Hanging strip type cathode array structure panel display device and its production technique

A technology of flat panel display and array structure, which is applied in cold cathode manufacturing, discharge tube cold cathode, electrode system manufacturing, etc., to achieve the effect of improving the production success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

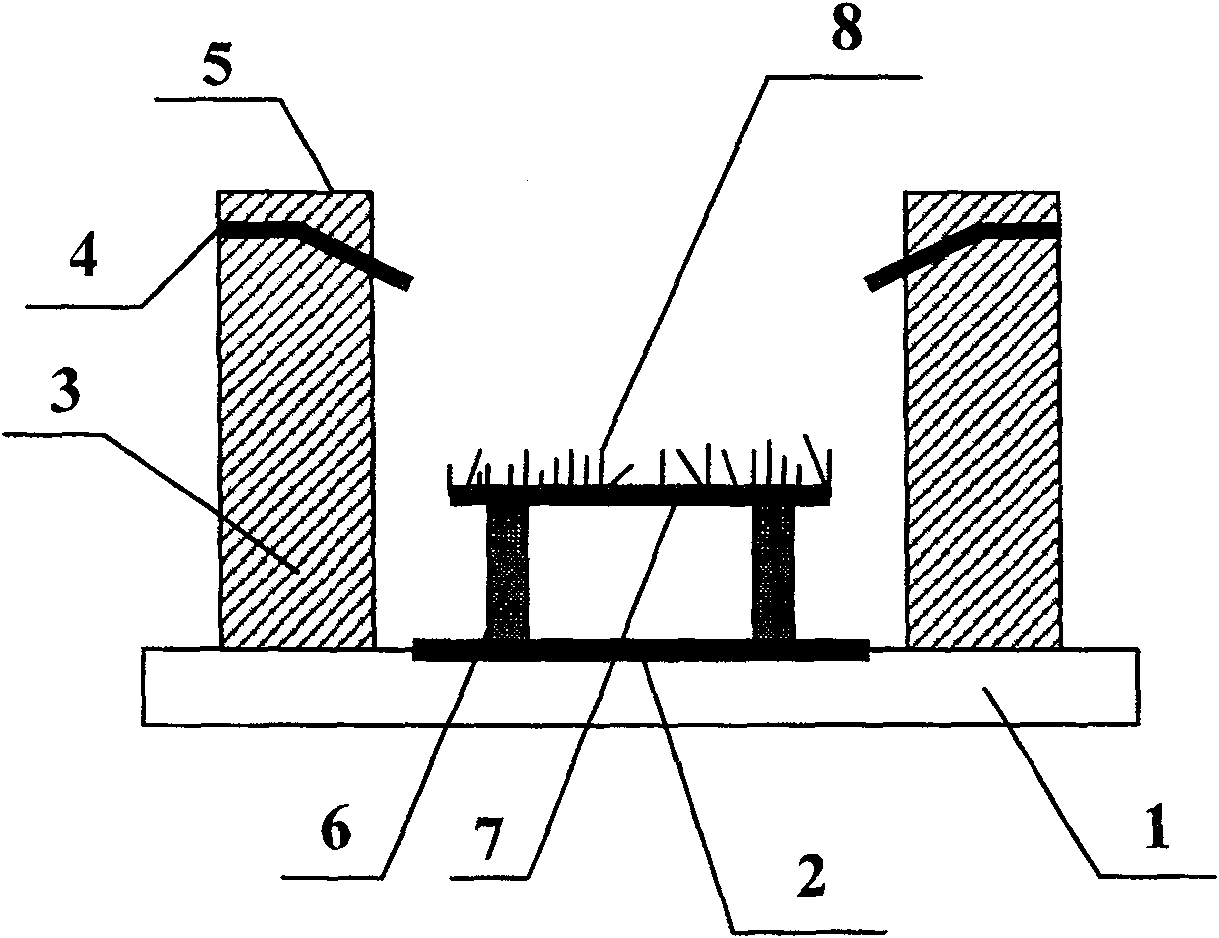

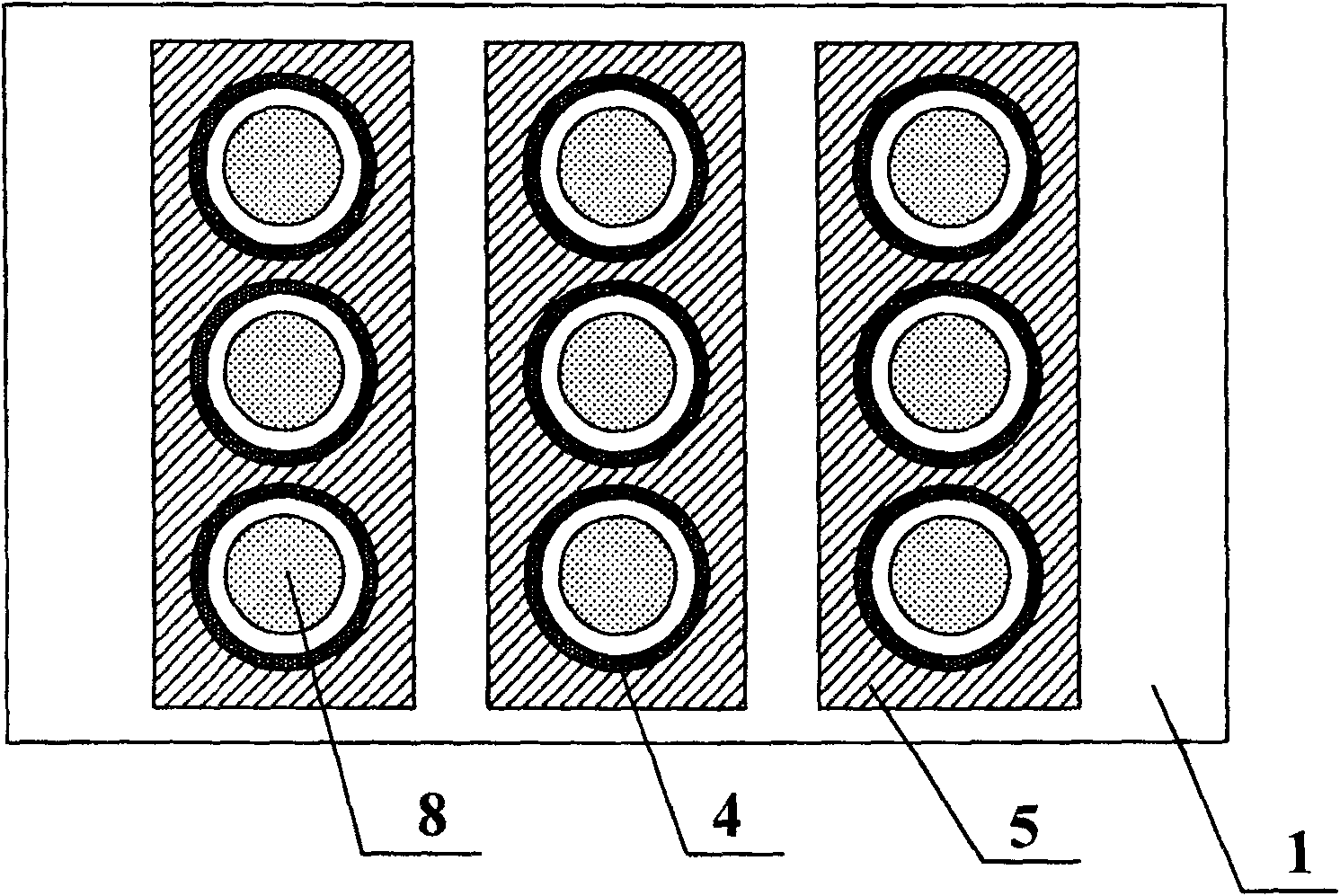

[0041] Described a kind of flat panel display with suspended strip type cathode array structure, comprises the airtight vacuum cavity that is made of anode glass panel 9, cathode glass panel 1 and surrounding glass frame 