Hyperfiltration reverse- rinsing water recovery processing method and device thereof

A technology for recycling and backwashing water, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. It can solve the problems of low recovery efficiency and achieve high recovery efficiency , saving water resources, good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

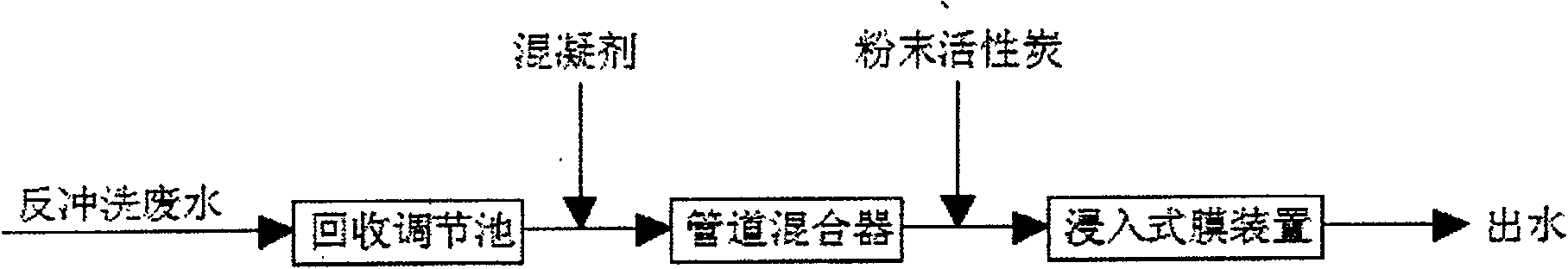

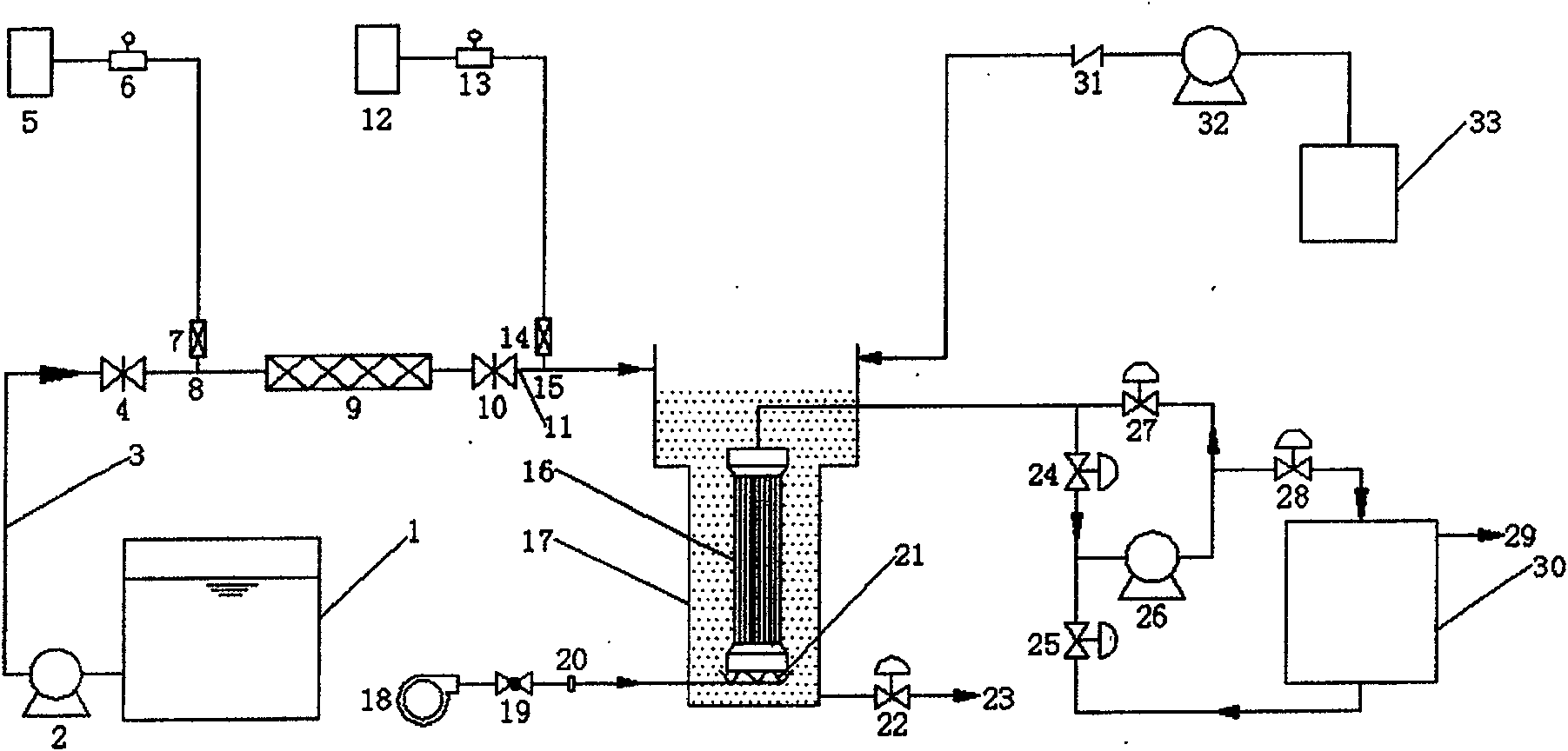

Embodiment 1

[0026] An experiment was carried out on the backwash water of an ultrafiltration membrane. The water quality conditions were: water temperature 12.3-14.2°C, pH 7.81-7.95, turbidity 5.21-8.14NTU, permanganate index 4.76-7.21mg / L, UV 254 0.042~0.045cm -1 . The membrane backwash water first enters the recovery adjustment tank, and then the amount of FeCl is added to the backwash water discharged from the recovery adjustment tank. 3 Coagulant FeCl calculated as 15mg / L 3 , the wastewater then enters the pipeline mixer for mixing, and the outlet water of the pipeline mixer enters the membrane tank of the submerged membrane device after adding 10mg / L powdered activated carbon. The suction negative pressure in the inner cavity passes through the membrane to obtain ultrafiltration backwash water and recover the effluent. The filtration cycle of the submerged membrane device is 20 minutes. After the filtration cycle is over, backwashing is performed, and one round of backwashing is p...

Embodiment 2

[0028] An experiment was carried out on the backwash water of an ultrafiltration membrane. The water quality conditions were: water temperature 13.2-14.8°C, pH 7.82-7.94, turbidity 6.34-7.56NTU, permanganate index 5.83-6.25mg / L, UV 254 0.044~0.057cm-1 . Membrane backwash water first enters