Gas-liquid separation heat exchanging gas-returning regulation station

A gas-liquid separation and conditioning station technology, applied in refrigeration and liquefaction, lighting and heating equipment, coolers, etc., can solve problems such as destroying the atmospheric ozone layer, and achieve the effects of low dry consumption, simple production and stable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

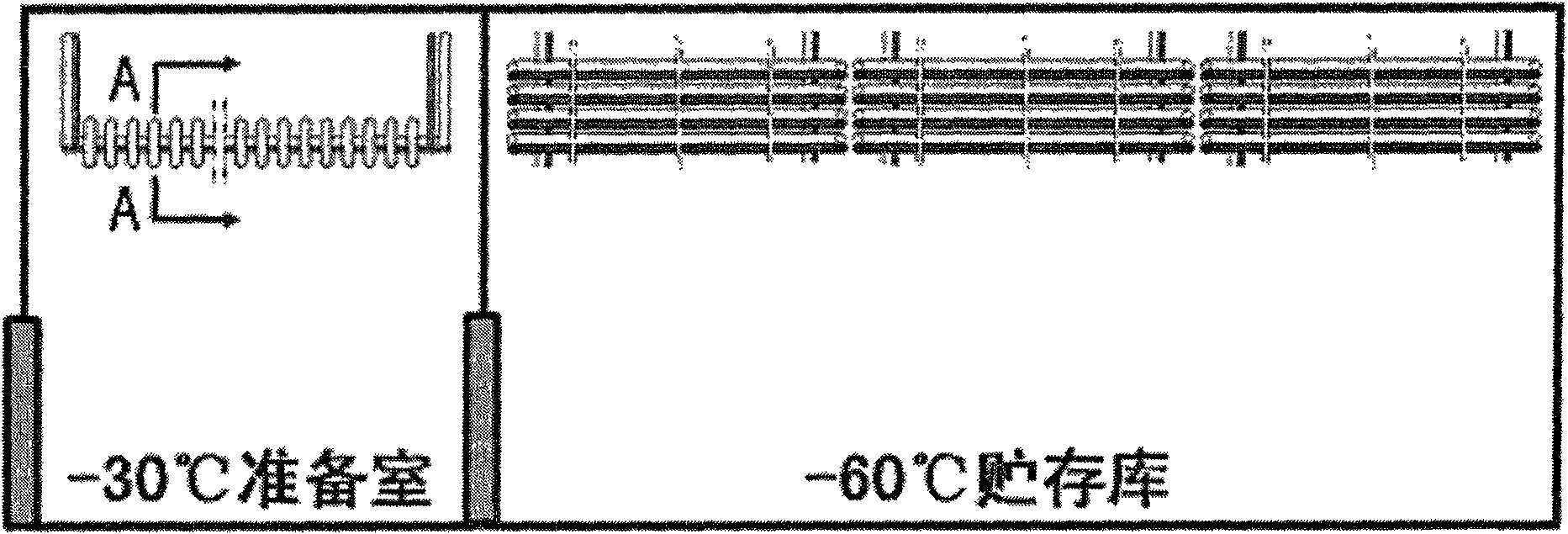

[0030] There are three types of tuna storage temperatures in the world: -50°C, -55°C, and -60°C. According to the most advanced international tuna storage temperature of -60°C, R717 is used as the refrigerant for -60°C tuna storage. The insulation layer around the ceiling and the ground of the -60°C tuna storage warehouse is made of polyurethane with a thickness of 450mm. In order to prevent the polyurethane from cracking at -60°C, the thickness of the polyurethane is sprayed at 50mm each time. After cooling and shrinking, spray another The first floor; the cold storage adopts a double-chamber structure, the outside is a preparation room at -30°C, the inside is a storage room at -60°C, and the temperature difference is -30°C.

