Rocker arm type landing ladder for releasing celestial body detecting vehicle

A planetary exploration vehicle and rocker-type technology, which is applied in the direction of motor vehicles, space navigation equipment, space navigation aircraft, etc., can solve the problems of large size and unfavorable stable release of the detection vehicle, and achieve small size, which is conducive to smooth release, The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

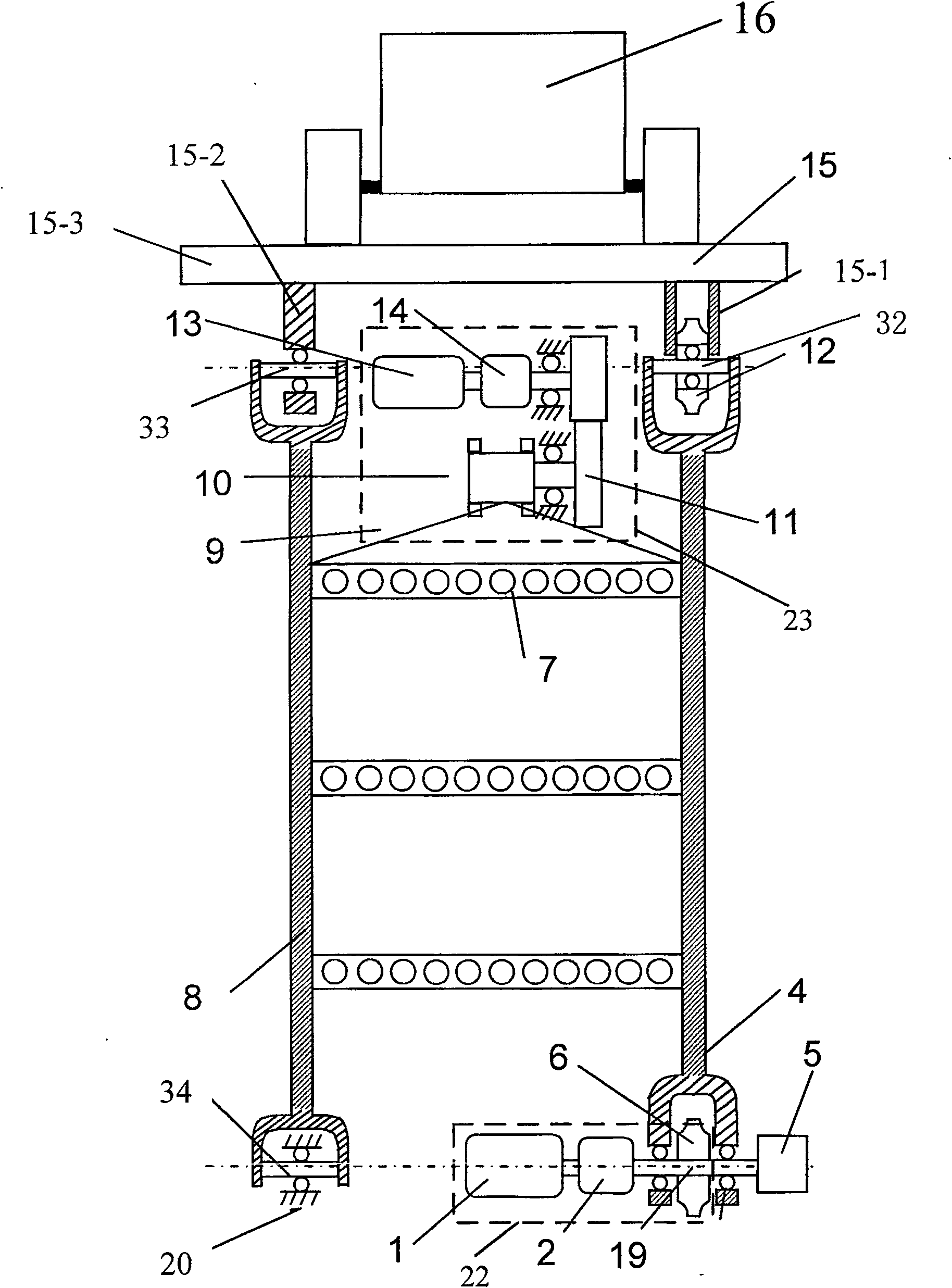

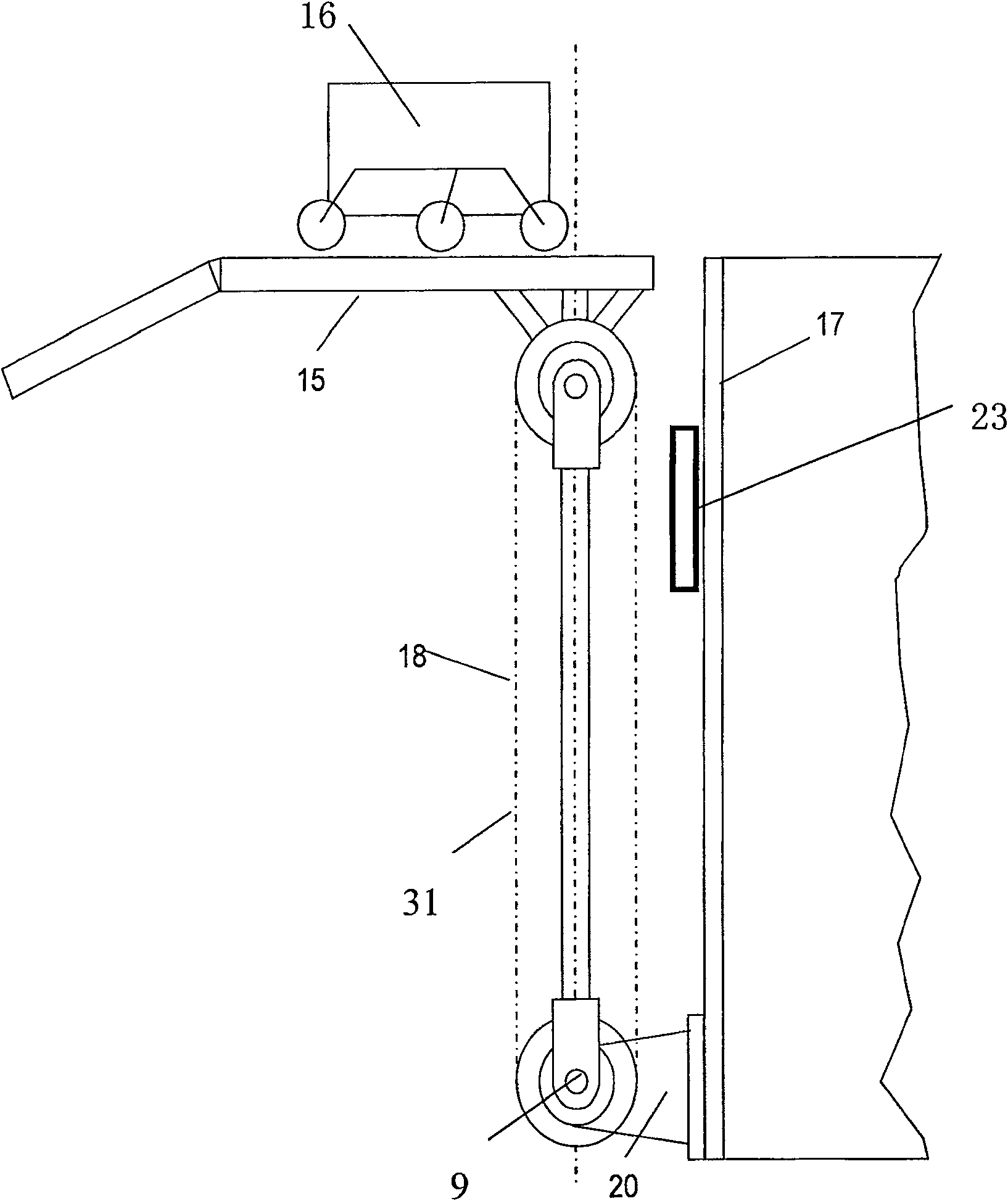

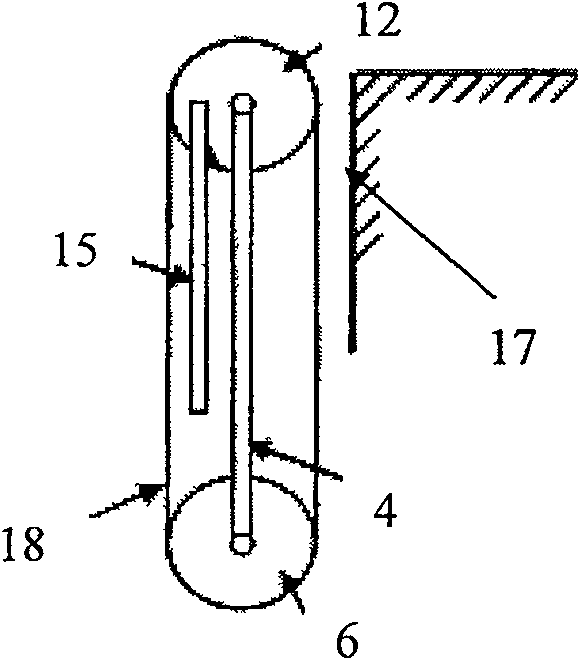

[0007] Specific implementation mode one: combine figure 1 with figure 2 This embodiment is described. The rocker-arm type landing ladder for planetary exploration vehicle release in this embodiment includes the main rocker arm 4, the vehicle-carrying platform 15, and the base 20. The landing ladder also includes a transmission mechanism 31, and the vehicle-carrying platform is deployed to drive Component 22, detection car release control component 23, the transmission