14; An anode conductive layer is arranged on the anode glass panel 10 and the phosphor layer 12 prepared on the anode conductive layer; there are control grid 4, carbon nanotubes 8 and suspended strip cathode array structure on the cathode glass panel; supporting wall structure 13 and getter accessory element 15.

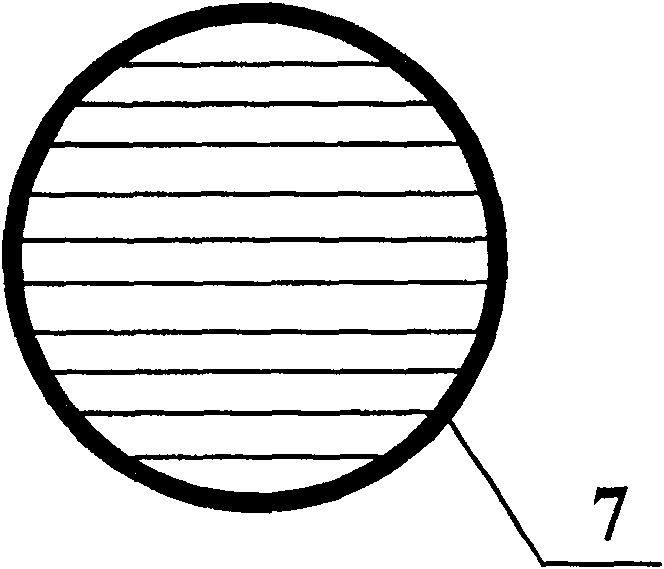

[0042] The suspended strip type cathode array structure includes a cathode glass panel 1, a cathode lead layer 2, a gate booster layer 3, a gate lead layer 4, a grid cover layer 5, a cathode booster layer 6, a transition layer 7 and carbon nanotubes 8 Cathode part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com