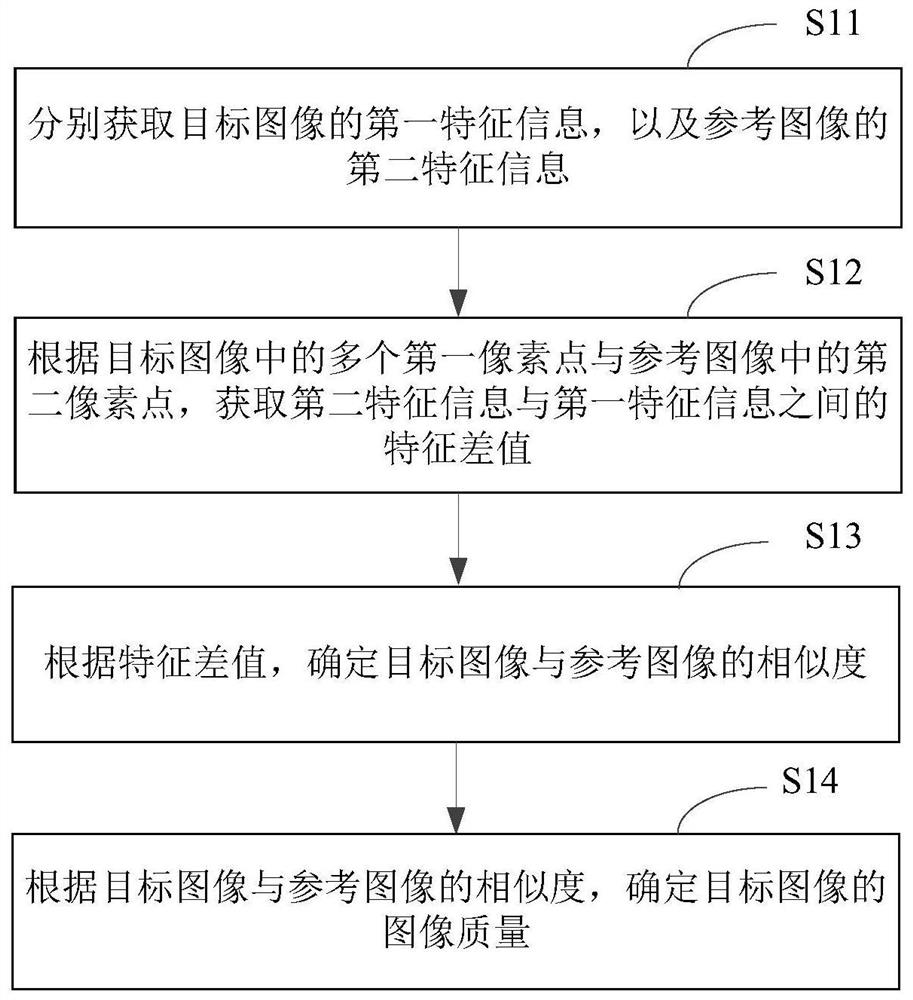

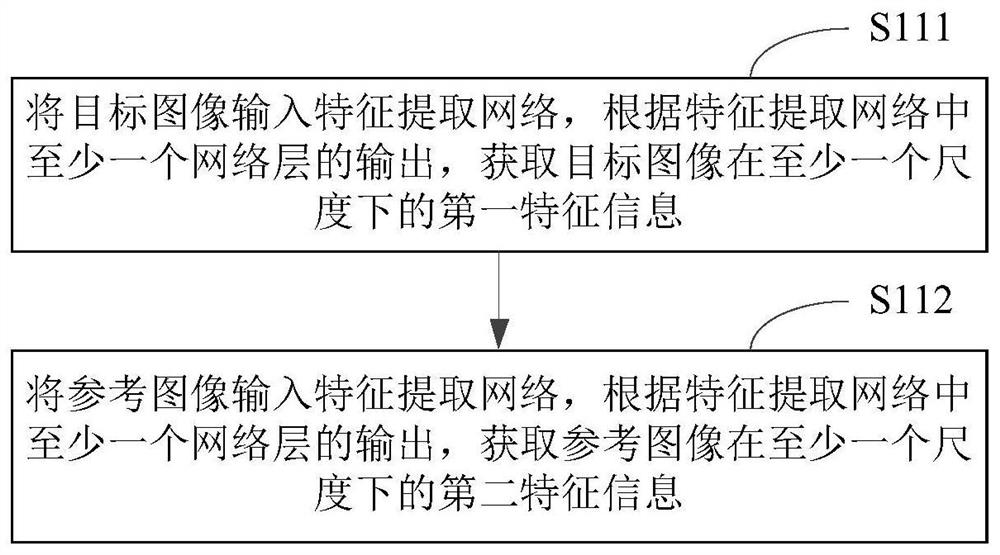

Image processing method and device, electronic equipment and storage medium

PendingCN112529846AAccurate and objective qualityImprove accuracyImage enhancementImage analysisImaging processingImaging quality

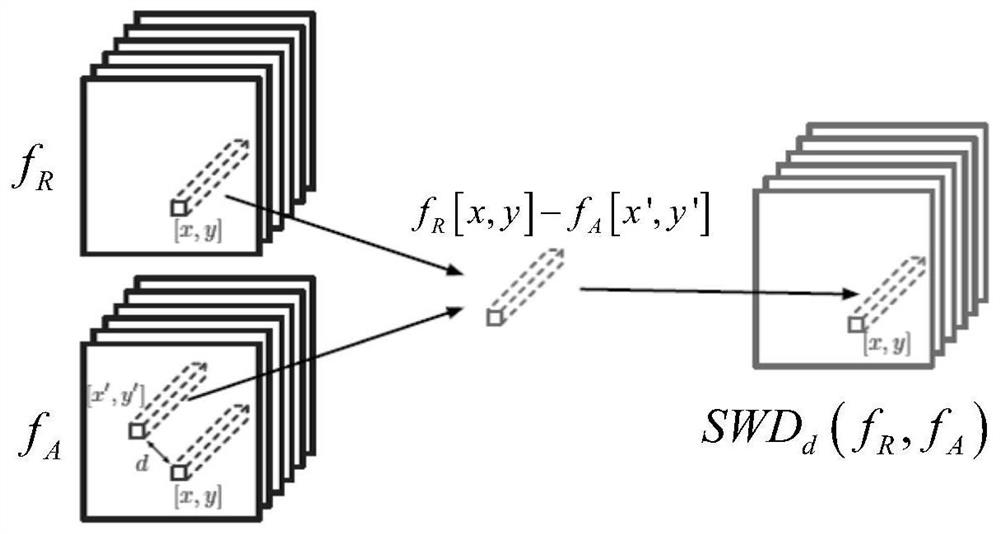

The invention relates to an image processing method and device, electronic equipment and a storage medium. The method comprises the steps: acquiring first feature information of a target image and second feature information of a reference image respectively, wherein the target image and the reference image correspond to the same scene; according to a plurality of first pixel points in the target image and a second pixel point in the reference image, obtaining a feature difference value between the second feature information and the first feature information, wherein the distance between the plurality of first pixel points and the second pixel point in space does not exceed a preset range; determining the similarity between the target image and the reference image according to the feature difference value; and determining the image quality of the target image according to the similarity between the target image and the reference image.

Owner:SHENZHEN SENSETIME TECH CO LTD

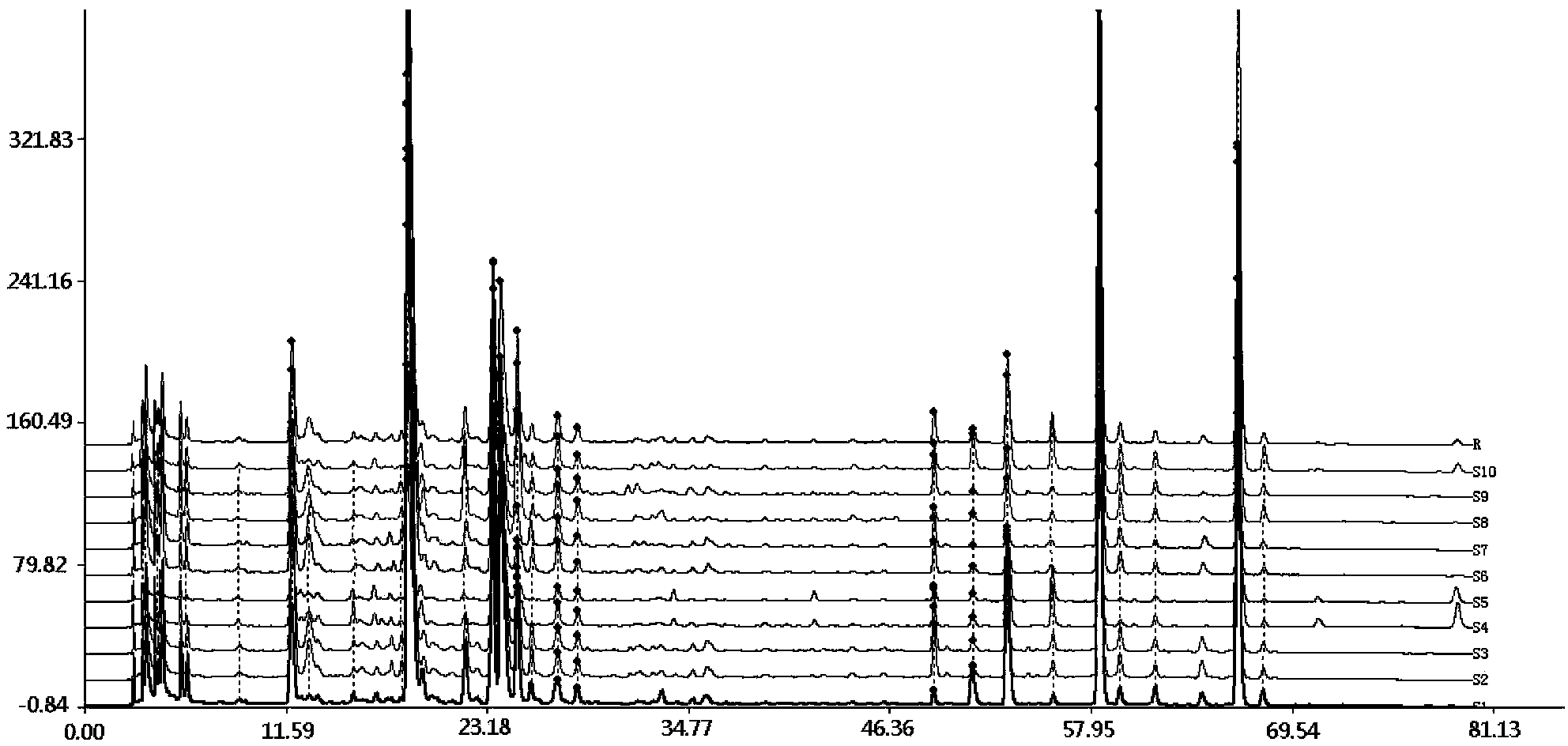

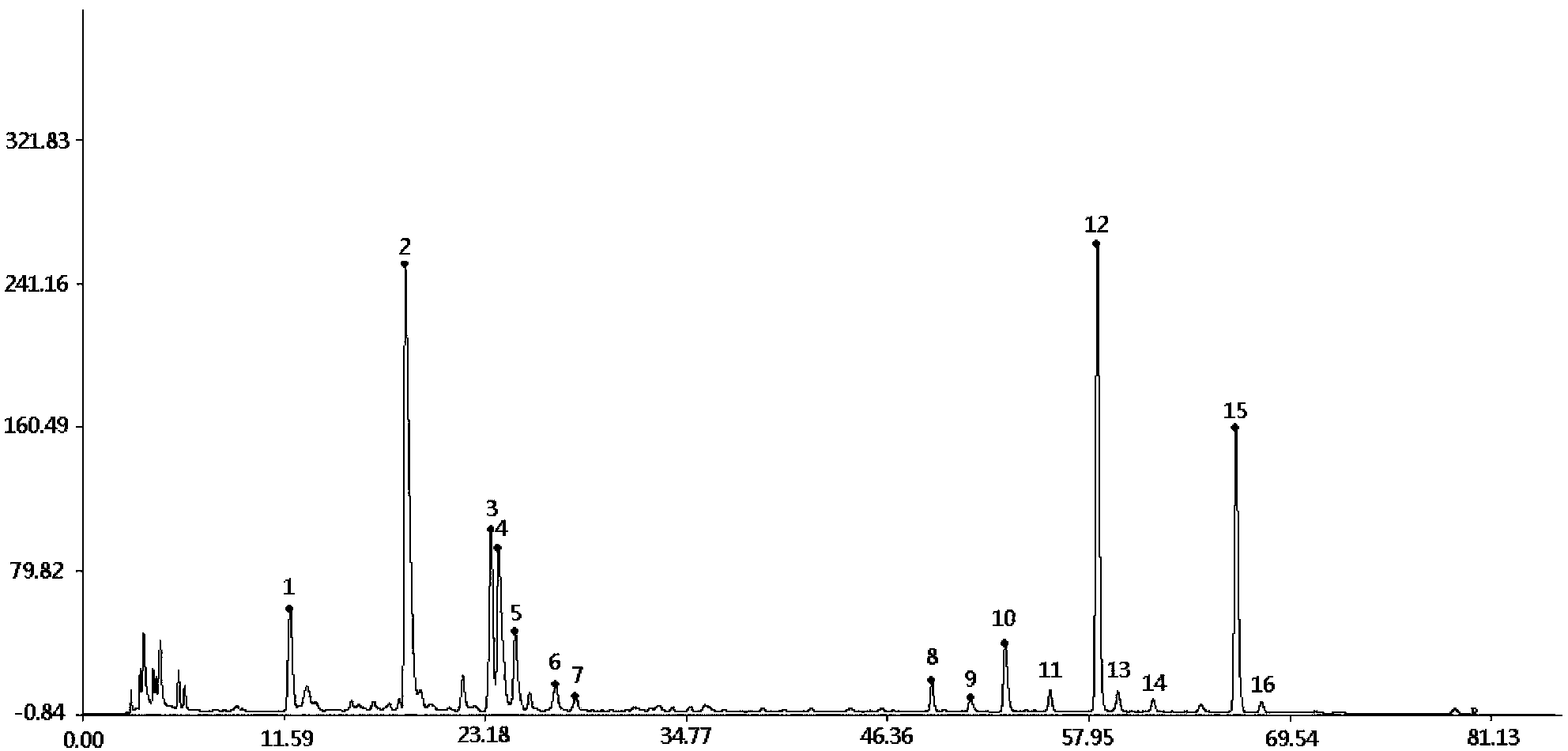

Method for analyzing active component in harmel grass

The invention discloses a method for analyzing an active component in harmel grass. The method comprises the following steps of: constructing a finger print, analyzing the active component in a qualitative manner through the finger print, detecting the content of the active component through an HPLC (high performance liquid chromatography) method, wherein the finger print comprises a TLC (thin-layer chromatography) finger print and / or HPLC finger print. According to the invention, the constructed finger print has excellent reproducibility and specificity, and has good stability, precision and application sample recovery ratio on the content detection method of the active component, can realize qualitative and quantitative analysis of various active components such as vasicine, peganine, harmine, deacetylation harmel glycoside and harmel glycoside in the harmel grass, can fully evaluate the quality of the harmel grass, and can provide scientific reference for medicinal value of research and development on harmel grass; and the analyzing method provided by the invention has the advantages of simplicity in operation, velocity, economy, strong operability and the like, and can carry out popularization and application.