mechanism 31 is made up of the first sprocket or pulley 6, the second sprocket or pulley 12, transmission chain or transmission belt 18, drive shaft 19, driven shaft 32, the The vehicle-carrying platform deployment drive assembly 22 is composed of a drive motor 1, a harmonic reducer 2, and a backstop 5, and the detection vehicle release control assembly 23 includes a motor 13, a reducer 14, a reel 10, and a rope 9; The transmission mechanism 31 is positioned under the vehicle-carrying platform 15, and the secon...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 with figure 2 To illustrate this embodiment, the probe vehicle release control assembly 23 in this embodiment further includes a gear pair 11 , and the output shaft of the reducer 14 is connected to the reel 10 through the gear pair 11 . The reel can be positioned at the center of the whole mechanism in a small space through the change of the first-stage gear pair to ensure a more balanced force on the rocker arm. If the design space is sufficient, the reel can also be directly connected to the output of the reducer. on axis. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 with figure 2 Describe this embodiment, the landing ladder in this embodiment also includes a secondary rocker arm 8, a first secondary rocker shaft 33, and a second secondary rocker shaft 34, and the first secondary rocker shaft 33 is mounted on the vehicle through a bearing On the second support member 15-2 on the platform 15, the upper end of the auxiliary rocker arm 8 is hinged to the two ends of the first auxiliary rocker arm shaft 33, and the lower end of the auxiliary rocker arm 8 is connected to the two ends of the second auxiliary rocker arm shaft 34. The ends are hinged, and the second auxiliary rocker arm shaft 34 is installed on the support 20 by bearings. The end of the rope 9 is divided into two segmented ropes, and the two segmented ropes are fixedly connected with the main rocker arm 4 and the auxiliary rocker arm 8 respectively. The auxiliary rocker arm 8 plays a supporting role, so that the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com