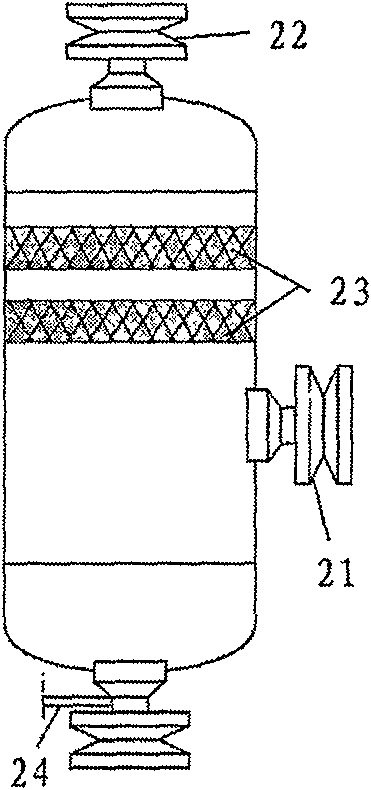

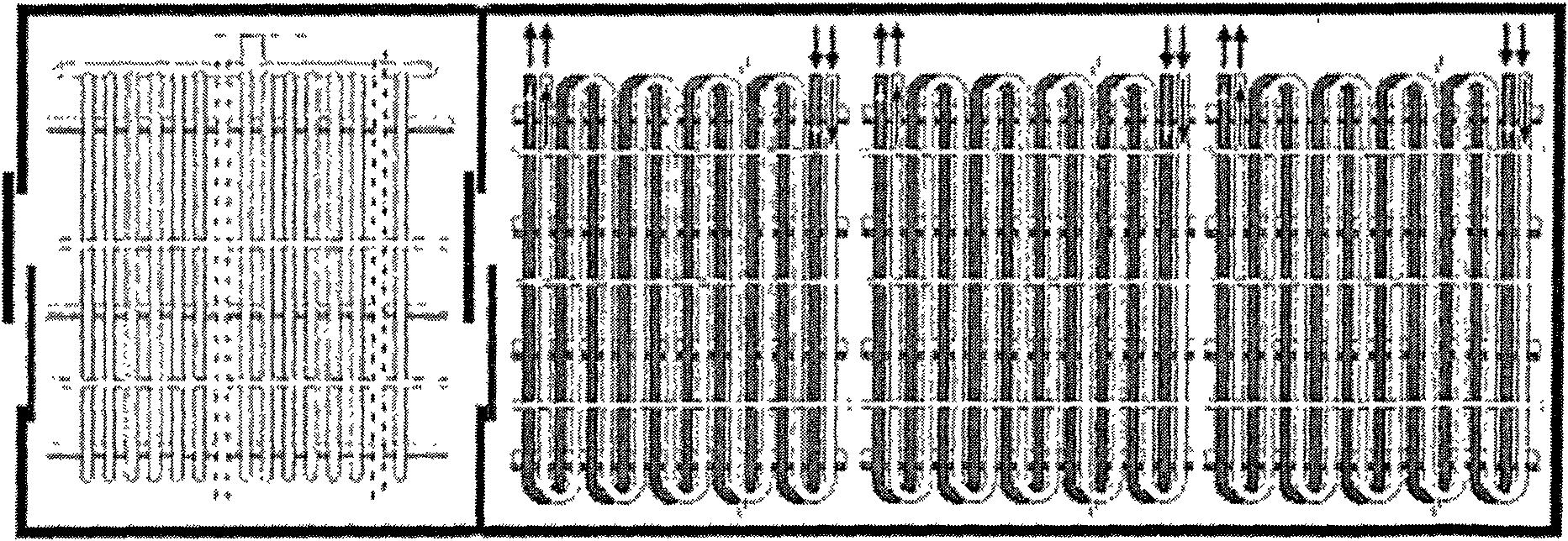

[0031] (1) -60°C working medium (ammonia) ceiling pipe

[0032]R717 refrigeration system is adopted to achieve low temperature storage at -60°C. We designed -60°C ceiling pipes, which changed the traditional manufacturing process. The horizontal diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com