PWM rectifying system based on IGCT and its working method

A rectification system, the said technology, is applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., which can solve the problem of power device current carrying, small voltage withstand capacity, and unsuitable rectification system for large power grids. , AC side power factor drop and other issues, to achieve the effect of improving current carrying capacity, easy to understand software programming, and improving power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

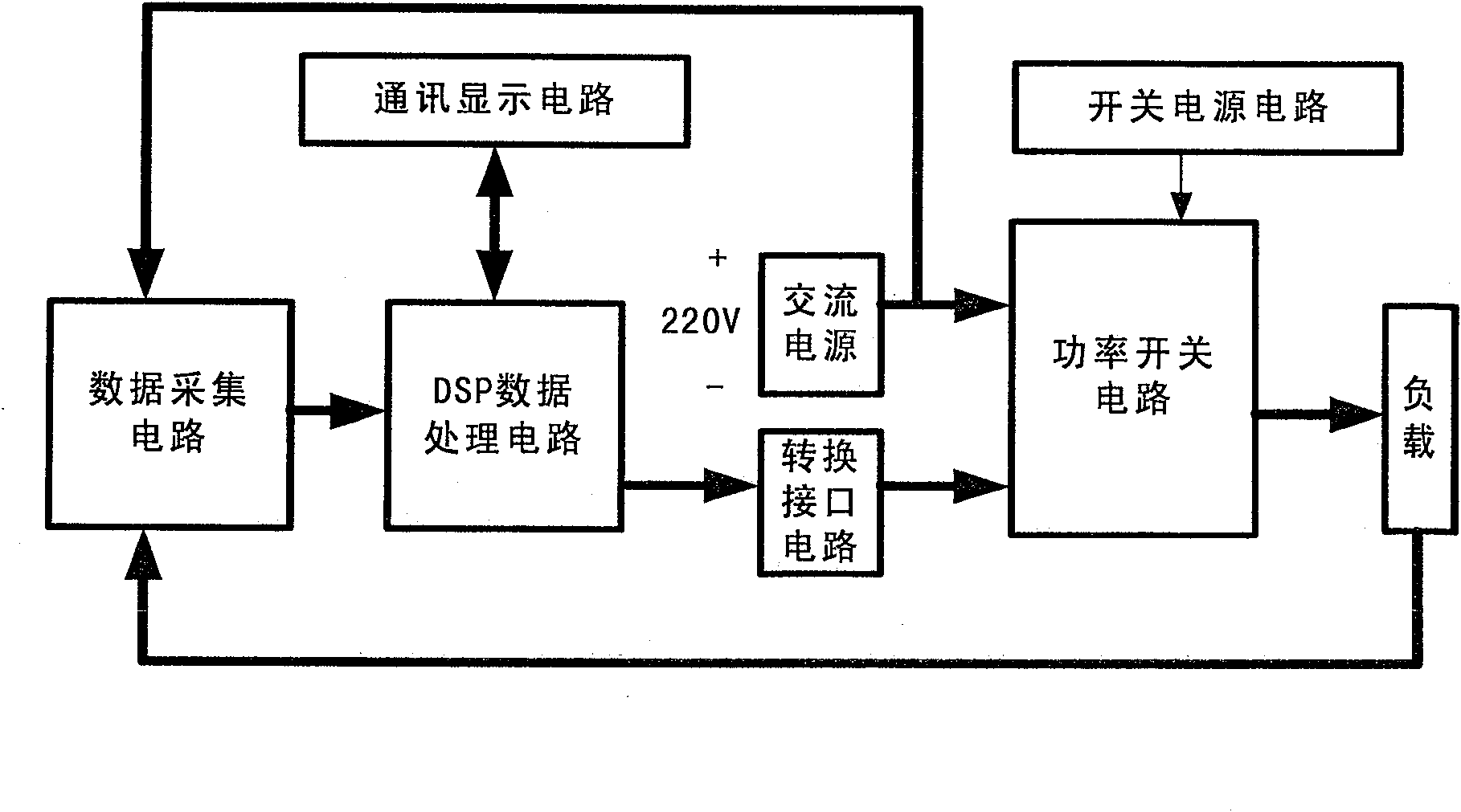