Owner:SHANGHAI UNIV OF T C M

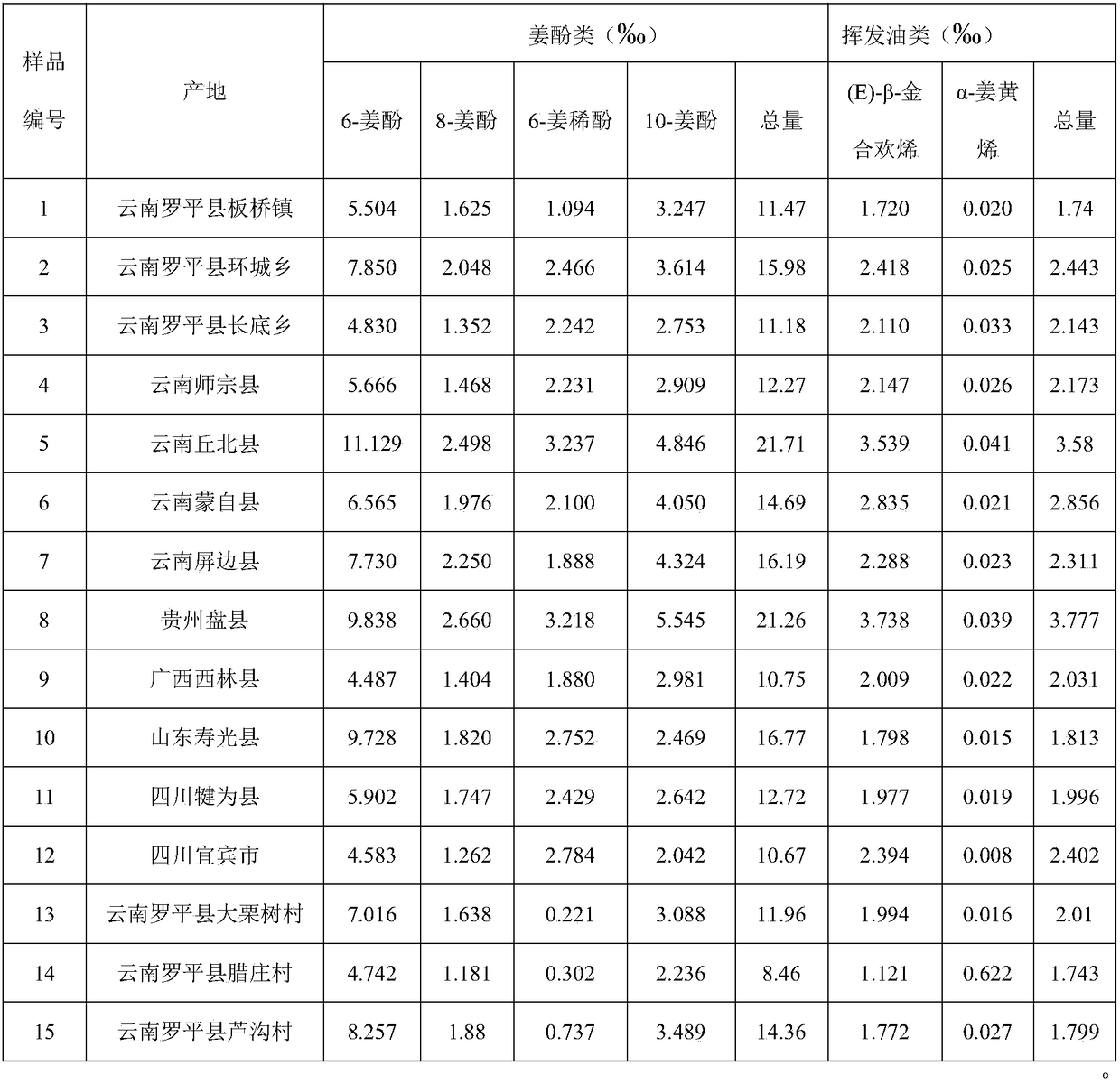

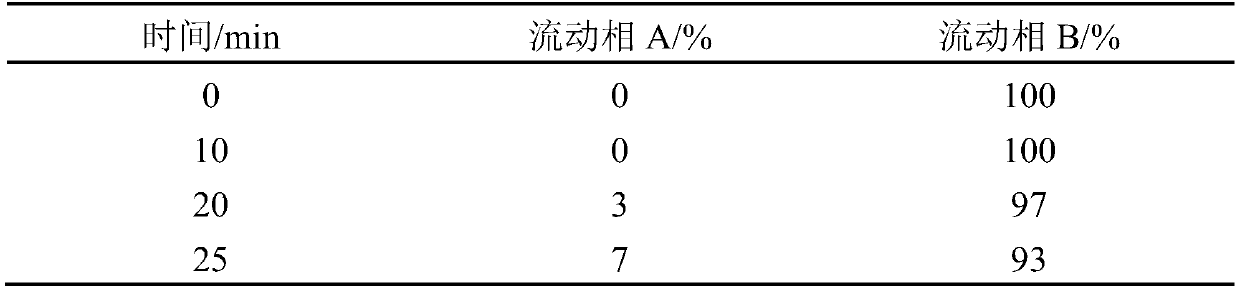

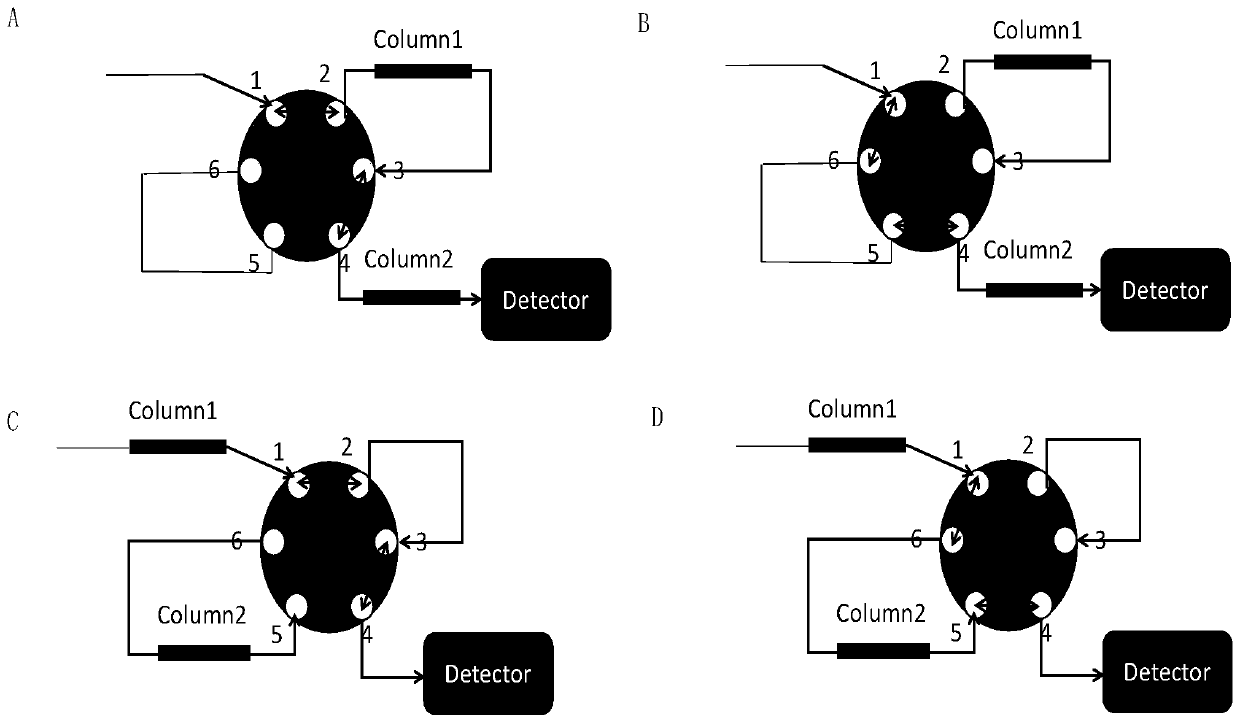

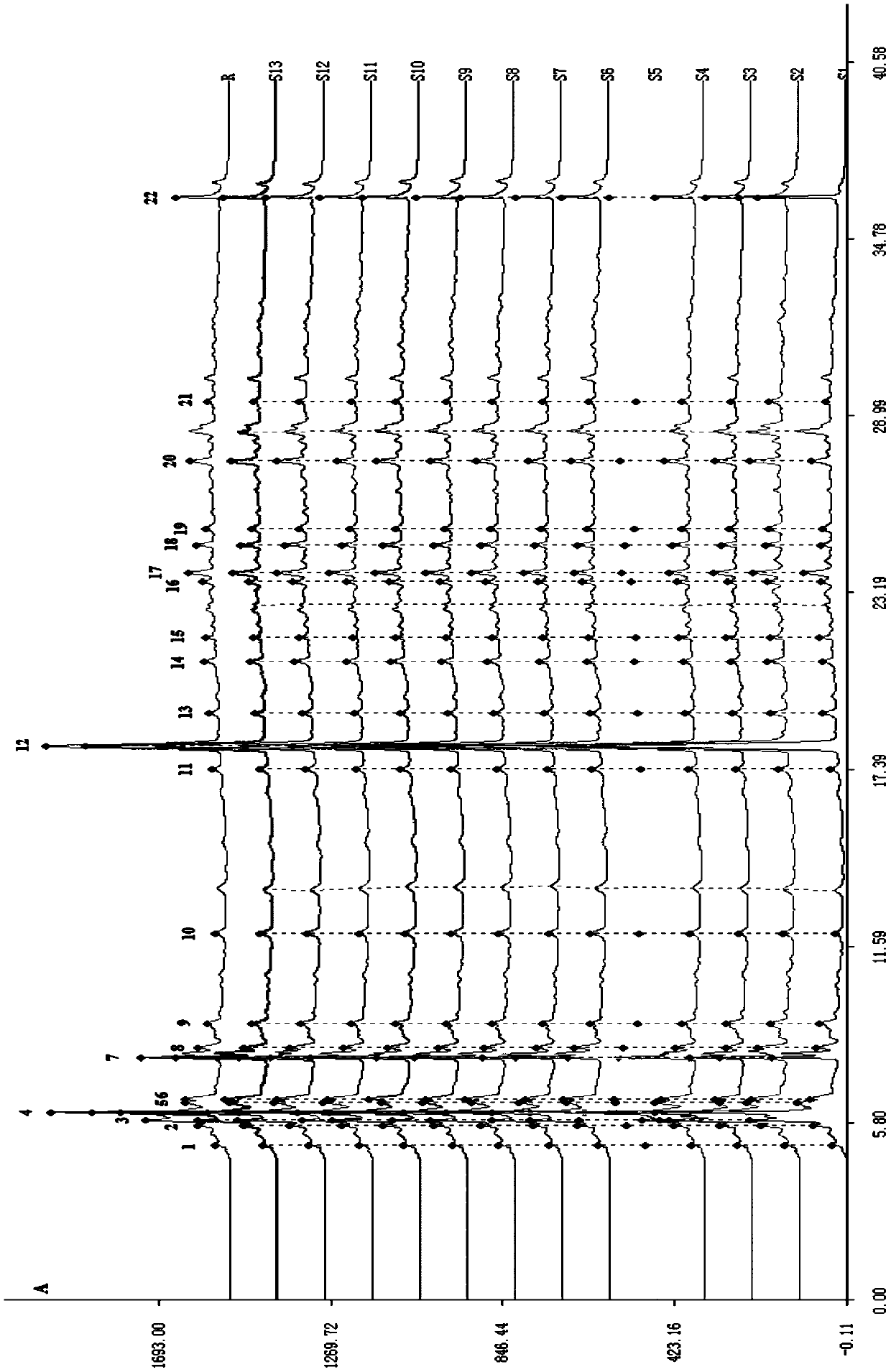

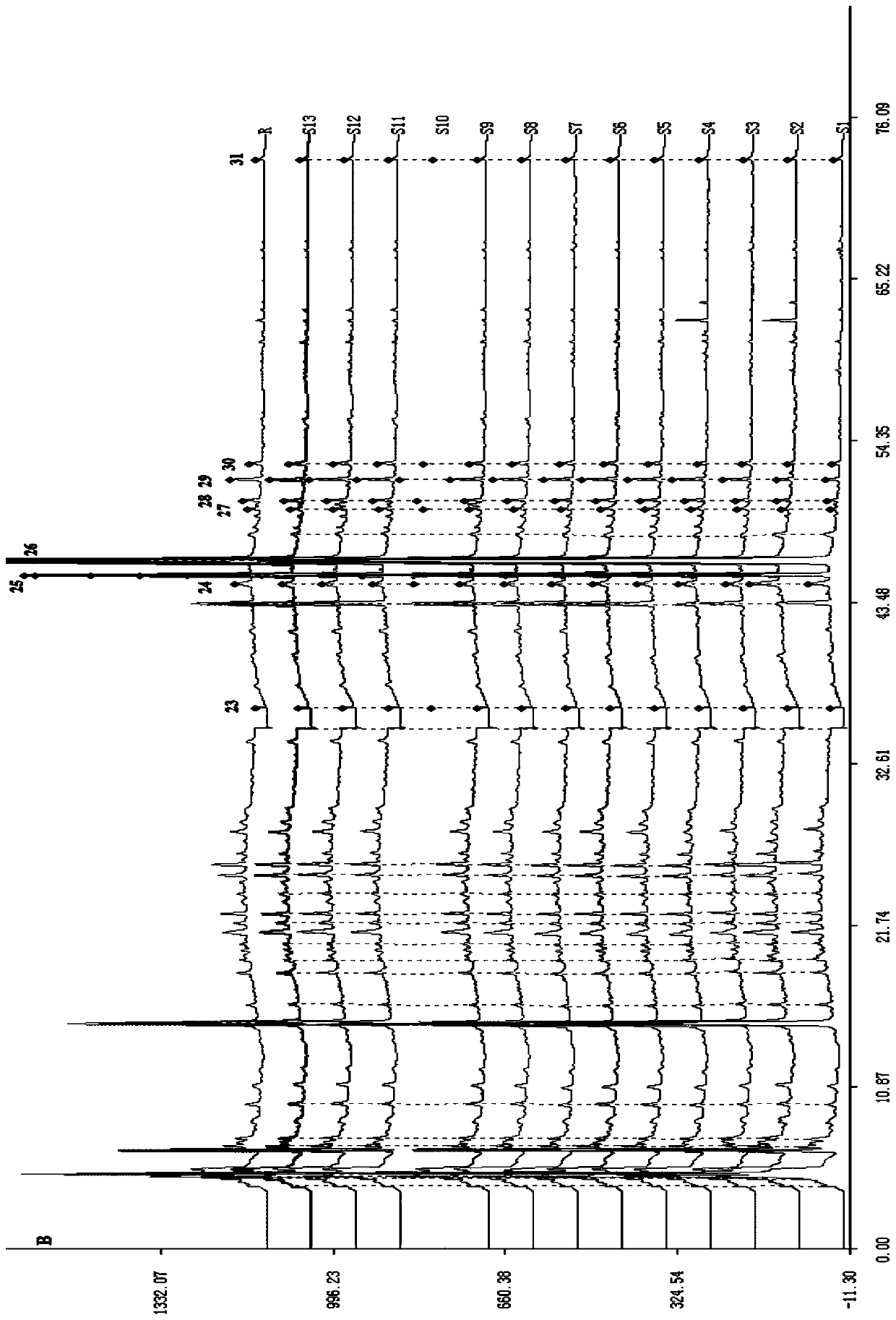

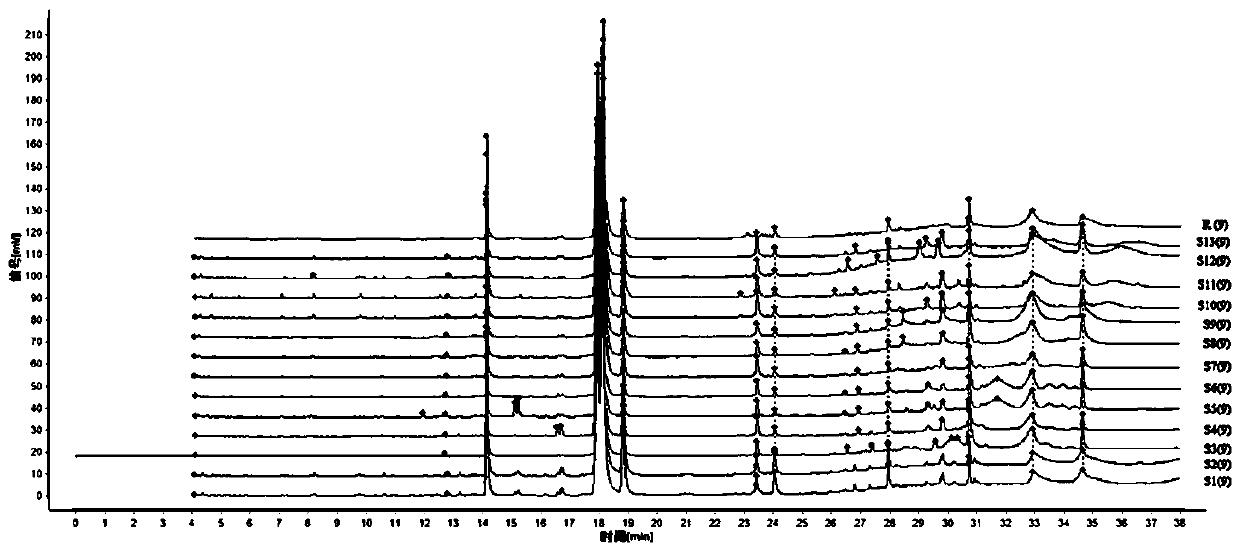

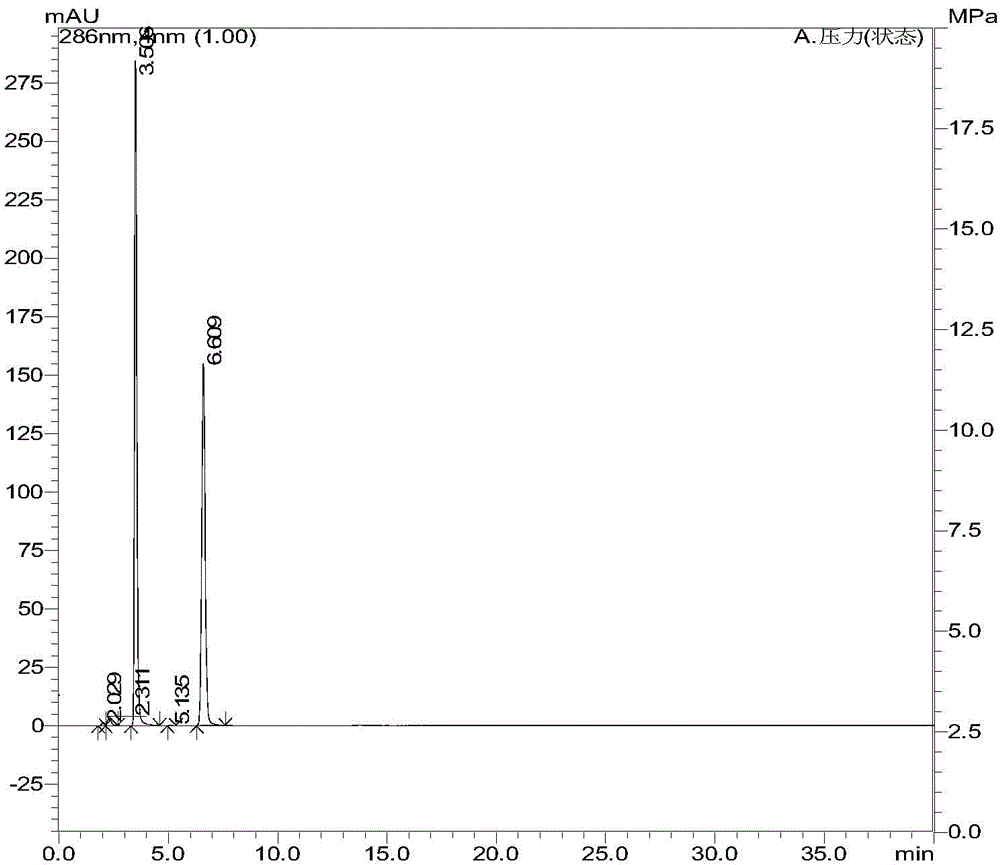

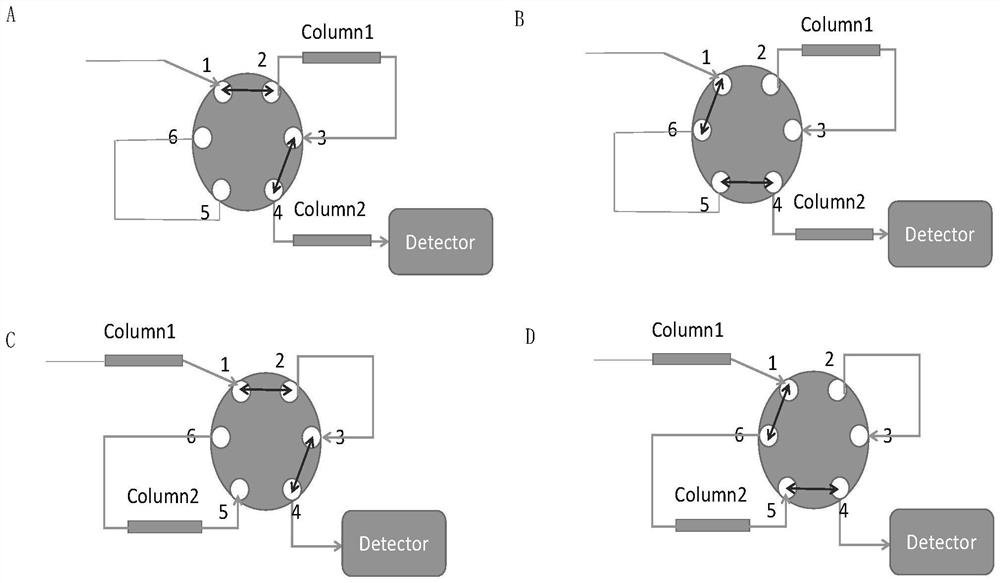

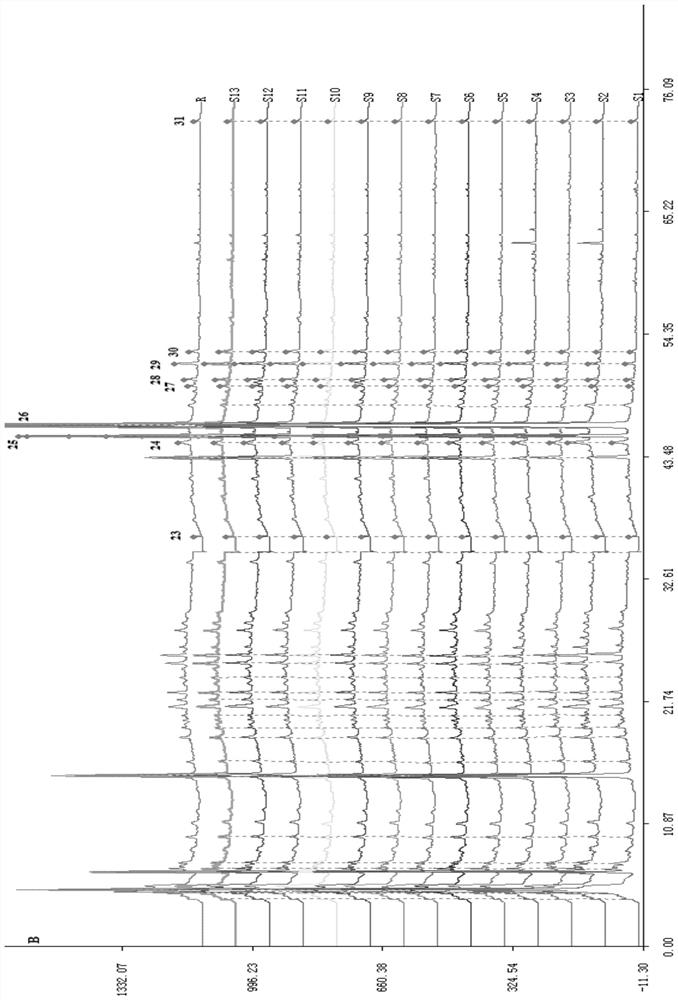

Construction method and application of fingerprint of sweet dream oral liquid

ActiveCN110554127ACharacteristic peak increaseLarge peak capacityComponent separationStationary phaseCurative effect

The invention discloses a construction method and application of a fingerprint of sweet dream oral liquid. The method comprises the following steps: preparing a test solution, preparing a reference solution, optimizing and determining chromatographic conditions, measuring the fingerprint and processing the obtained fingerprint by using fingerprint software. Chromatographic columns with different stationary phases are connected through a six-way valve; gradient elution is performed by the same mobile phase; and various characteristic index components are well separated. Compared with an existing established fingerprint method, the method achieves that characteristic components of the sweet dream oral liquid can be separated and detected as many as possible, obtains more fingerprint characteristic peaks, and more comprehensively reflects component information of the oral liquid. The method further has the advantages of being easy and convenient to operate, high in precision, good in stability and reproducibility and the like, and the quality of the sweet dream oral liquid can be evaluated more comprehensively and scientifically, so that the quality and the curative effect of the product are guaranteed, and reference is provided for perfection of the quality standard of the product.

Owner:SHANDONG UNIV

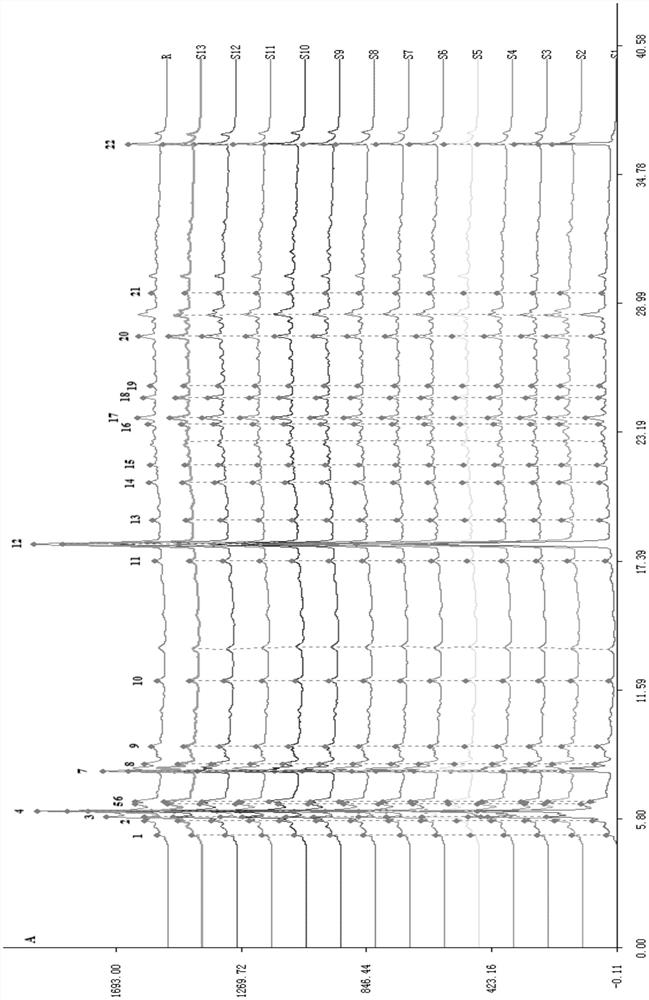

Method for establishing fingerprint of ginseng fruit medicinal material and standard fingerprint thereof

ActiveCN110398551AEnsure consistent qualitySimple and efficient operationComponent separationHplc fingerprintFingerprint

The invention relates to the technical field of fingerprints of traditional Chinese medicinal materials, and particularly relates to a method for establishing a fingerprint of a ginseng fruit medicinal material and a standard fingerprint thereof. The method for establishing the fingerprint of the ginseng fruit medicinal material provided by the invention includes the following steps of: extractingthe ginseng fruit medicinal material by using