Component for motor vehicle

A component and automobile technology, applied to vehicle parts, upper structure, upper structure sub-assembly, etc., can solve the problems of temperature rise, damage to plastics, etc., and achieve the effect of bearing mechanical load, high mechanical load and high connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] FIG. 1 shows, in cross-section, a metal beam 1 with a known operating principle, which forms the body of a component according to the invention, which will be described in more detail below. The crossbeam 1 , also referred to as the dashboard support, is arranged as a support part of the body structure between the A-pillars of the vehicle and forms a mechanical connection with other components, such as the airbag housing.

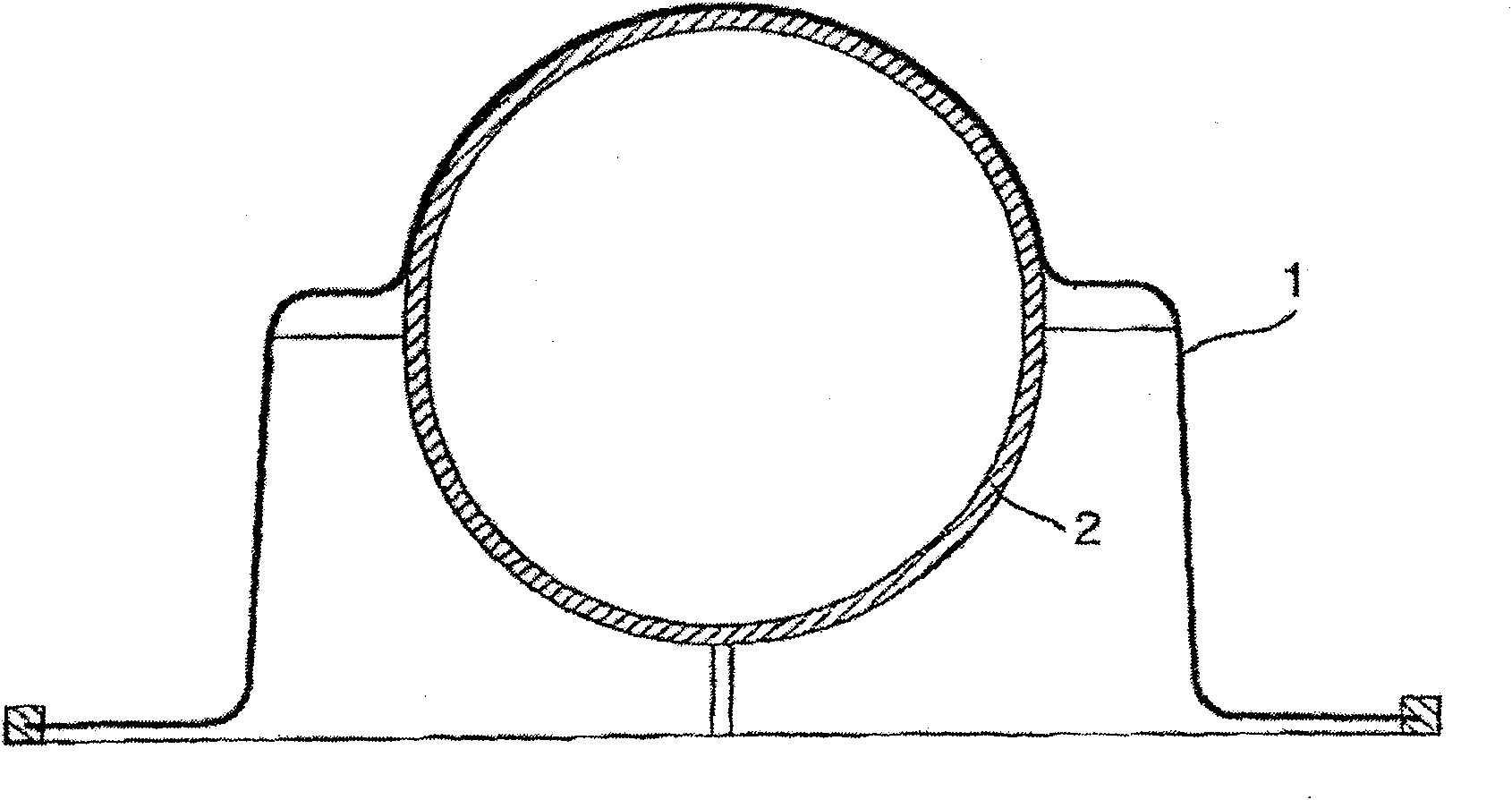

[0034] The same principle of operation is known, for example, in DE 10064522 A1, according to the arrangement of FIG. 2 , with a cross member 1 having a circular cross-section duct or vent pipe 2 which is produced from plastic by injection moulding. Ventilation ducts 2 , which at least slightly increase the stability of the cross member 1 , extend along the cross member 1 , so that the supply air is distributed in the transverse direction of the vehicle.

