Connected vessels type steam pocket water level sampling and measuring device and method for deciding its geometric size

A technology for measuring device and drum water level, which is applied in the components of steam boilers, steam boilers, steam generation, etc., can solve problems such as affecting the popularization and application of new products, increasing the number of structural pipes, increasing the difficulty of operation and maintenance and fault diagnosis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

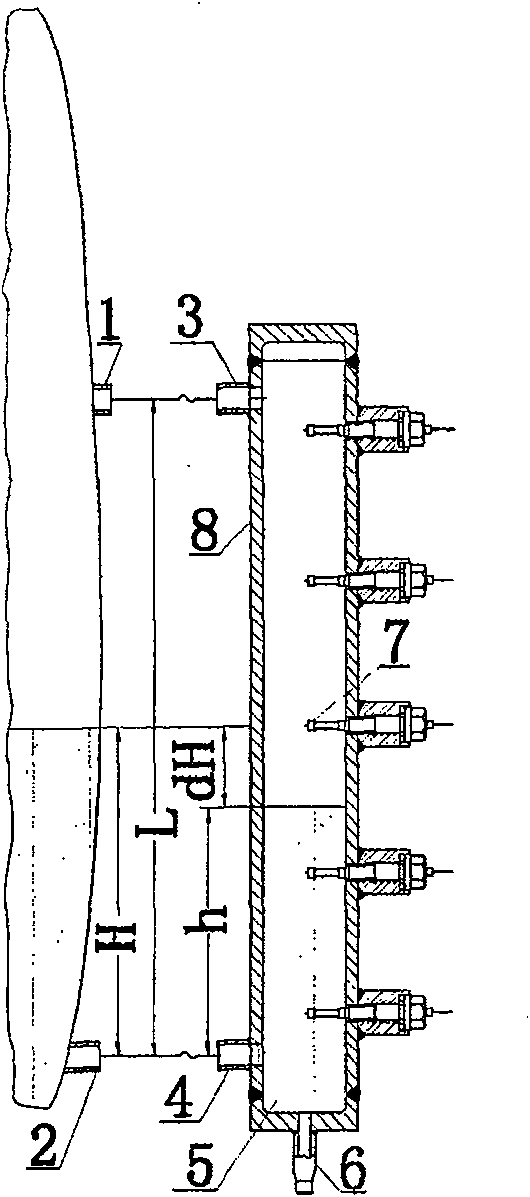

[0066] This example is attached figure 2 , the specific measuring device is an electric contact measuring cylinder. The additional steam chamber cylinder body 9 with horn constriction is welded to the extension section above the metering section cylinder body 8 , and the extension section has a steam communication pipe 3 . An electric contact electrode assembly 7 is installed on the cylinder body 8 of the metering section, a water connecting pipe 4 is provided at the bottom of the cylinder body 8 of the metering section, and a sewage discharge pipe 6 is provided at the bottom of the airtight container 5 .

no. 2 example

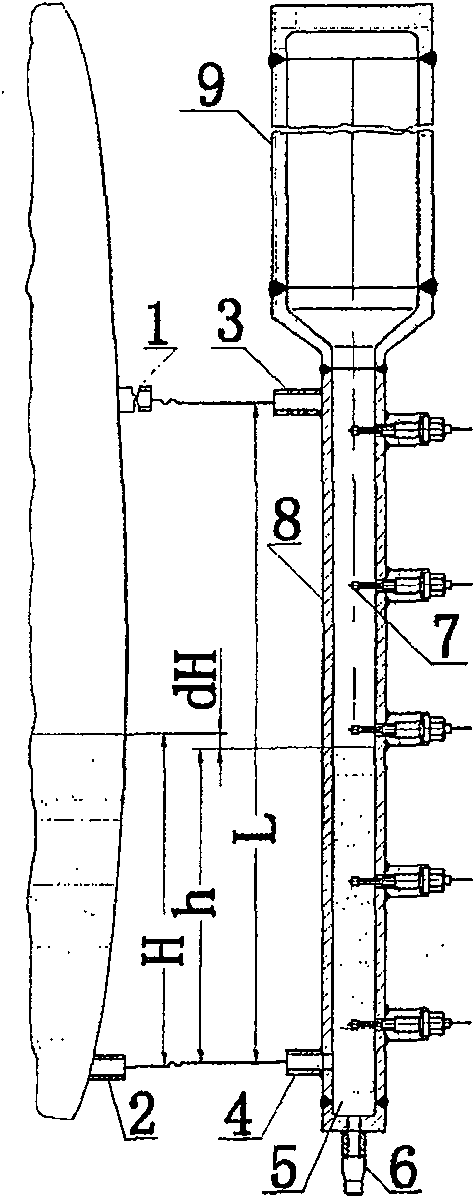

[0068] This example is attached image 3 , the specific measuring device is a magnetic float measuring cylinder. In this embodiment, the additional steam chamber cylinder 9 is welded to the extension section above the metering section cylinder 8 , and the metering section cylinder 8 has a steam sampling connecting pipe 3 and a water connecting pipe 4 above and below. There is a hollow cylindrical magnetic float 10 inside the cylinder body 8 of the metering section, which can float on the top of the water column, and the center of gravity of the magnetic float is at the bottom. A plurality of magnetic flaps 11 are installed outside the cylinder body 8 of the metering section, and the magnetic flaps can automatically turn over 180° when the magnetic float approaches to mark and display the water level. The extension section of the cylinder body 8 of the metering section is connected to the flange assembly 12, and the assembly can be disassembled to take out the magnetic float. ...

no. 3 example

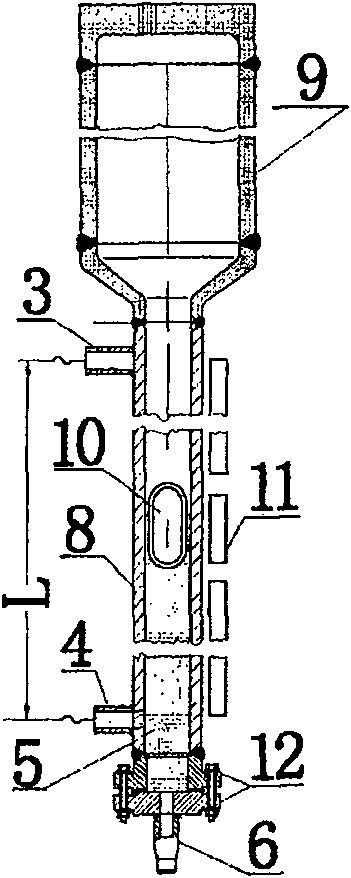

[0070] This example is attached Figure 4 , the specific measuring device is a capacitive measuring cylinder. The feature of the additional steam chamber cylinder body 9 in the present embodiment is the combined cylinder body of two steam chambers, and this combination is the extension section that the two steam chamber cylinder bodies are connected in parallel to the metering section cylinder body 8 by the pipeline, so, The surface area of the cylinder body of the additional steam chamber is the sum of the surface areas of the parts above the cylinder body 8 of the metering section. There are steam sampling connecting pipes 3 and water connecting pipes 4 on the top and bottom of the metering section cylinder body 8 . A flange 14 is welded on the top of the extension section above the cylinder body 8 of the metering section, and is connected with a flange capacitor assembly 15 . The insulated capacitor rod 13 in the flange capacitor assembly 15 is inserted into the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com