methanol, and then performing high performance liquid chromatography analysis on the obtained extracting solution, selecting a suitable mobile phase, controlling a gradient elution program, establishing an HPLC fingerprint, and combining a principal component analysis method to better evaluate the quality of the ginseng fruit medicinal material and ensure the consistency of the quality of the ginseng fruit medicinal material. The method provided by the invention is simple and convenient to operate, is accurate and reliable, can make up for the deficiencies of an existing quality control technology, better improves the quality control technology of the ginseng fruit medicinal material, avoids the singleness and limitation of quality control, provides a scientific basis for the quality control of the ginseng fruit medicinal material, and lays a foundation for improving the quality control level of the ginseng fruit medicinal material.

Owner:吉林省集安益盛药业股份有限公司

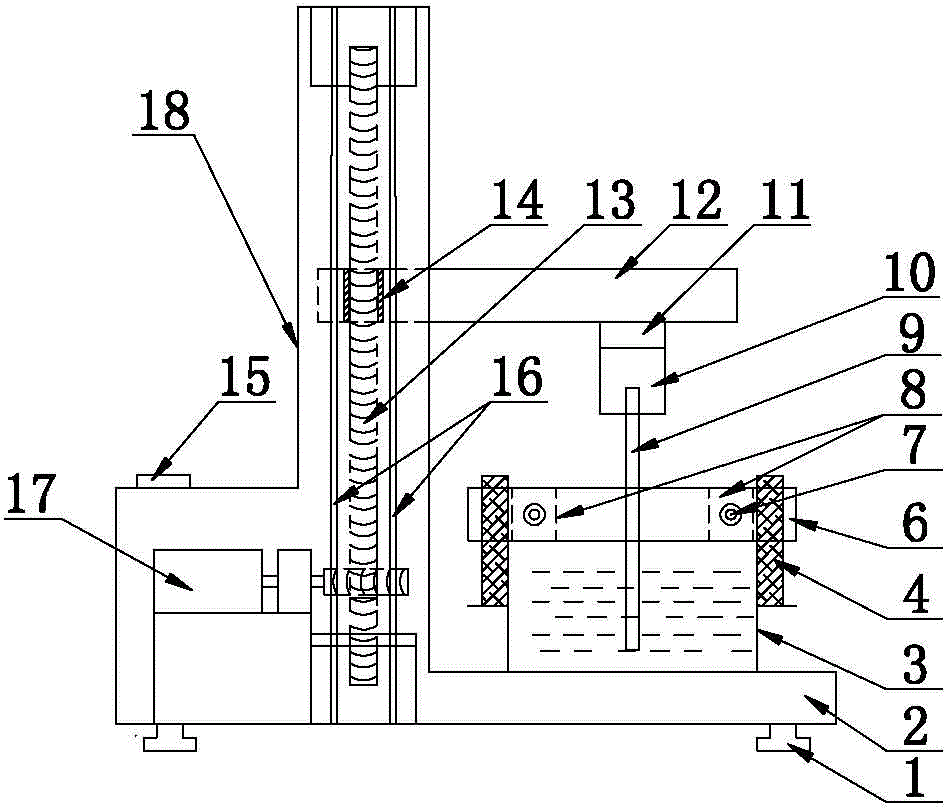

Dried noodle smoothness detection device

ActiveCN102809532BEvaluation qualityEase of evaluationUsing mechanical meansMaterial analysisBiochemical engineering

Owner:KEMEN NOODLE MFG CO LTD

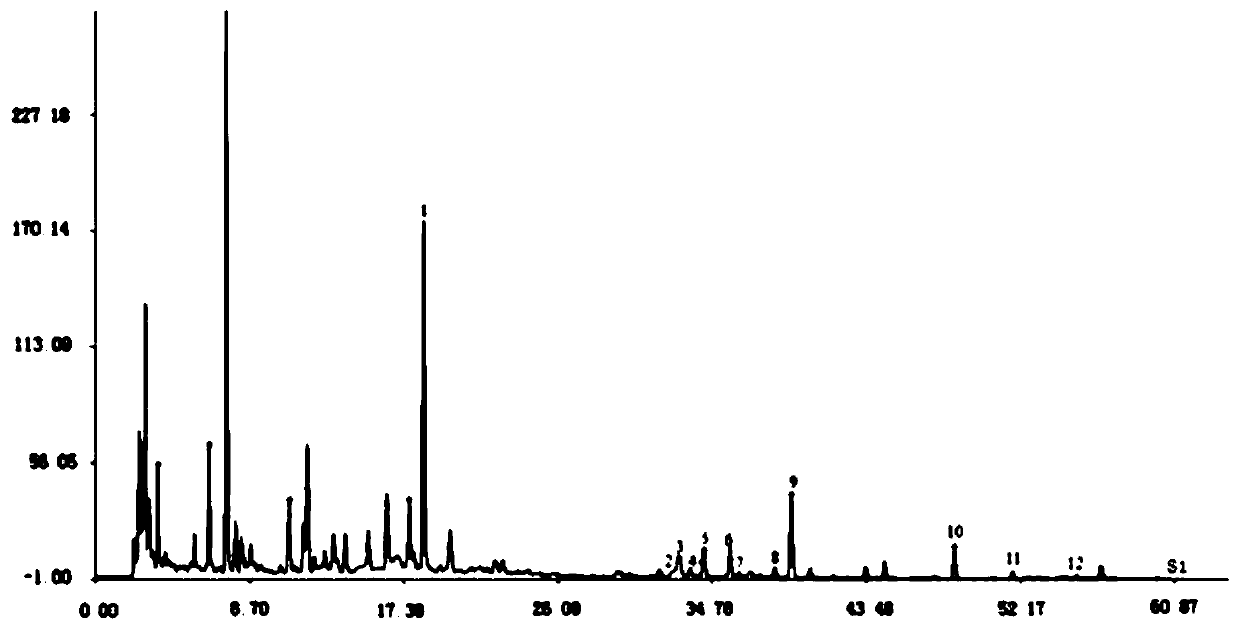

Gas chromatography-mass spectrometry-based construction method for characteristic spectrum of Spina date seed oil and application thereof

ActiveCN110133120ASimple sample preparationAccurate evaluationComponent separationChemistryGas chromatography–mass spectrometry

The invention discloses a gas chromatography-mass spectrometry-based construction method for a characteristic spectrum of Spina date seed oil and an application thereof, belongs to the technical fieldof detection, and aims at solving the problem that the existing methods for evaluating Spina date seed oil are complicated in treatment process. The method comprises the following steps of (1) carrying out petroleum ether Soxhlet extraction on Spina date seed powder to obtain Spina date seed oil, filtering the Spina date seed oil through a derived filter membrane to obtain a test sample; (2) measuring a chemical characteristic spectrum of the Spina date seed oil through a gas chromatography-mass spectrometry hyphenated technology; and (3) carrying out spectrum analysis to determine that the characteristic spectrum of the Spina date seed oil comprises 9 characteristic peaks. The method is concise in sample pretreatment, convenient and good in reproducibility, is capable of accurately reflecting certain important characteristic information of the Spina date seed oil, and can be used for the quality of the Spina date seed oil.

