System for injecting pasty, semipasty or liquid waste into an incineration furnace

An injection system, garbage technology, applied in the direction of burning block fuel and liquid fuel, burning block fuel and gaseous fuel, burning liquid fuel and gaseous fuel, etc., can solve the problem of interfering with furnace operation, combustion Stop and other problems, to achieve the effect of optimized consumption, good combustibility, and large specific area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

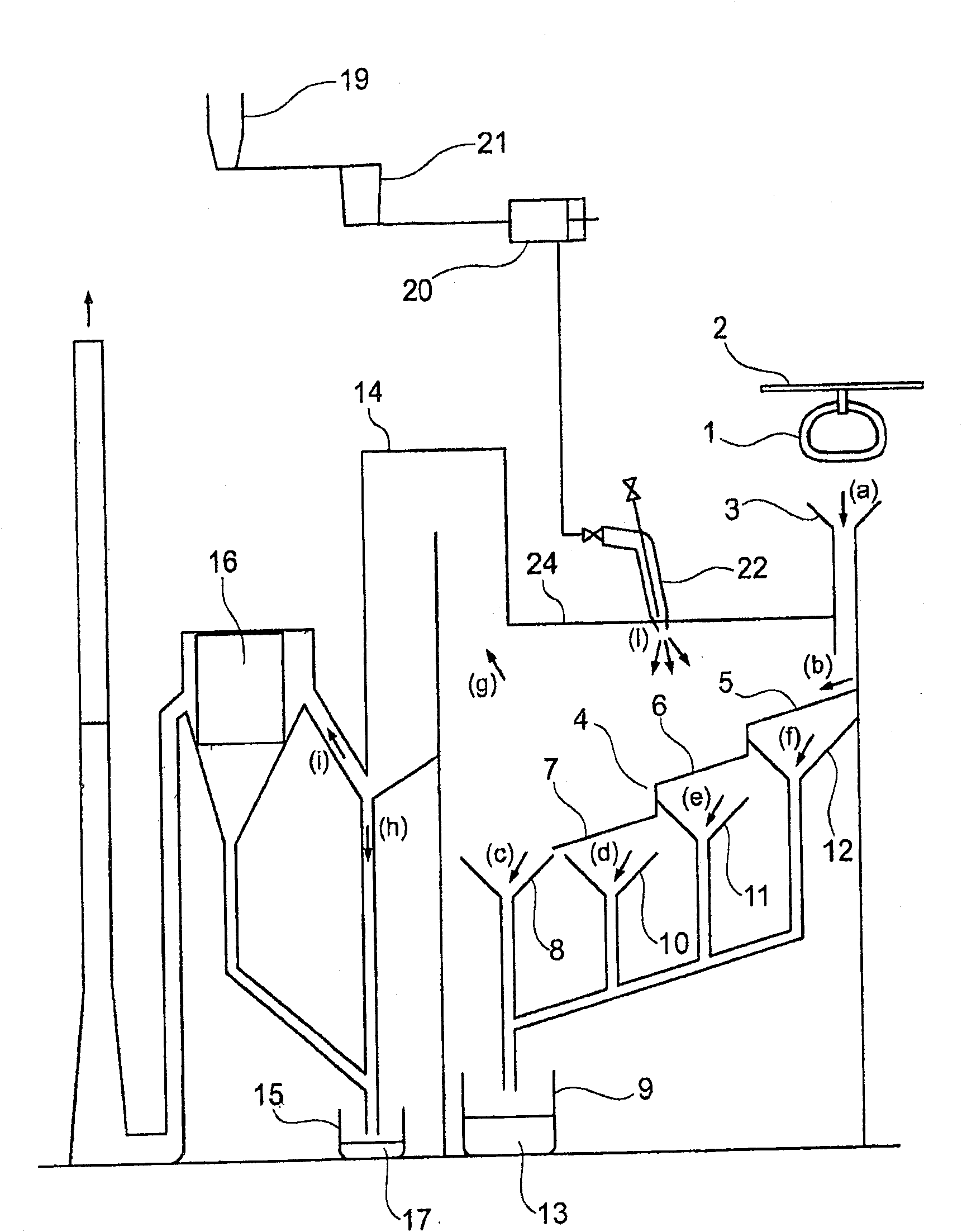

[0069] [69] cf. figure 1 , the shown incinerator is actually a traditional MSW incinerator added with an injection system in accordance with the present invention.

[0070] [70] A grab bucket 1 fixed to an overhead crane 2 can grab household waste into a storage tank (not shown) and dump (a) them into a feed hopper 3 . These household wastes arrive at (b) an incineration bed 4 .

[0071] [71] In this conventional example, the incineration bed 4 consists of three successive zones (or steps), each zone formed by rollers:

[0072] [72] - a drying zone 5 for domestic waste to facilitate their subsequent combustion;

[0073] [73] - a combustion zone 6; and

[0074] [74] - An end zone 7.

[0075] [75] After the domestic waste passes through the incineration bed, the slag 13 is obtained, and the slag 13 is collected in a bucket 9 (or other storage device) through a discharge hopper 8 for discharge.

[0076] [76] Further discharge hoppers 10, 11, 12 may also be provided below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com