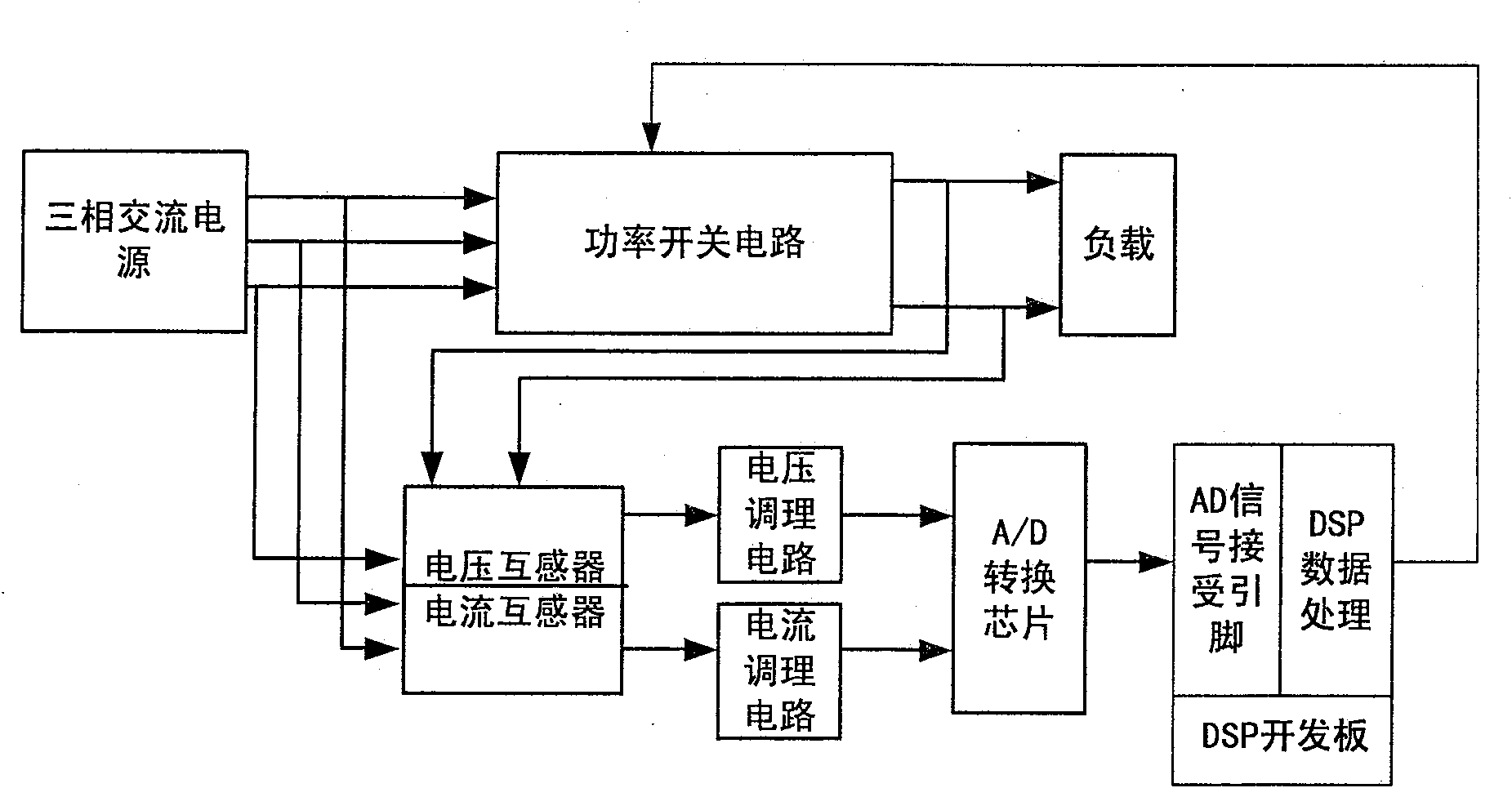

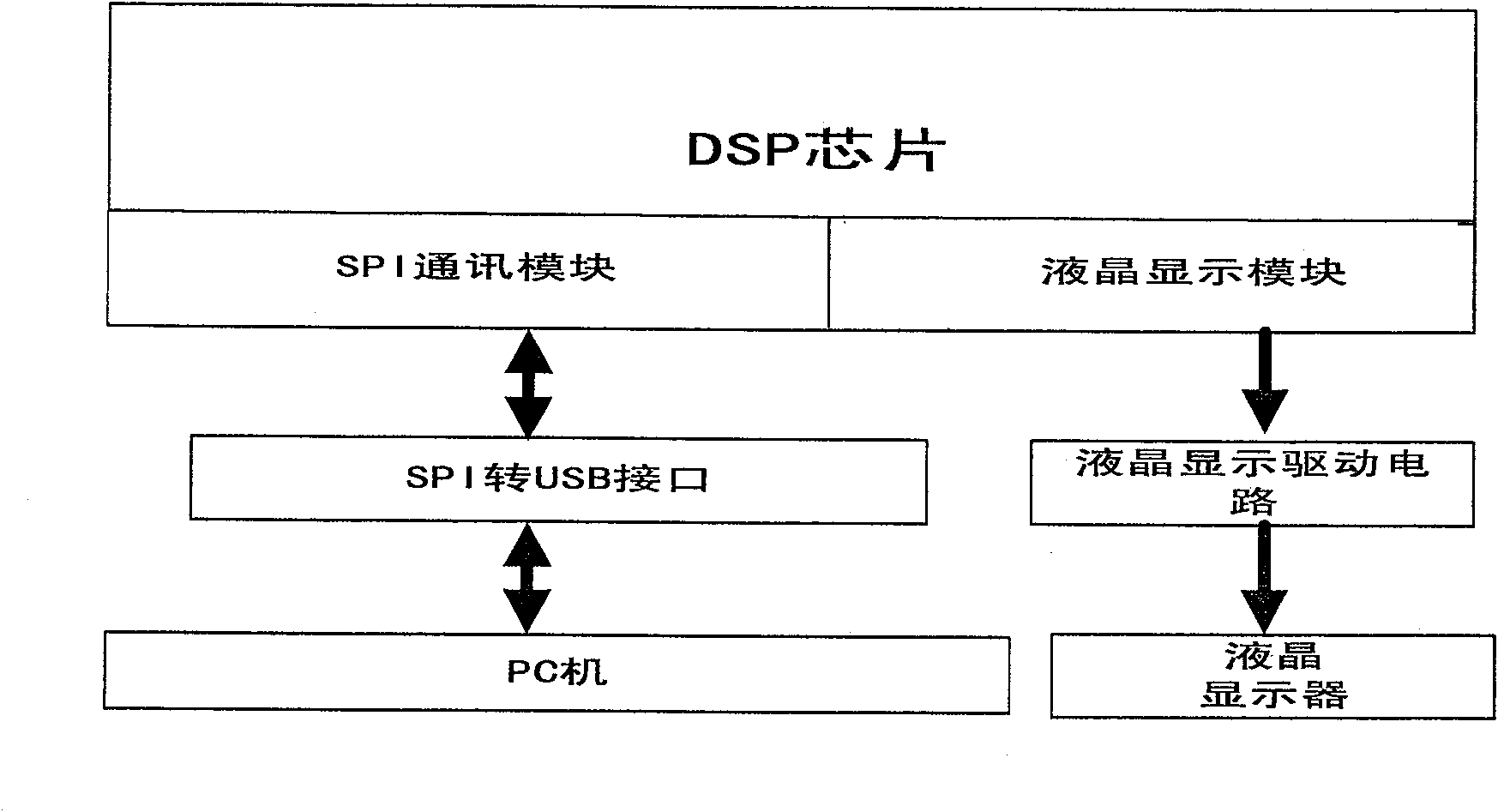

[0024] A PWM rectification system based on the IGCT of GVC733CE is characterized in that it comprises a data acquisition circuit, a TMS320F2812 DSP data processing circuit, a conversion interface circuit, a power switch circuit, a switching power supply circuit and a communication display circuit (see figure 1 ); said data acquisition circuit input end is connected to the AC power supply of load end and 220V respectively, its output end is connected to the input end of DSP data processing circuit, and the output end of TMS320F2812DSP data processing circuit is connected to the input end of conversion interface circuit; The output end of the conversion interface circuit is connected to the input end of the power switch circuit, the switching power supply circuit supplies power to the power switch circuit, and the output end is connected to the power input end of the power switch circuit; the input end of the communication display circuit is connected to To the corresponding outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com