Owner:汉方萃取生物科技(海南)股份有限公司

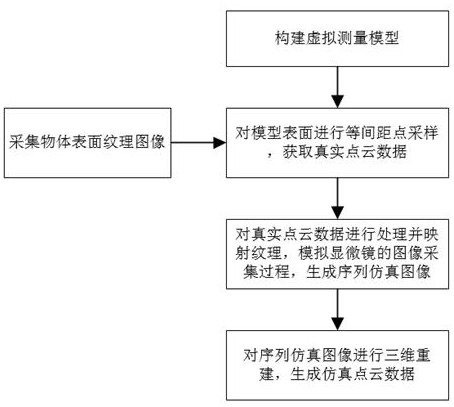

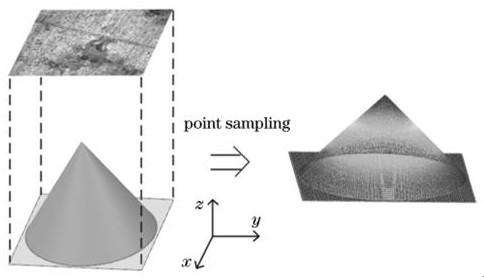

Three-dimensional shape reconstruction simulation method based on infinite focusing scanning

PendingCN114078186AEvaluation qualityDetails involving 3D image data3D modellingThree dimensional modelEvaluation algorithm

The invention provides a three-dimensional shape reconstruction simulation method based on infinite focusing scanning, and the method comprises the steps: constructing a three-dimensional model, and collecting a real texture image of the surface of an object; performing equal-interval point sampling on the surface of the model according to the image resolution to obtain real point cloud data; processing the real point cloud data, mapping textures, simulating an image acquisition process of a microscope, and generating a sequence simulation image; and performing three-dimensional reconstruction on the sequence simulation image to generate simulation point cloud data. According to the method, any simulation measurement model with the continuous surface can be established, the complex and changeable surface topography can be simulated, the real point cloud data of the surface of the complex model can be obtained through the point sampling algorithm, the reconstructed point cloud data is compared with the real point cloud data, and the quality of the focusing evaluation algorithm can be quantitatively evaluated.

Owner:南京璟麒智能机器人系统控制研究院有限公司

Flour product characteristic mechanism detector

InactiveCN102062771ATest qualityReasonable evaluation of qualityTesting starch susbtancesProduct characteristicsFermentation

The invention discloses a flour product characteristic mechanism detector, which belongs to detectors. The detector comprises a shell, a wind pressure sensor and a detecting head, wherein the shell is provided with a power supply, a wind pressure display meter, an air blow value regulator and an electronic sensor; a blower is arranged in the shell; the air blow value regulator is connected with the blower and the electronic sensor respectively; the wind pressure display meter is connected with the electronic sensor and the wind pressure sensor respectively; the wind pressure sensor is arranged in a lower bracket; and the detecting head is connected with the blower through an air pipe and arranged on the upper part of the lower bracket. Compared with the prior art, the flour product characteristic mechanism detector has the characteristics of accurately detecting different fermentation environments of flour products and the quality of the flour products produced under different mature conditions, rationally evaluating the quality of the flour products and the like, so the detector has extremely high popularization and application value.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

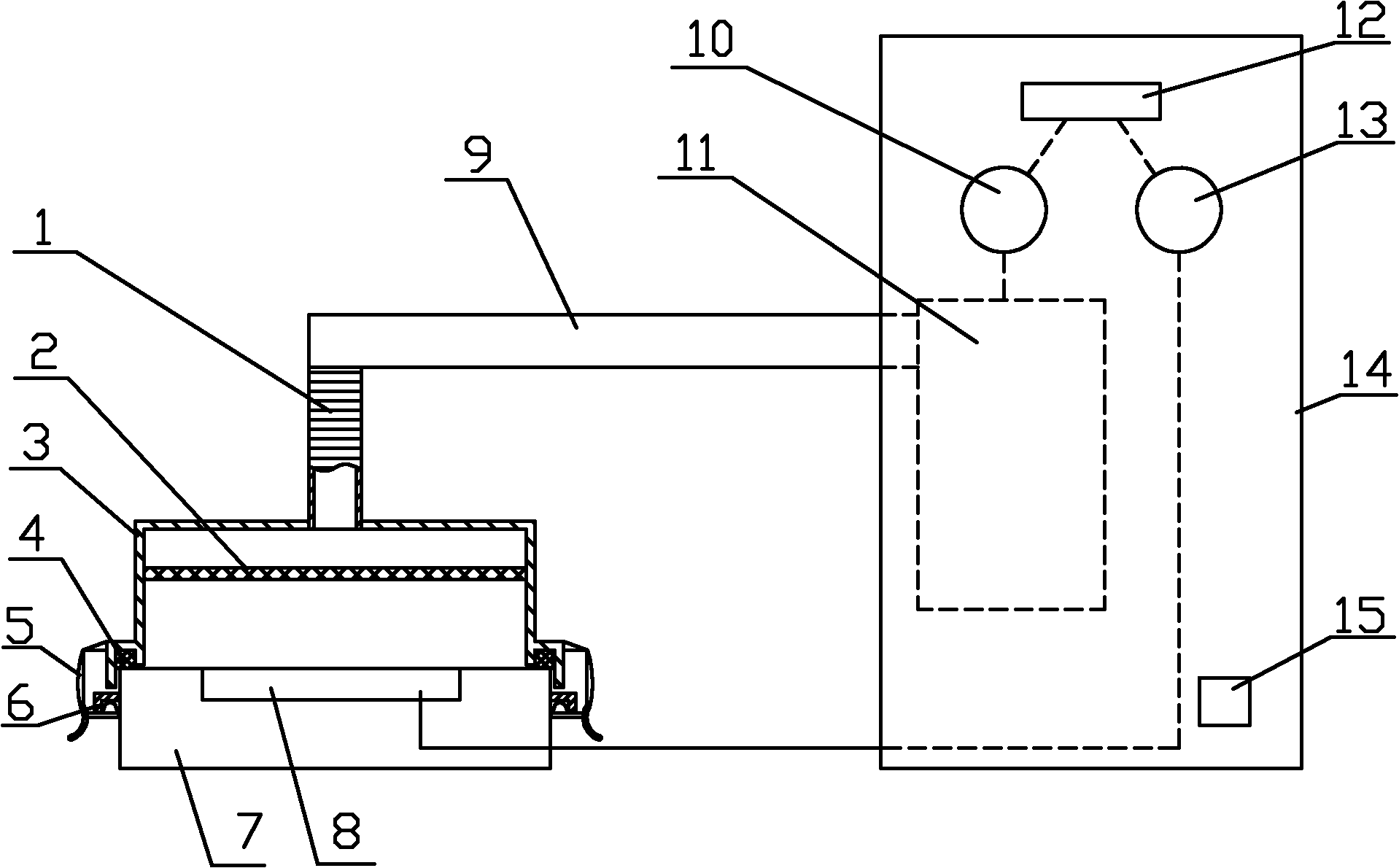

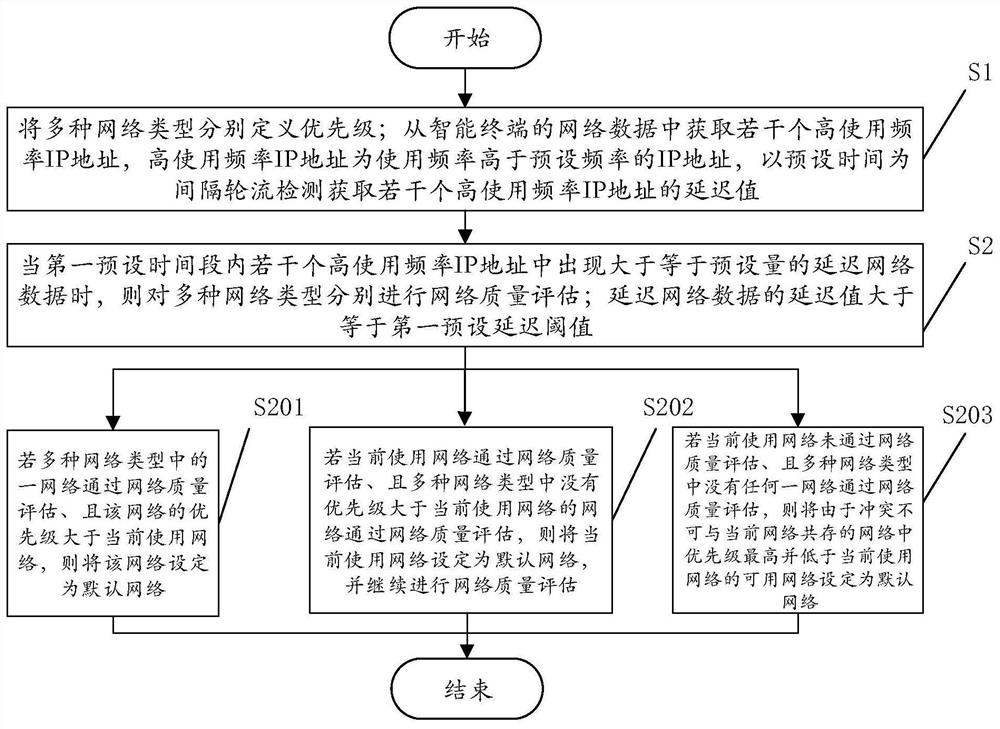

Multi-network switching method and system of intelligent terminal and computer readable storage medium

ActiveCN113055962ABig choiceGuaranteed normal useWireless communicationEngineeringReal-time computing

The present invention provides a multi-network switching method and system of the intelligent terminal and the computer readable storage medium, the network quality is evaluated through the network delay value and the network downlink throughput rate, the default network is set in combination with the priorities of all networks supported by the intelligent terminal, network switching is achieved, and compared with network switching in the prior art, all supporting networks including the current practical network can be evaluated, the selection space of the intelligent terminal for the network is large when the intelligent terminal uses the network, and the multi-network function of the intelligent terminal is fully played.

Owner:BLACKSHARK TECH NANCHANG CO LTD

Full-reference high-dynamic image quality evaluation method based on multi-feature fusion

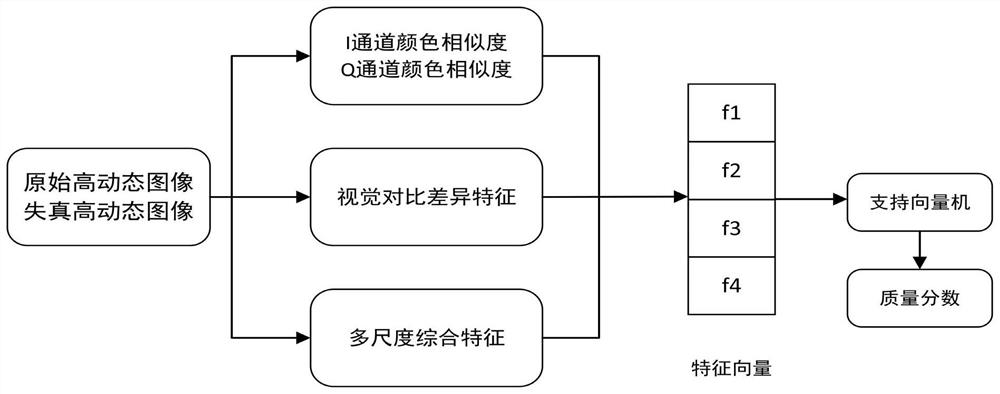

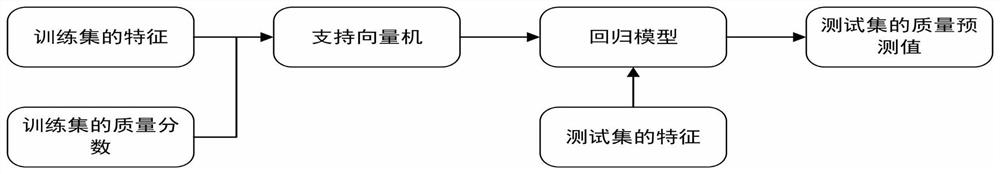

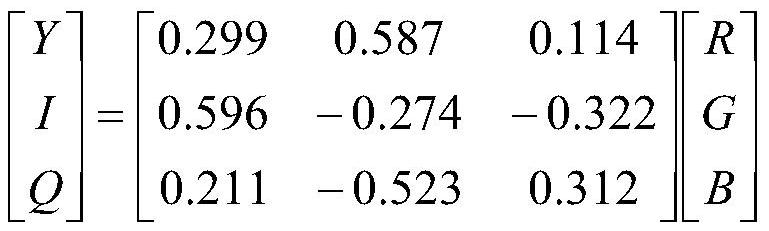

ActiveCN111768362AIn line with visual perception characteristicsEvaluation qualityImage enhancementImage analysisImaging qualityMulti feature fusion

The invention provides a full-reference high-dynamic image quality evaluation method based on multi-feature fusion. The full-reference high-dynamic image quality evaluation method is mainly divided into a feature extraction stage and a training regression stage. In the feature extraction stage, features of the image are extracted in three directions, and two color similarity features of the imageare extracted in the color direction by using a color similarity method extraction method; visual contrast difference features are extracted by adopting a visual difference prediction method in a visual contrast difference direction; a log-Gabor filter is used for extracting multi-scale features in different frequency scales and directions according to the multi-scale comprehensive feature direction; and the quality of the high-dynamic image is predicted by using a machine learning method in a training regression stage. The algorithm provided by the invention can accurately and effectively predict the quality of the high-dynamic image.

Owner:SHANGHAI UNIV

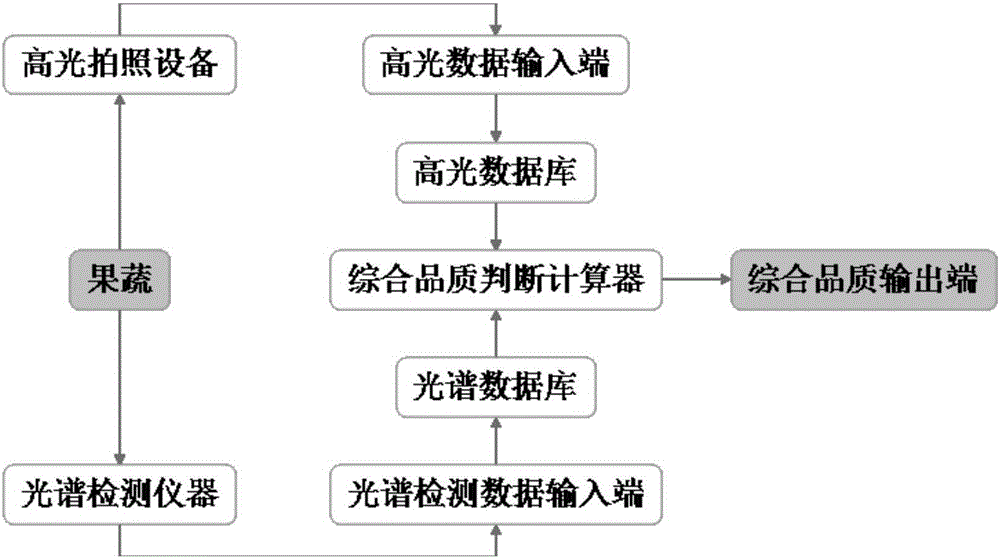

Fruit and vegetable quality highlight photographing and nondestructive spectral scanning determining system

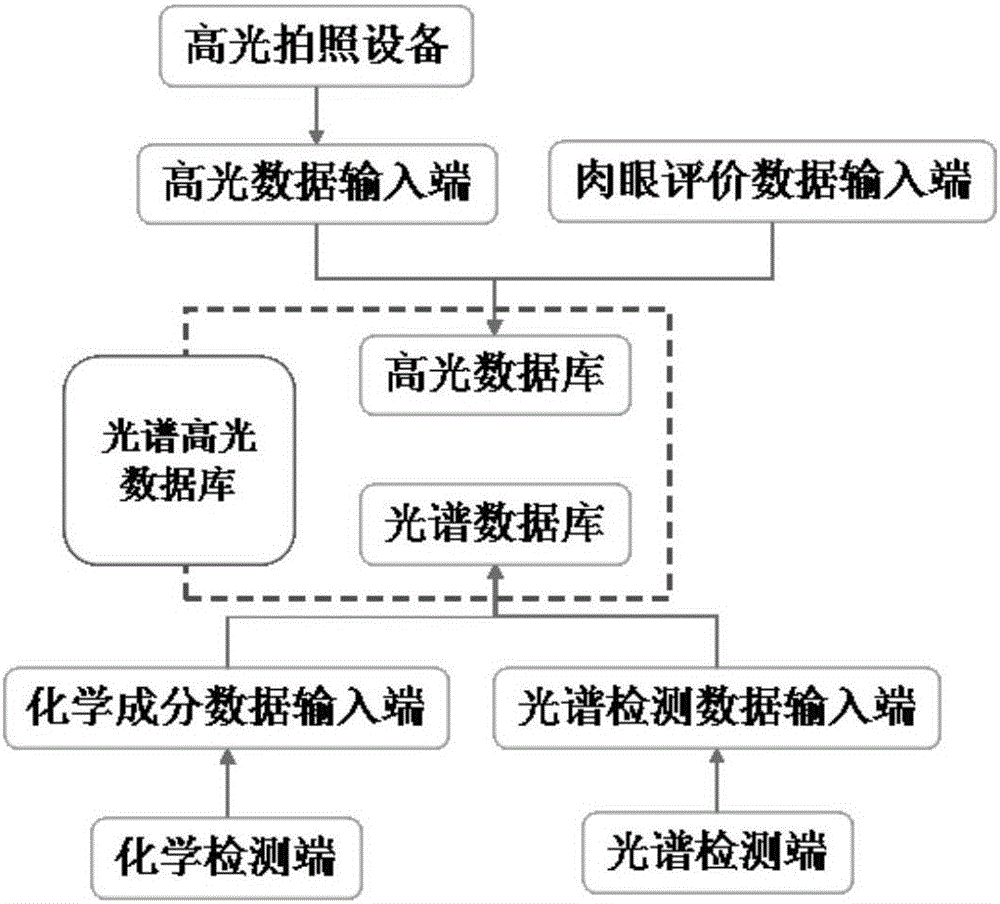

InactiveCN106769900AEvaluation qualityColor/spectral properties measurementsSpectral databaseComputer science

