Method and device for monitoring a joining seam during joining by means of a laser beam

A laser radiation, laser technology, applied in laser welding equipment, welding equipment, arc welding equipment and other directions, can solve the problems of difficult detection, poor connection and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In the respective figures, components and elements corresponding to each other are provided with the same reference numerals.

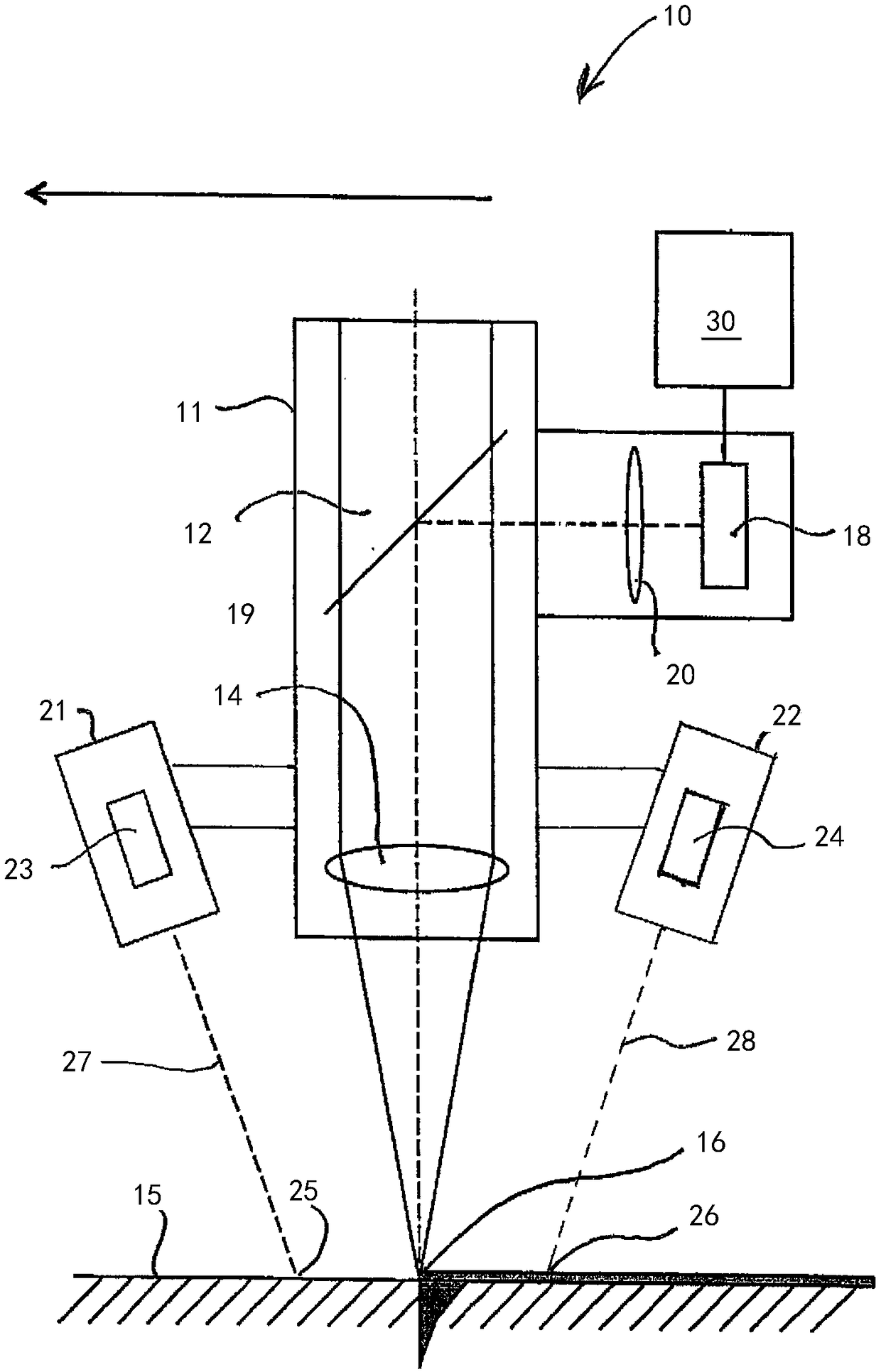

[0049] Such as figure 1 As shown, the laser processing head 10 has a housing 11 through which a processing laser beam 12 is guided and which is focused by means of a focusing lens 14 on a workpiece 15 . The focal point or focal point 16 is in this case located on the workpiece surface, or close to the workpiece surface at a distance above or below the workpiece surface, depending on the requirements of the desired weld, and melts the workpiece material to weld two sheets or the like together. In this case, the vapor capillary is usually formed in the region of the laser focal point 16, that is to say at the so-called tool center point (TCP), which is also referred to as the welding hole and is located in the processing area. at the center of. A camera 18 is arranged to observe the weld hole or puddle, said camera receiving process radiation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com