Drop head assembly of droplet pill machine

A dripping pill machine and dripper technology, which is applied to special packaging objects, solid materials, packaging, etc., can solve the problems of restricting the adjustment of the diameter of the dripping pill, the unstable operation of the quantitative pump, and the irregular shape of the opening, etc., to achieve good consistency , The process of dropping pills is stable and reliable, and the effect of relieving inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof, but it does not limit the claims of the present invention.

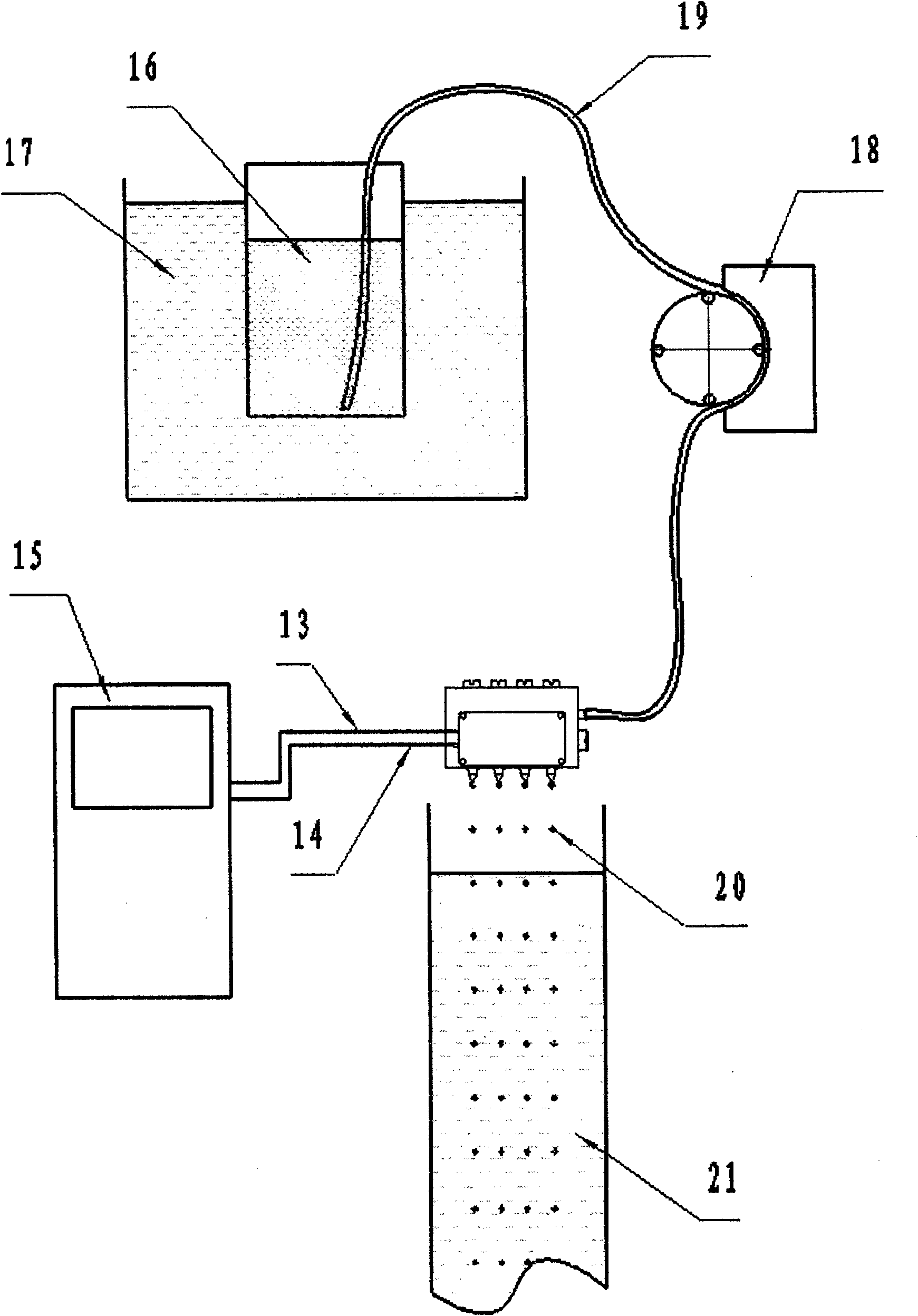

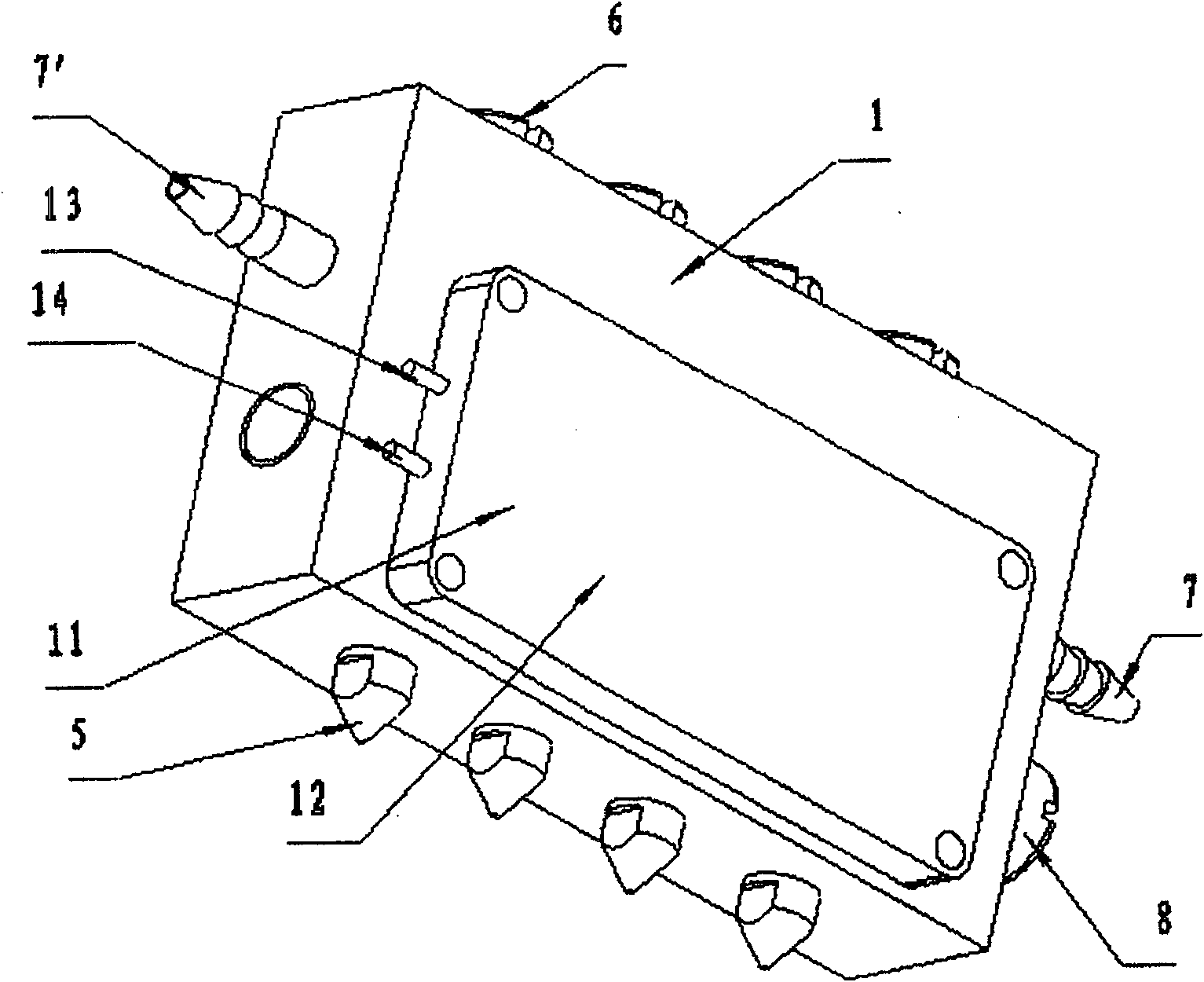

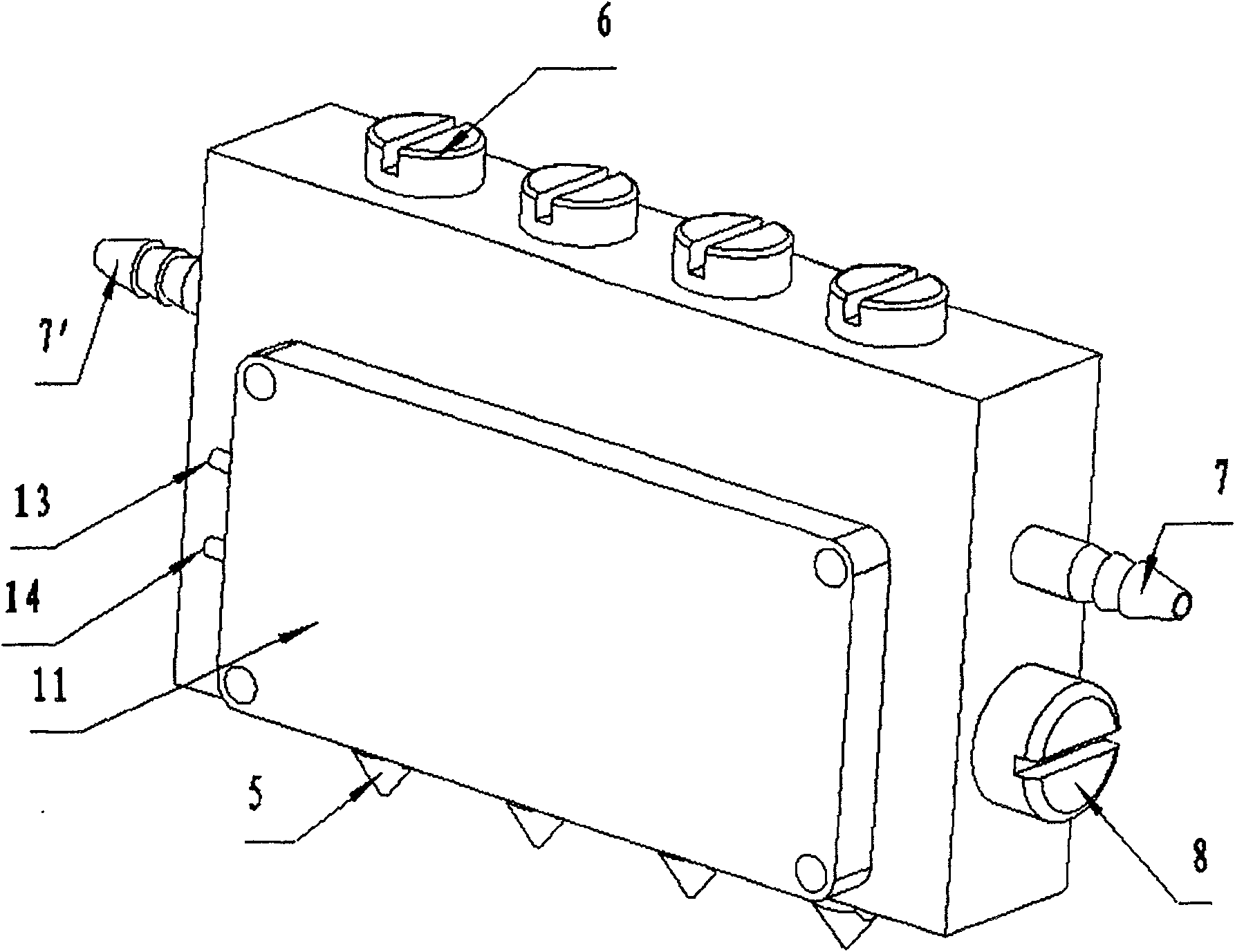

[0025] A kind of dropper assembly of dripping pill machine designed by the present invention (hereinafter referred to as dripper, see Figure 2-7 ), which is characterized in that it includes a housing 1, the housing 1 is punched with two or more through holes 2 parallel to each other for liquid communication, and each of the through holes 2 is covered by the first blind hole perpendicular to it 3 communicated, and a second blind hole 4 parallel to the first blind hole 3 is opened between the first blind hole 3 and the outlet of the housing at one end of each through hole 2; each through hole 2 The outlet of one end of the casing is equipped with a drip nozzle 5, and the outlet of the other end of the casing is equipped with a head 6; the opening of the casing of the first blind hole 2 is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com