The invention relates to a fruit and vegetable quality highlight photographing and nondestructive spectral scanning determining system. The invention is characterized in that the system comprises a comprehensive quality determination calculator, wherein the comprehensive quality determination calculator is connected with a highlight database and a spectral database, the spectral database is connected with a spectral detection data input end, the highlight database is connected with a highlight data input end, the comprehensive quality determination calculator is connected with a comprehensive quality output end, the highlight data input end receives fruit and vegetable surface highlight photographed data transmitted by a highlight photographing device, and the spectral detection data input end receives fruit and vegetable spectral data detected by a spectral detection instrument. The system of the invention sufficiently utilizes two data forms, i.e. spectral data and highlight data, and the two kinds of data are obtained by adopting a nondestructive way for fruits and vegetables, so that a result calculated by the system according to the two data can evaluate the internal quality and external quality of the fruits.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

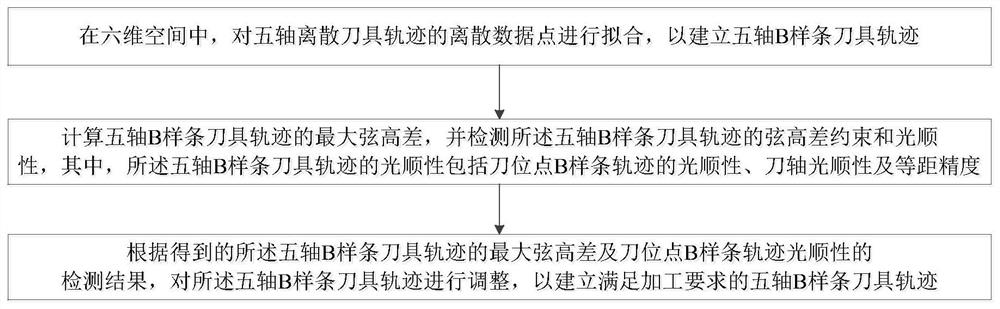

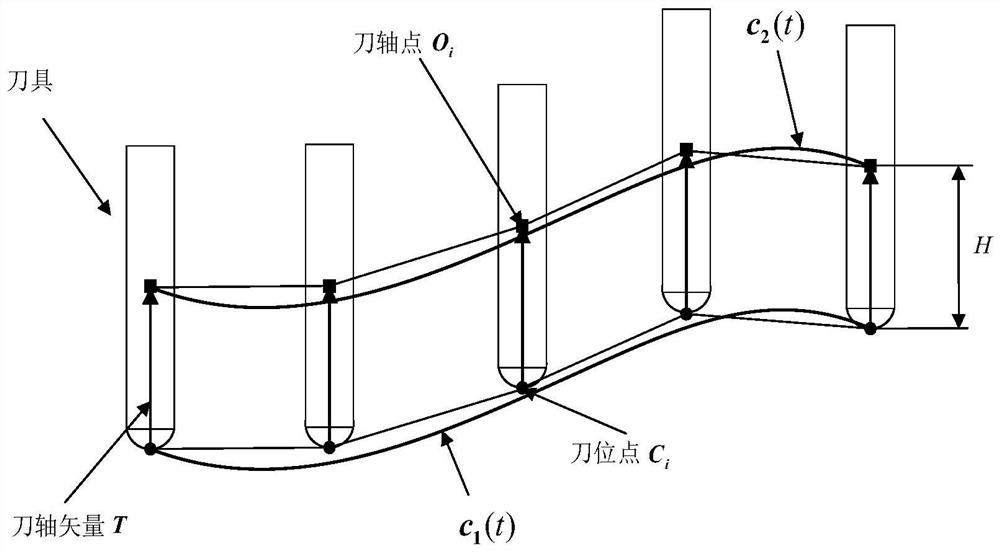

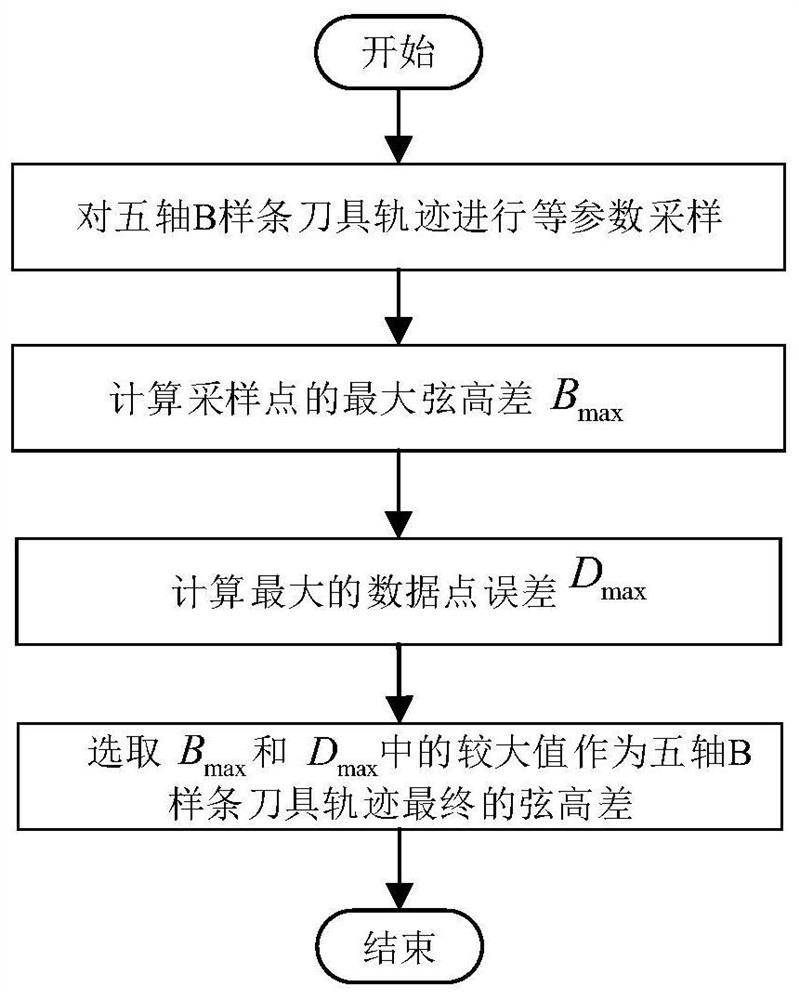

A b-spline fitting method for five-axis tool path

ActiveCN108958161BEvaluation qualityImprove quality and efficiencyNumerical controlCutter locationStructural engineering

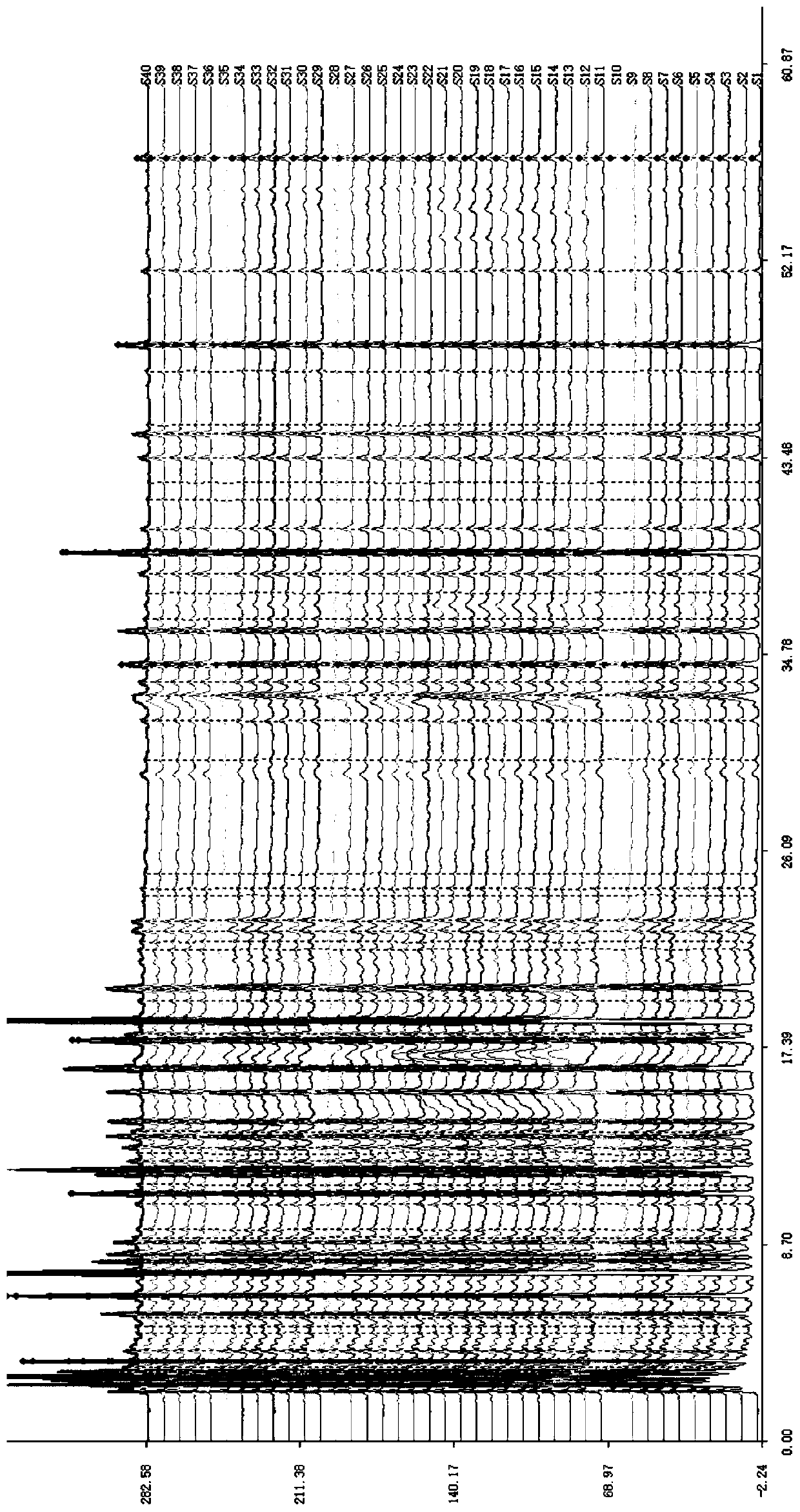

The invention belongs to the numerical control machining related technical field and discloses a B-spline fitting method for a five-axis cutter path. The method includes the following steps that: S1,a five-axis B-spline cutter path is established according to a five-axis discrete cutter path; S2, the maximum chord height difference of the five-axis B-spline cutter path is calculated, and the chord height constraint and smoothness of the five-axis B-spline cutter path are detected, wherein the smoothness of the five-axis B-spline cutter path includes the smoothness of the B-spline path of a cutter location point, and the smoothness and isometric precision of a cutter shaft; and S3, the five-axis B-spline cutter path is adjusted according to the obtained maximum chord height difference of the five-axis B-spline cutter path and the detection result of the smoothness of the five-axis B-spline path of the cutter location point, so that a five-axis B-spline cutter path satisfying a machining requirement is established. With the method of the invention adopted, the quality of the five-axis B-spline cutter path can be comprehensively and efficiently evaluated, and the obtained cutter pathcan satisfy the high-speed and high-precision machining requirement of a five-axis numerically-controlled machine tool.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A HPLC method for the simultaneous determination of seven organic acids in Huzhangnanxing

ActiveCN110243969BEvaluate quality effectivelyEvaluation qualityComponent separationOXALIC ACID DIHYDRATEMedicinal herbs

The invention provides a kind of HPLC method (oxalic acid, L-malic acid, citric acid and fumaric acid) of the HPLC method (oxalic acid, L-malic acid, citric acid and fumaric acid) of a kind of simultaneous determination of 4 kinds of organic acids in S. (succinic acid, cis-aconitic acid and trans-aconitic acid). The HPLC detection method of the present invention can simultaneously measure various organic acid components in the medicinal material Nanxing variegata, and has the advantages of simple operation, high sensitivity, good specificity and high accuracy, and can effectively evaluate the quality of the medicinal material Nanxing variegata.

Owner:CHENGDU UNIV OF TRADITIONAL CHINESE MEDICINE

Content detection method of antiasthmatic tablets

PendingCN114295756AAccurately assess qualityEvaluation qualityComponent separationTest sampleCurative effect

The content detection method comprises the following steps: step 1, preparing a reference substance solution, step 2, preparing a test sample solution, step 3, injecting the reference substance solution and the test sample solution into a high performance liquid chromatograph to obtain a chromatogram, and step 4, calculating the content of hyperoside in a test sample according to the chromatogram. The content of lindley eupatorium lindley in each tablet is not less than 50mg in terms of hyperoside (C21H20O12). The content detection method of the antiasthmatic tablet can objectively, comprehensively and accurately evaluate the quality of the antiasthmatic tablet, and has important significance on guaranteeing the quality of the product while guaranteeing the curative effect of the product.

Owner:JIANGSU 707 NATURAL PHARMA

Method and device for monitoring a seam, in particular when joining by means of laser radiation

ActiveCN108883495BEvaluation qualityArc welding apparatusLaser beam welding apparatusLaser processingEngineering

The present invention relates to a method for monitoring a joint, in particular a method for monitoring a joint during a joining process by means of laser radiation, in which method: measurement is made in front of the machining point in the machining direction a joint to detect the position and geometry of the joint; determine a position of the seam behind the process at least from the position of the joint in front of the process; and The seam is measured at the determined position behind the processing point in the processing direction to detect geometric properties of the seam. The invention also relates to a device for carrying out the method and a laser processing head equipped with such a device.

Owner:PRECITEC GMBH

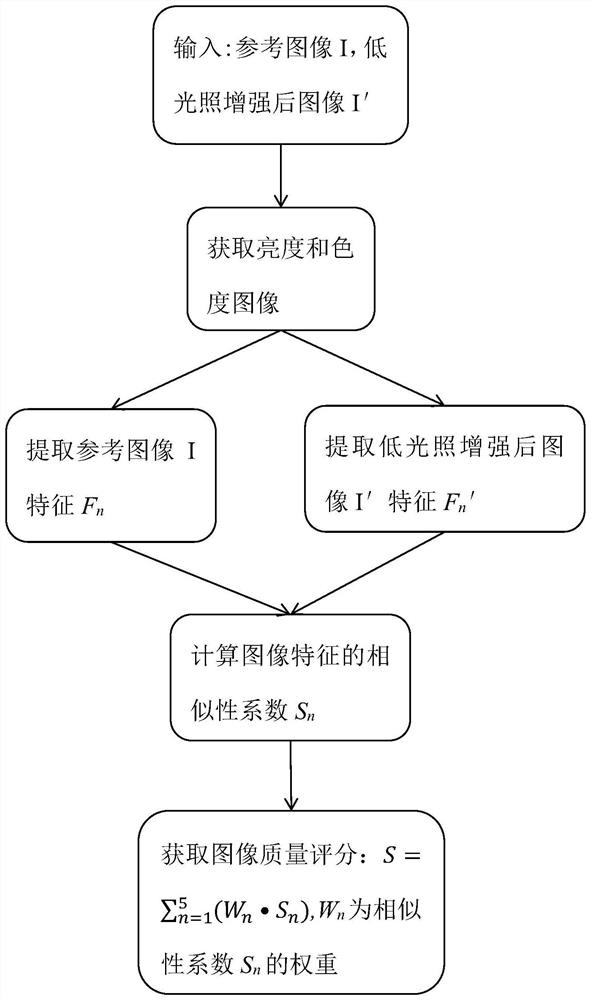

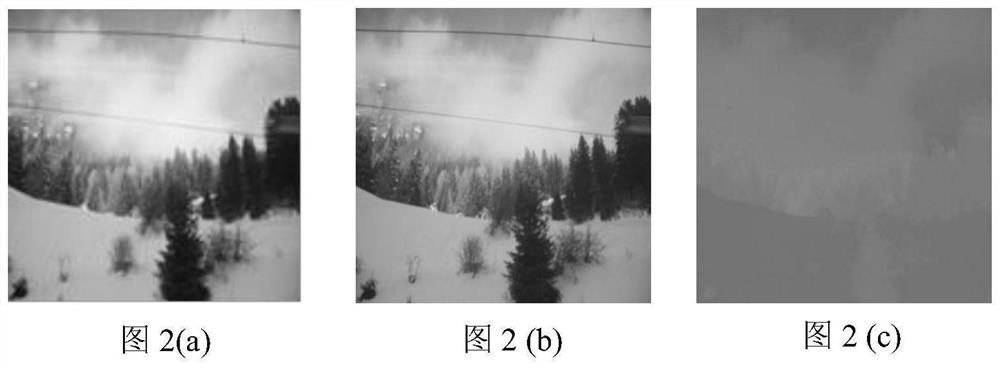

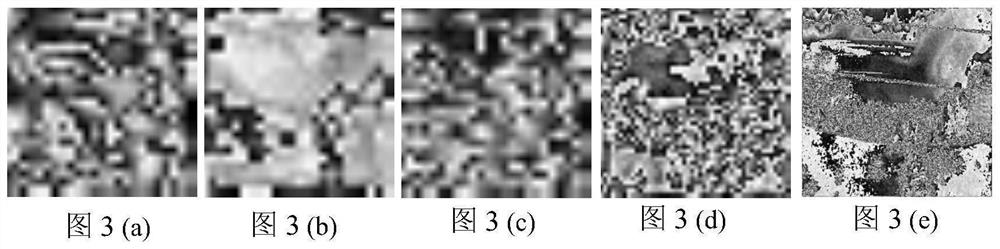

Robust low-illumination enhanced image quality evaluation method

ActiveCN112381761AEvaluate brightnessEvaluation ContrastImage enhancementImage analysisFeature extractionImaging quality

The invention discloses a robust low-illumination enhanced image quality evaluation method, which comprises the following steps: performing color space conversion on an input image, separating to obtain brightness and chrominance channel information of the image, and synthesizing a brightness image and a chrominance image according to the brightness and chrominance channel information; according to the image information obtained through separation, using a feature extraction network to extract brightness features, contrast features, color features, global structure features and texture detailfeatures of the reference image and the image after low illumination enhancement; calculating similarity coefficients of brightness features, contrast features, color features, global structure features and texture detail features of the reference image and the low-illumination enhanced image; and obtaining a weight parameter of an optimal image feature similarity coefficient through a method of training and optimizing a neural network, and adding and summing the similarity coefficients according to the weight parameter to obtain a final quality score of the image after low-light enhancement.