the recovery adjustment tank, and then the amount of FeCl is added to the backwash water discharged from the recovery adjustment tank. 3 Coagulant FeCl calculated as 20mg / L 3 , the waste water then enters the pipeline mixer for mixing, and the outlet water of the pipeline mixer enters the membrane tank of the submerged membrane device after adding 15mg / L powdered activated carbon. The suction negative pressure in the inner cavity passes through the membrane to obtain ultrafiltration backwash water and recover the effluent. The filtration period of the submerged membrane device is 25 minutes. After the filtration period, backwashing is performed, and two rounds of backwashing are performed ...

Embodiment 3

[0030] An experiment was carried out on the backwash water of an ultrafiltration membrane. The water quality conditions were: water temperature 13.1-14.6°C, pH 7.76-8.02, turbidity 6.47-9.21NTU, permanganate index 5.63-7.12mg / L, UV 254 0.041~0.062cm -1 . Membrane backwash water first enters the recovery adjustment tank, and then the amount of FeCl is added to the backwash water discharged from the recovery adjustment tank. 3 Coagulant FeCl calculated as 20mg / L 3 , the wastewater then enters the pipeline mixer for mixing, and the outlet water of the pipeline mixer enters the membrane tank of the submerged membrane device after adding 30mg / L powdered activated carbon. The suction negative pressure in the inner cavity passes through the membrane to obtain ultrafiltration backwash water and recover the effluent. The filtration period of the submerged membrane device is 25 minutes. After the filtration period, backwashing is performed, and two rounds of backwashing are performed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com