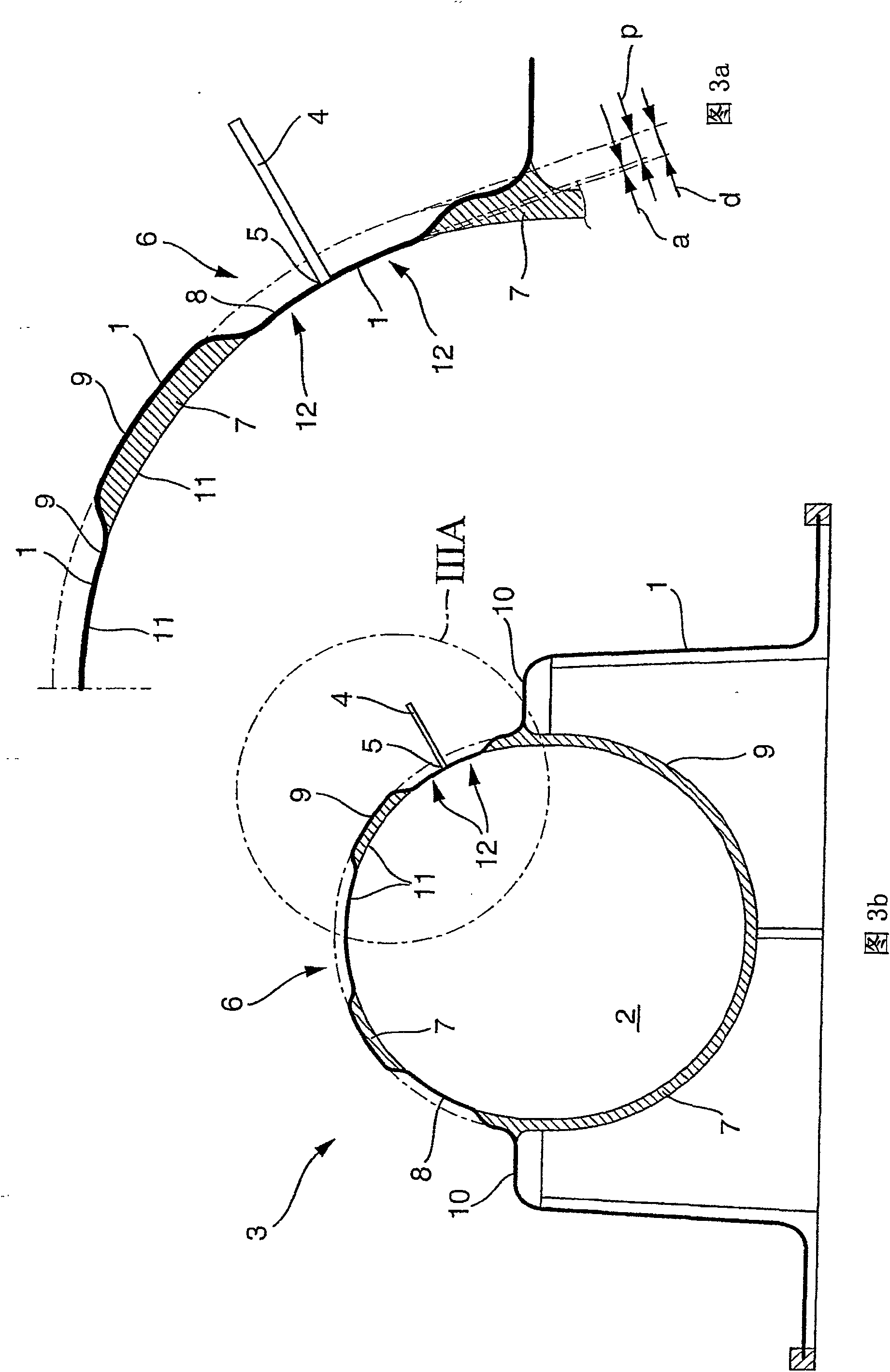

[0035] exist Figure 3a and 3b In , the structural principle of the component 3 of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com