Owner:SOUTH CHINA UNIV OF TECH +1

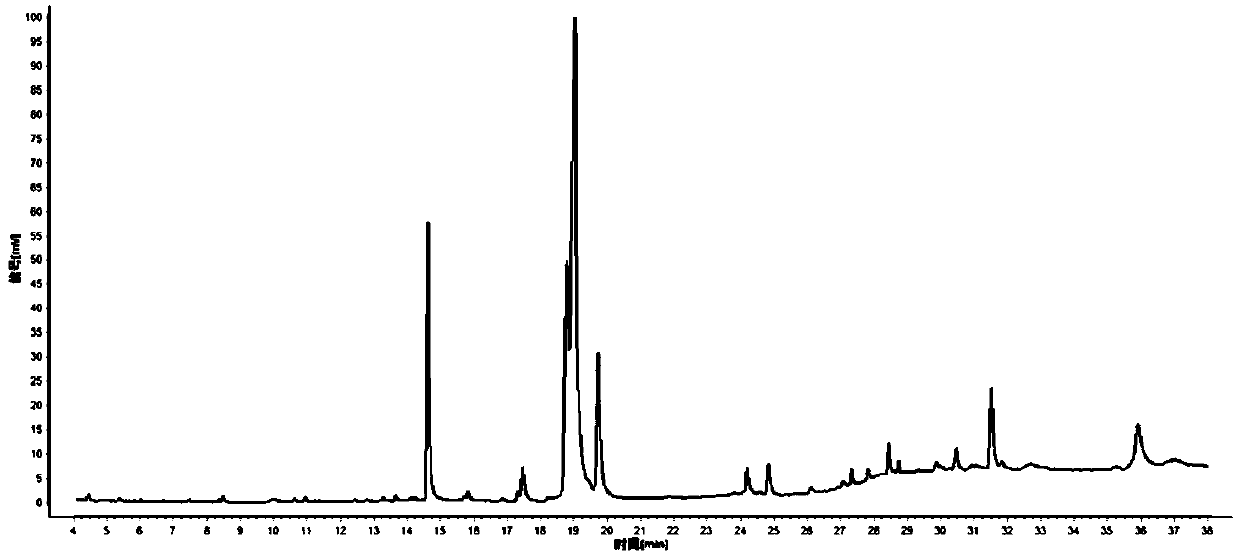

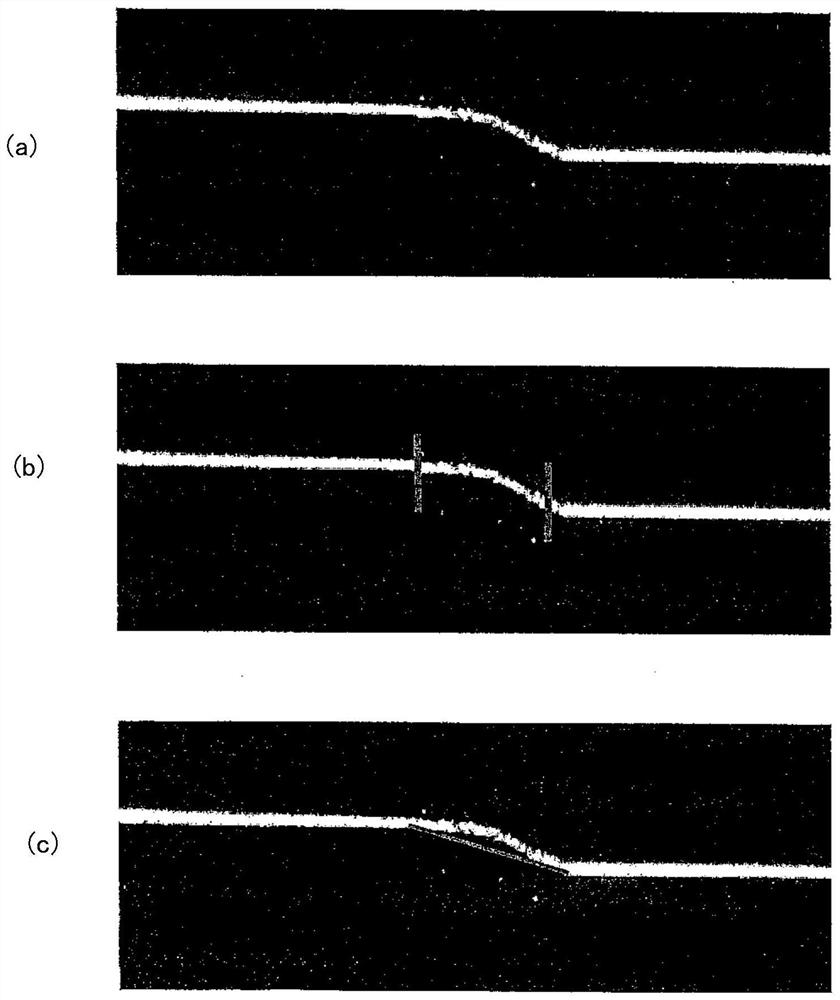

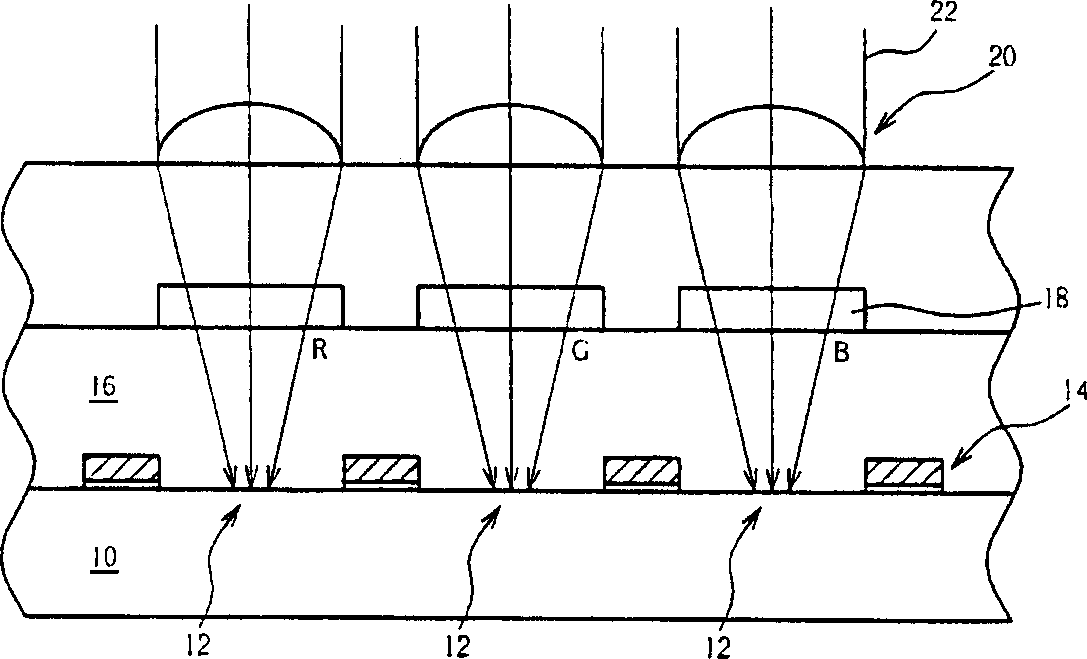

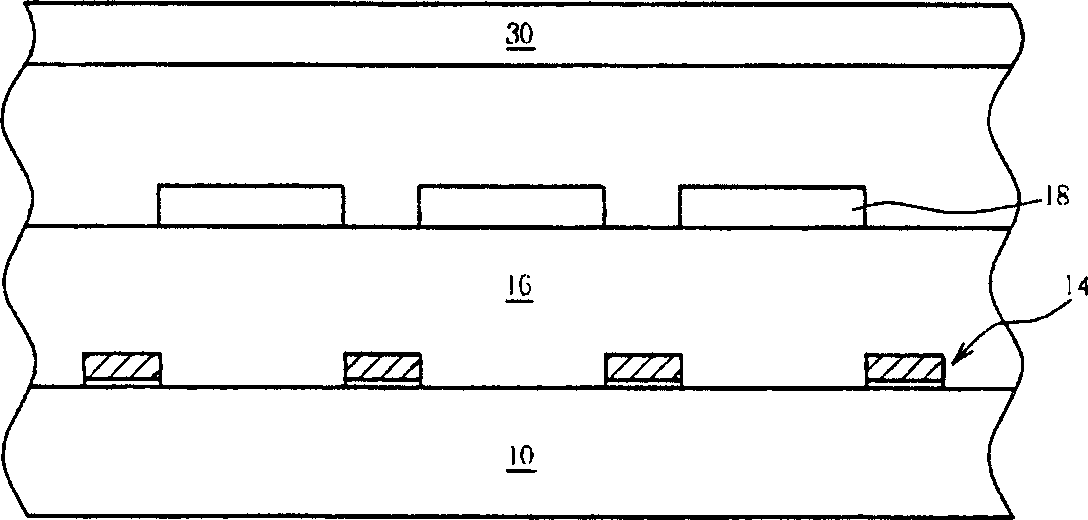

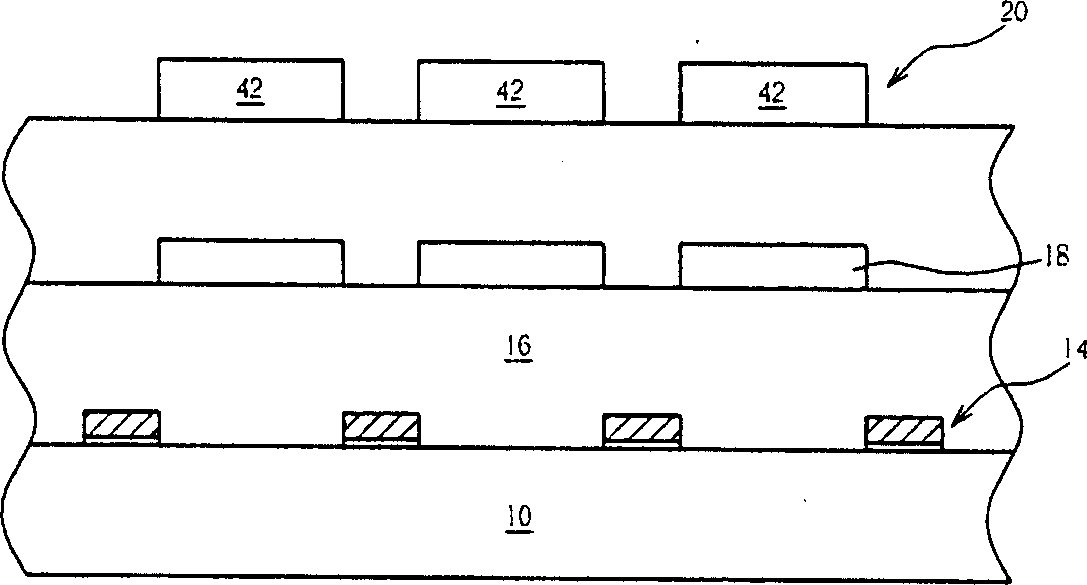

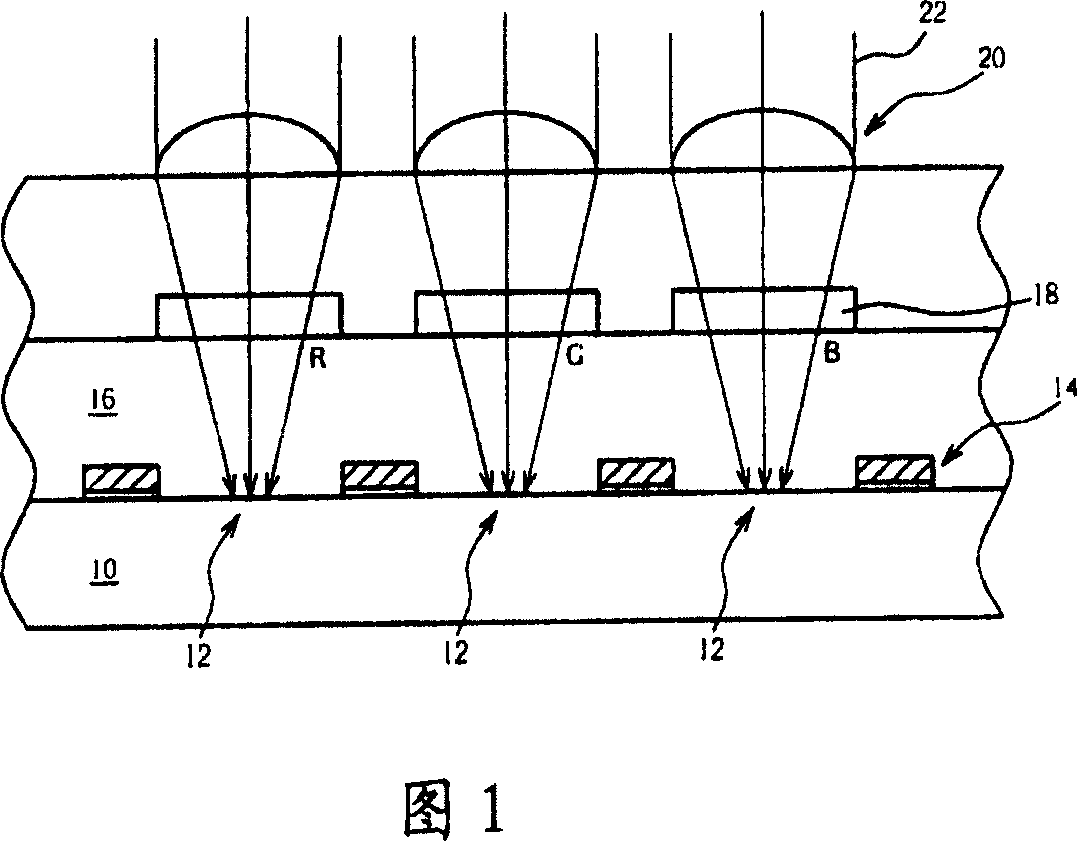

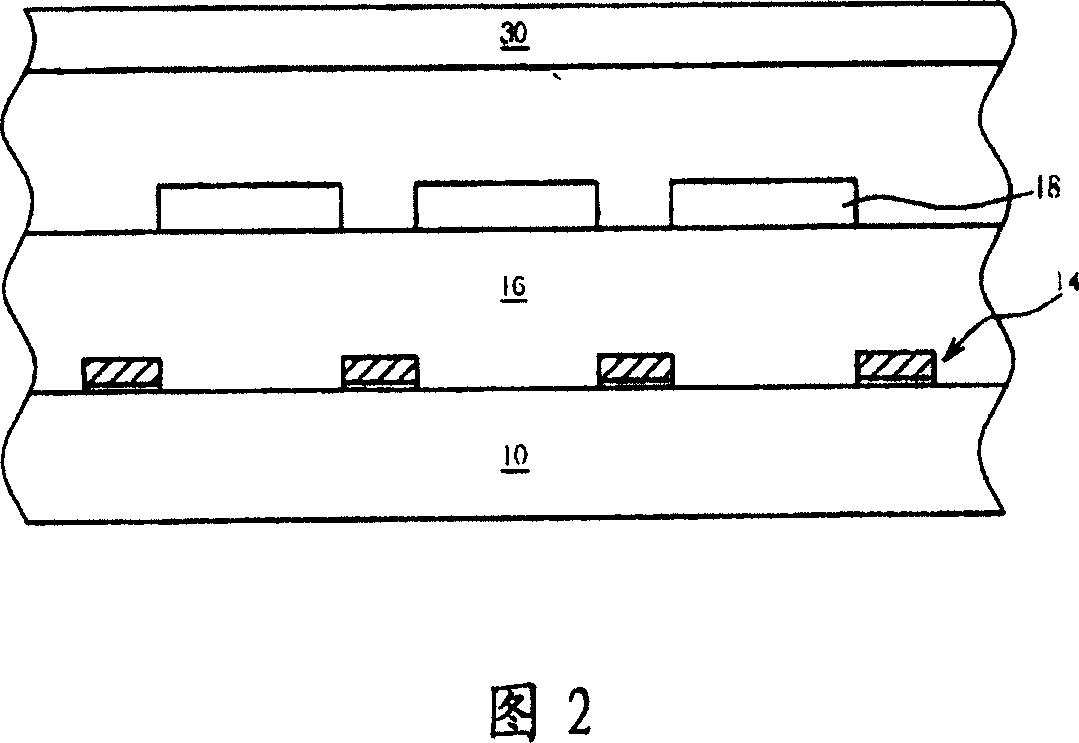

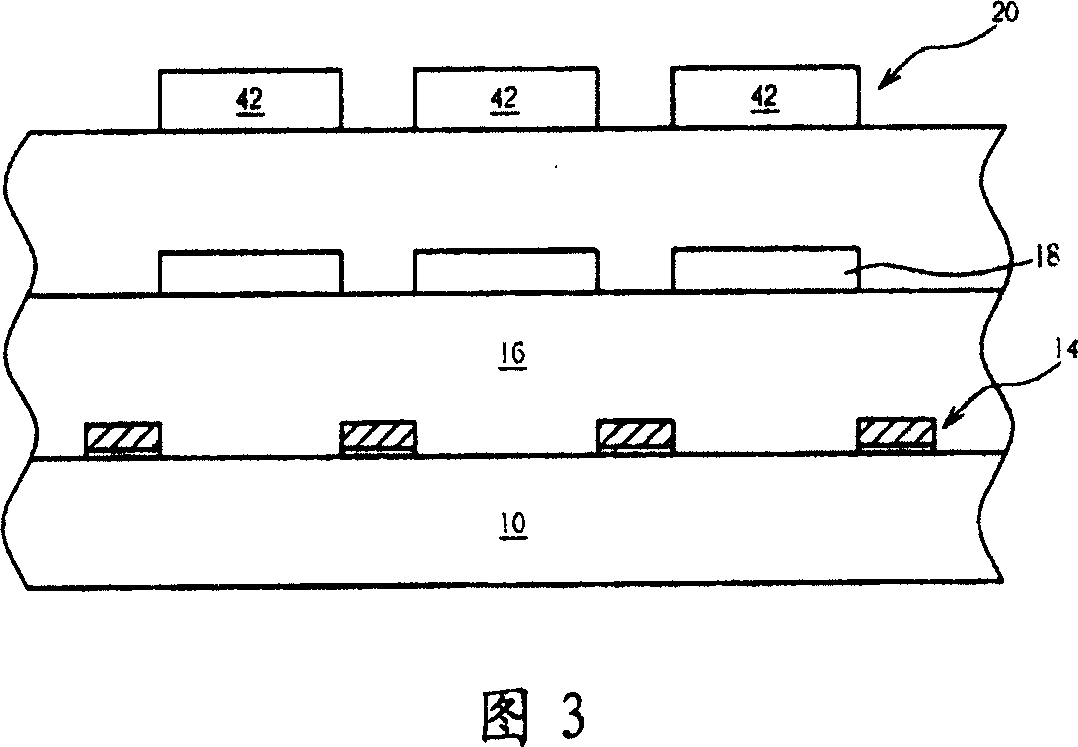

Monitoring marking layout for microlens baking process

ActiveCN1837862AAssess mobilityEvaluation qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringLevel line

This invention relates to a monitoring marking layout for microlens baking process. Wherein, it comprises: two vertical-line pattern paralleled with each other, and one horizontal-line pattern connected to the vertical to define a pointer path and fluidize the vertical pattern to lead the horizontal pattern fusing along the path and forming design; then, uses the design to decide whether there once a roasting process to the microlens.

Owner:UNITED MICROELECTRONICS CORP

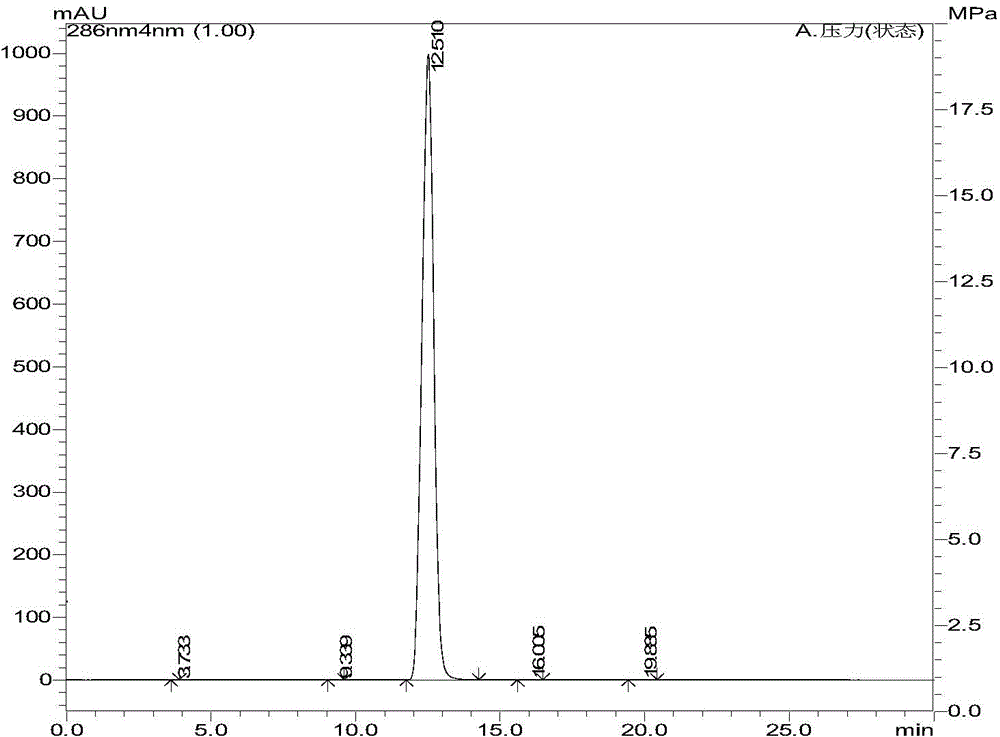

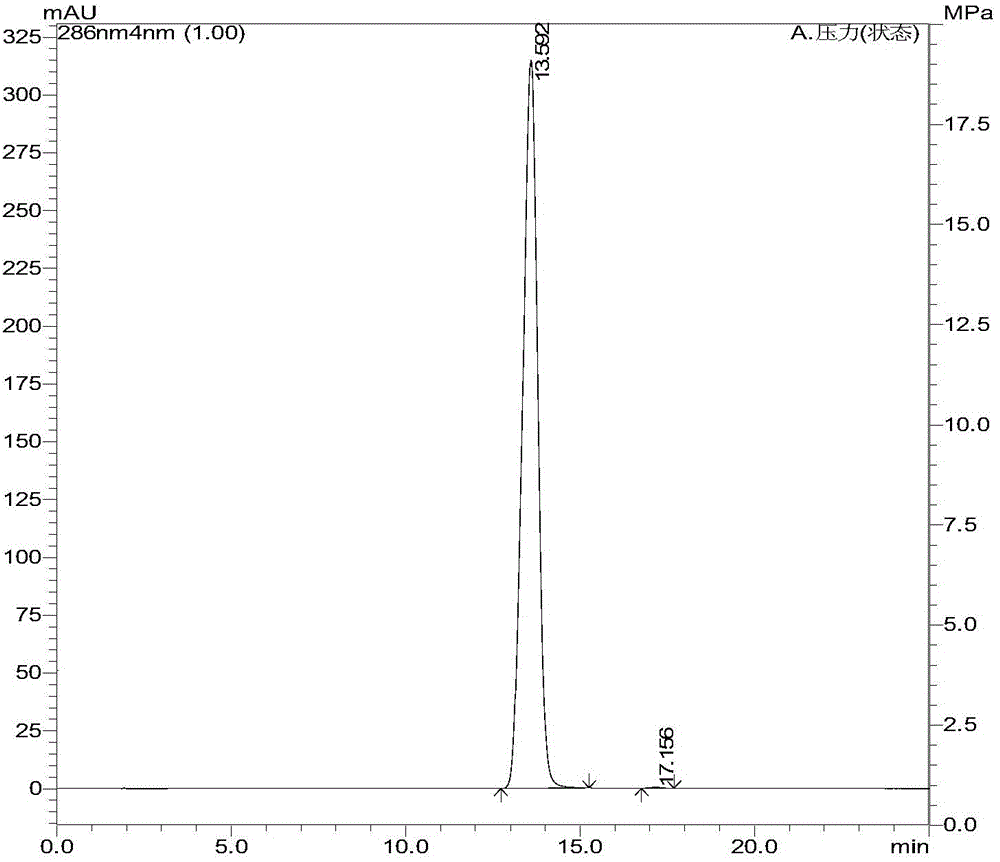

A kind of high performance liquid chromatography analysis method of neconazole hydrochloride

ActiveCN104133016BThe analytical method is practical and reliableImprove stabilityComponent separationUltraviolet detectorsColumn temperature

The invention relates to a high performance liquid chromatography analysis method of neticonazole hydrochloride and belongs to the technical field of pharmaceutical analysis. The high performance liquid chromatography analysis method utilizes an octadecyl bonded silica-filled chromatographic column having specifications of 4.6mm*150mm, 5 microns or 4.6mm*200mm, 5 microns or 4.6mm*250mm, 5 microns, an acetonitrile-water mixture as a mobile phase having a volume ratio of acetonitrile to water of 45-65: 35-55, a flowing rate of 0.5-0.9mL / min, a column temperature of 30-40 DEG C, a ultraviolet detector wavelength of 280-290nm, and a sample introduction volume of 5-50 microliters. The high performance liquid chromatography analysis method of neticonazole hydrochloride can utilize a common liquid chromatograph, has low equipment requirements, utilizes two easily available mediums of the mobile phase, has high feasibility, has simple and convenient operation processes, has good applicability and can be widely used for neticonazole hydrochloride and its preparation.

Owner:JIANGSU YUNYANG PHARMA GRP

A method for constructing the fingerprint of Tianmeng Oral Liquid and its application

ActiveCN110554127BCharacteristic peak increaseLarge peak capacityComponent separationStationary phaseBiochemical engineering

The invention discloses a method for constructing the fingerprint of Tianmeng Oral Liquid and its application. The method includes: preparation of the test solution, preparation of the reference solution, optimization of chromatographic conditions, measurement and analysis of the obtained spectrum by fingerprint software to process. The present invention adopts chromatographic columns of different stationary phases to be connected through a six-way valve, and the same mobile phase is gradiently eluted, and a variety of characteristic index components are well separated. As many characteristic components as possible are separated and detected, and more characteristic peaks of fingerprints are obtained, which can more comprehensively reflect the component information of Tianmeng Oral Liquid. Good and other advantages, it can more comprehensively and scientifically evaluate the quality of Tianmeng Oral Liquid, so as to ensure the quality and curative effect of the product, and provide a reference for the improvement of its quality standards.

Owner:SHANDONG UNIV

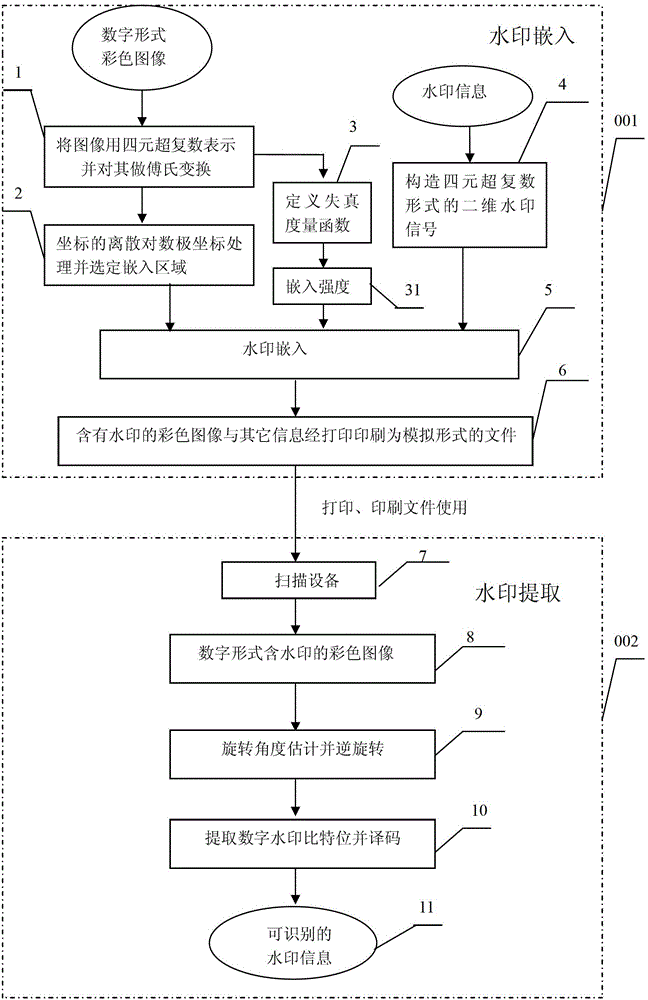

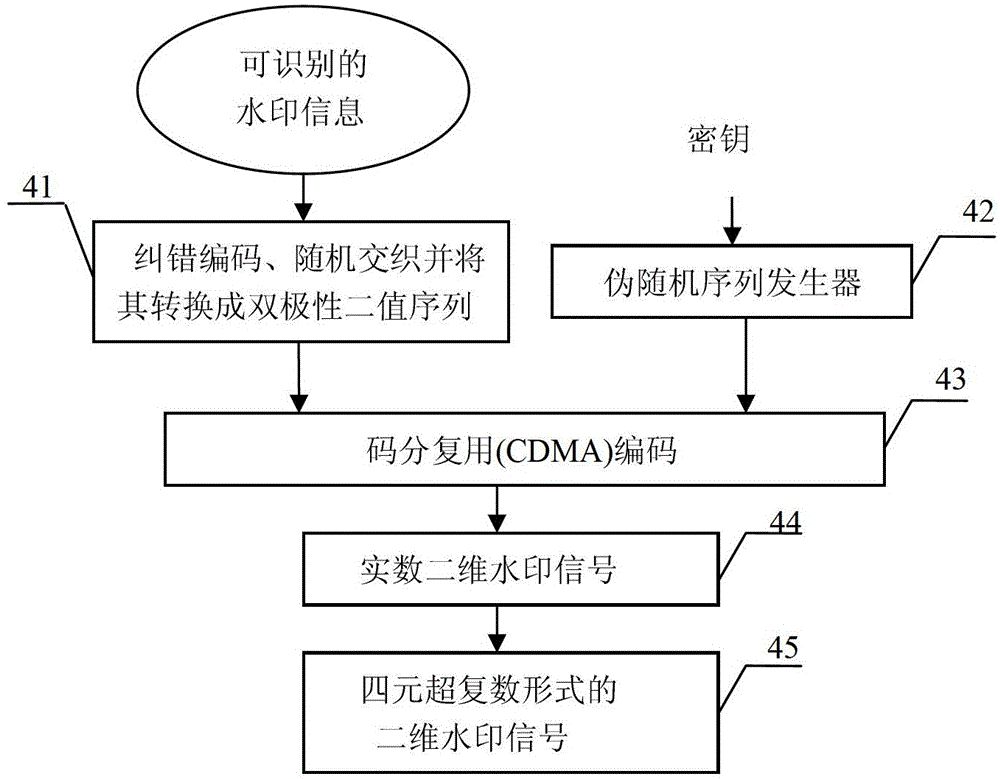

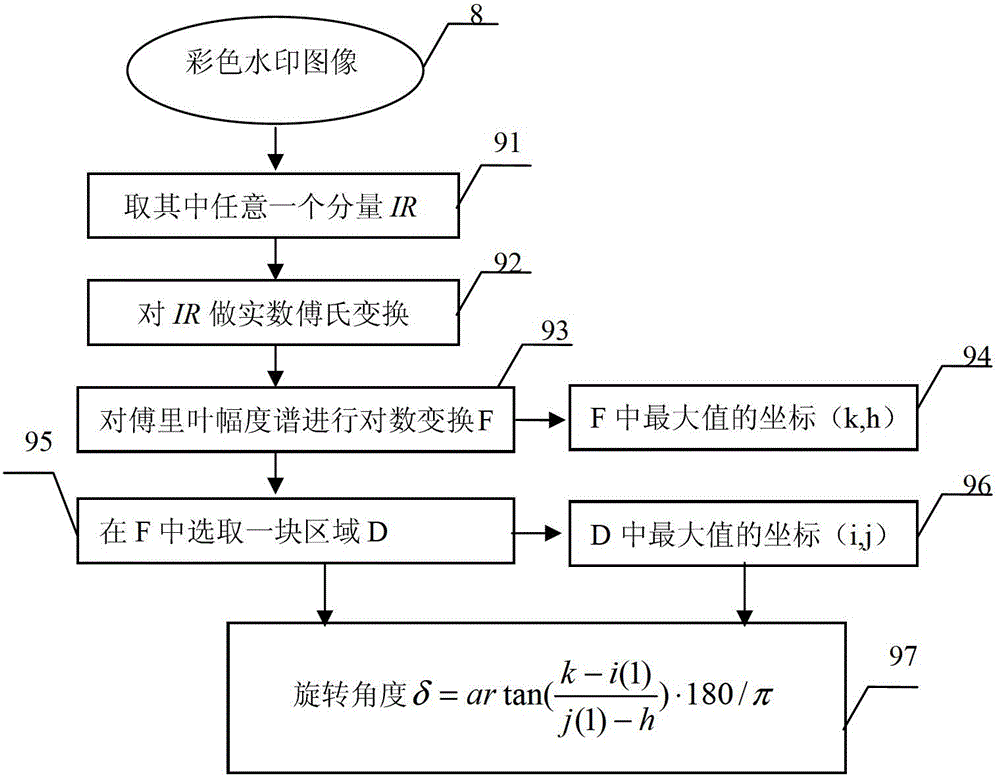

Color image digital watermark method capable of resisting stamping, printing and scanning processes

InactiveCN102880999BFast estimate of rotation angleObjective evaluation of qualityImage data processing detailsColor imageImaging quality

The invention relates to a color image digital watermark method capable of resisting stamping, printing and scanning processes and belongs to the technical fields of anti-counterfeit, authentication and information safety. The invention adopts the technical scheme that an L*a*b* color space of a color carrier image is represented by quaternary supercomplex number; readable watermark information is encoded and modulated to generate a two-dimensional watermark signal in a form of the quaternary supercomplex number; and the watermark embedding position is determined by a uniform discrete logarithmic polar coordinates method. The color image digital watermark method capable of resisting stamping, printing and scanning processes has the beneficial effects that the embedding capacity of watermarks is large; the robustness resisting synchronous distortion is strong; the gap of an image quality evaluation function of the color image is filled; self-adaption embedding of the watermarks with highest strength is realized; the robustness resisting rotation, compression, stamping, printing and scanning attacks is strong; and the method can be widely applied to anti-counterfeiting domain authentication of various certificates and printed products.

Owner:JILIN UNIV

Monitoring marking layout for microlens baking process

ActiveCN100373173CAssess mobilityEvaluation qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringLevel line

This invention relates to a monitoring marking layout for microlens baking process. Wherein, it comprises: two vertical-line pattern paralleled with each other, and one horizontal-line pattern connected to the vertical to define a pointer path and fluidize the vertical pattern to lead the horizontal pattern fusing along the path and forming design; then, uses the design to decide whether there once a roasting process to the microlens.

Owner:UNITED MICROELECTRONICS CORP

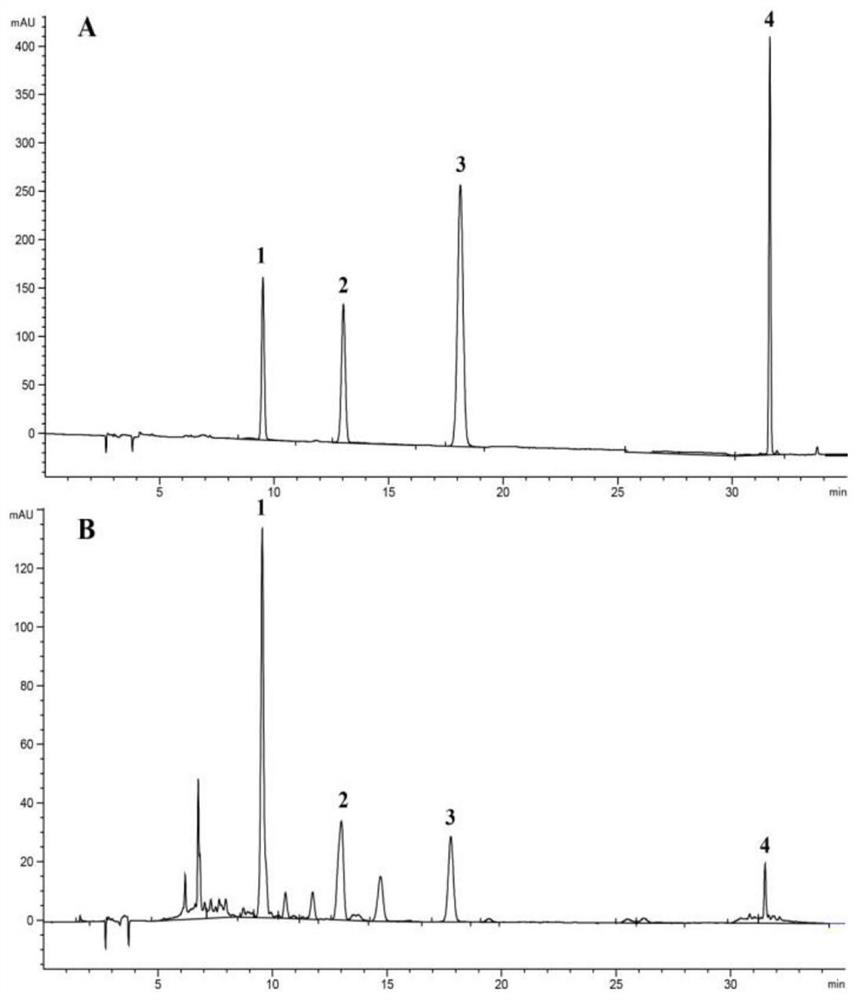

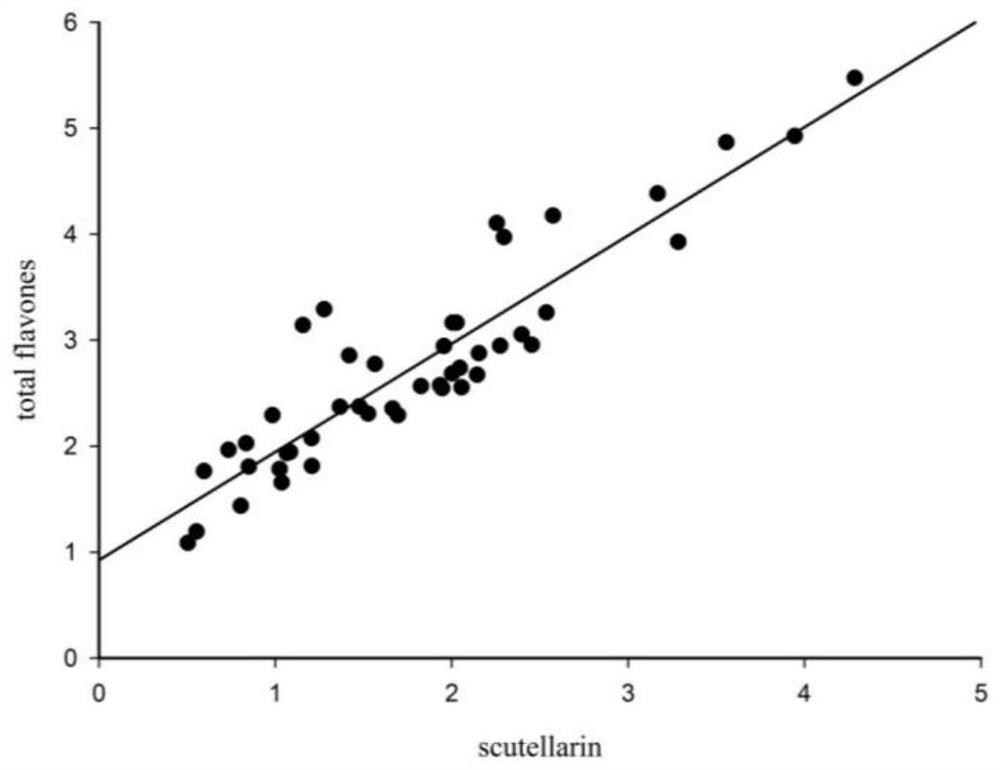

A method for simultaneous determination of 4 kinds of active ingredients in Dengzhan flower

ActiveCN110346494BEvaluation qualityStrong specificityComponent separationScutellareinO-Phosphoric Acid

The invention discloses a method for simultaneously determining the content of four active ingredients in scutellaria breviscapine, the four active ingredients are scutellarin, scutellarin, scutellarein and apigenin, and the method adopts the following chromatographic conditions: Column: C 18 Liquid chromatography column; flow rate: 0.8~1.2ml / min; column temperature: 25℃~35℃; detection wavelength: 335nm; injection volume: 2μl; mobile phase A: water; mobile phase B: acetonitrile; mobile phase C: 0.3% phosphoric acid in water; using gradient elution. The invention has the advantages that the measuring method is accurate, reliable, scientific and reasonable.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

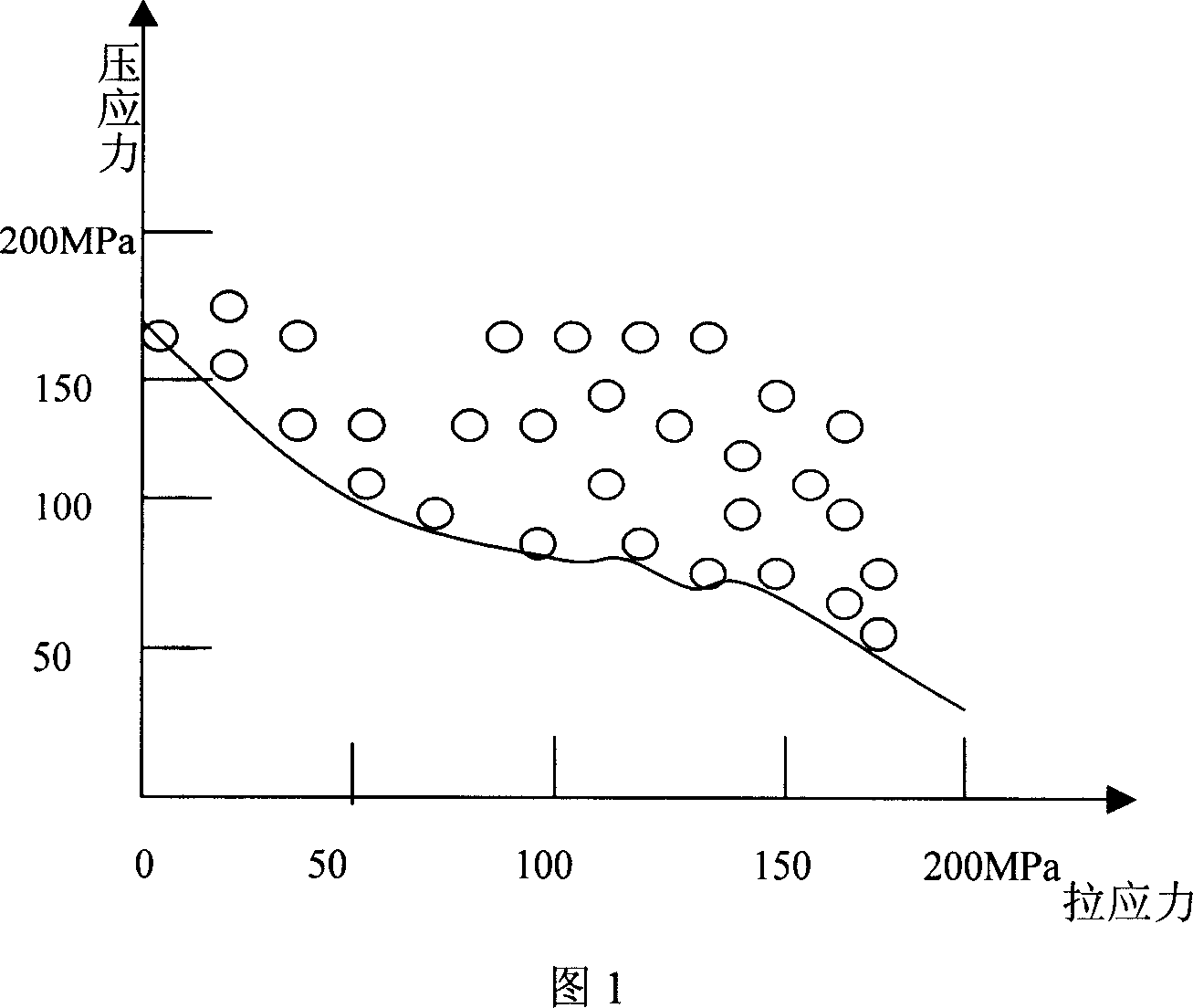

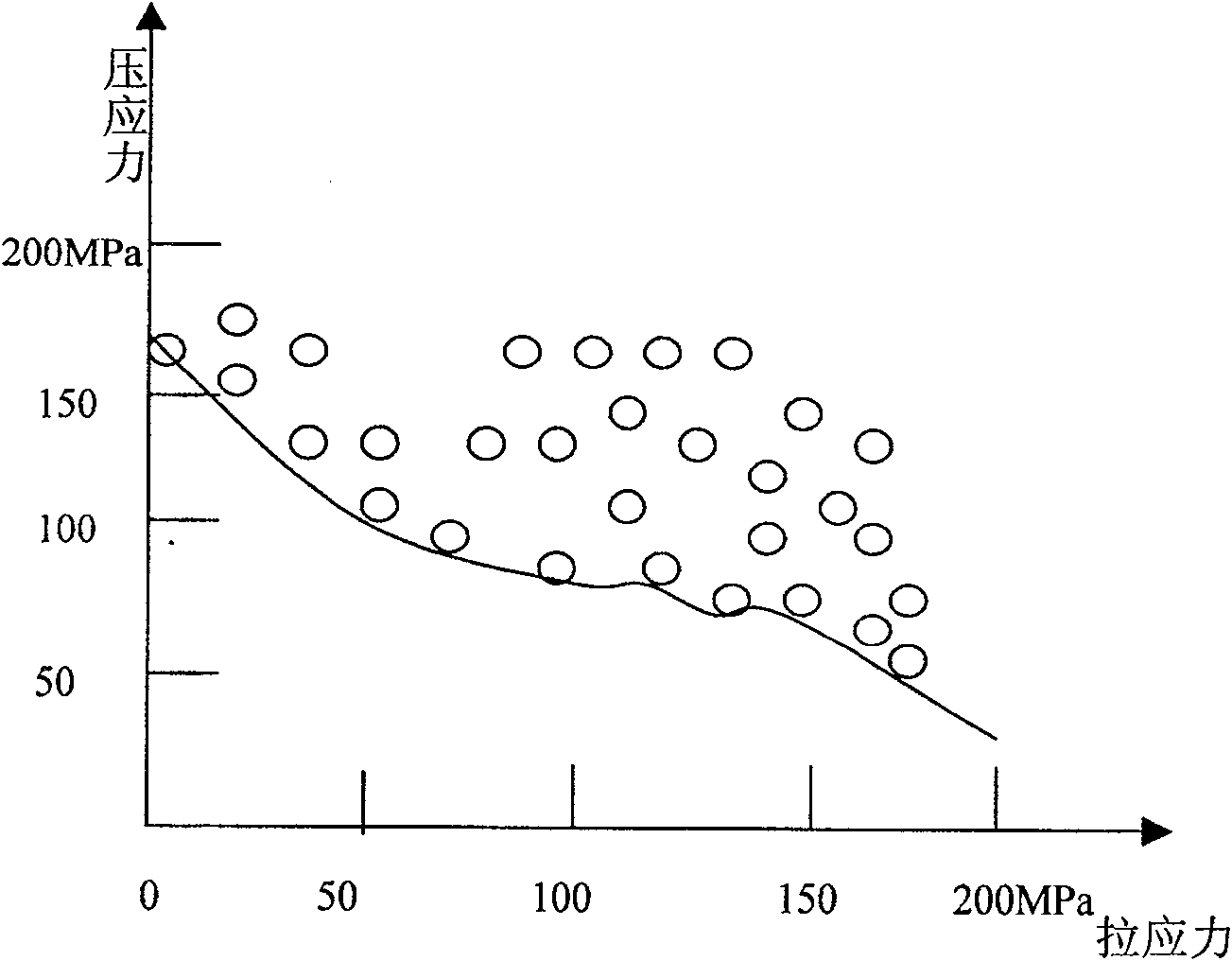

Method for determining quality of coat

InactiveCN100552426CEvaluation qualityUsing mechanical meansStrength propertiesCoated surfaceSystem integration

The invention discloses a method for judging the comprehensive performance of coating quality, which comprises the following steps: 1) conducting conventional plastic deformation tests such as unidirectional tension or compression on a test piece on a tension-compression testing machine in a test system; 2) when stretching or compress to a certain extent, carry out load preservation, and measure the cross-sectional area of the sample; 3) through the indentation tester integrated in the system, perform semi-automatic multi-point vertical compressive stress on the coating surface of the parallel section of the specimen while maintaining the load 4) After the indentation instrument is finished working, the system automatically removes the tensile or compressive load, and judges and records the tensile or compressive stress at the coating failure point and the vertical compressive stress through the microscopic imaging equipment that comes with the system. stress. The invention obtains the failure mechanism relationship curve of the sample coating by carrying out tension or compression on the integrated test system while maintaining the load of the sample, and carrying out vertical compressive stress or frictional loading, so that it can be comprehensive and practical. To evaluate the surface coating quality of materials.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com