Intelligent environment-friendly jet molding equipment

An environmentally friendly, spray-molded technology, applied in the direction of architecture and building construction, can solve the problems of structural component restrictions, environmental pollution, waste of materials, etc., and achieve the effects of clean process production, environmental protection, and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

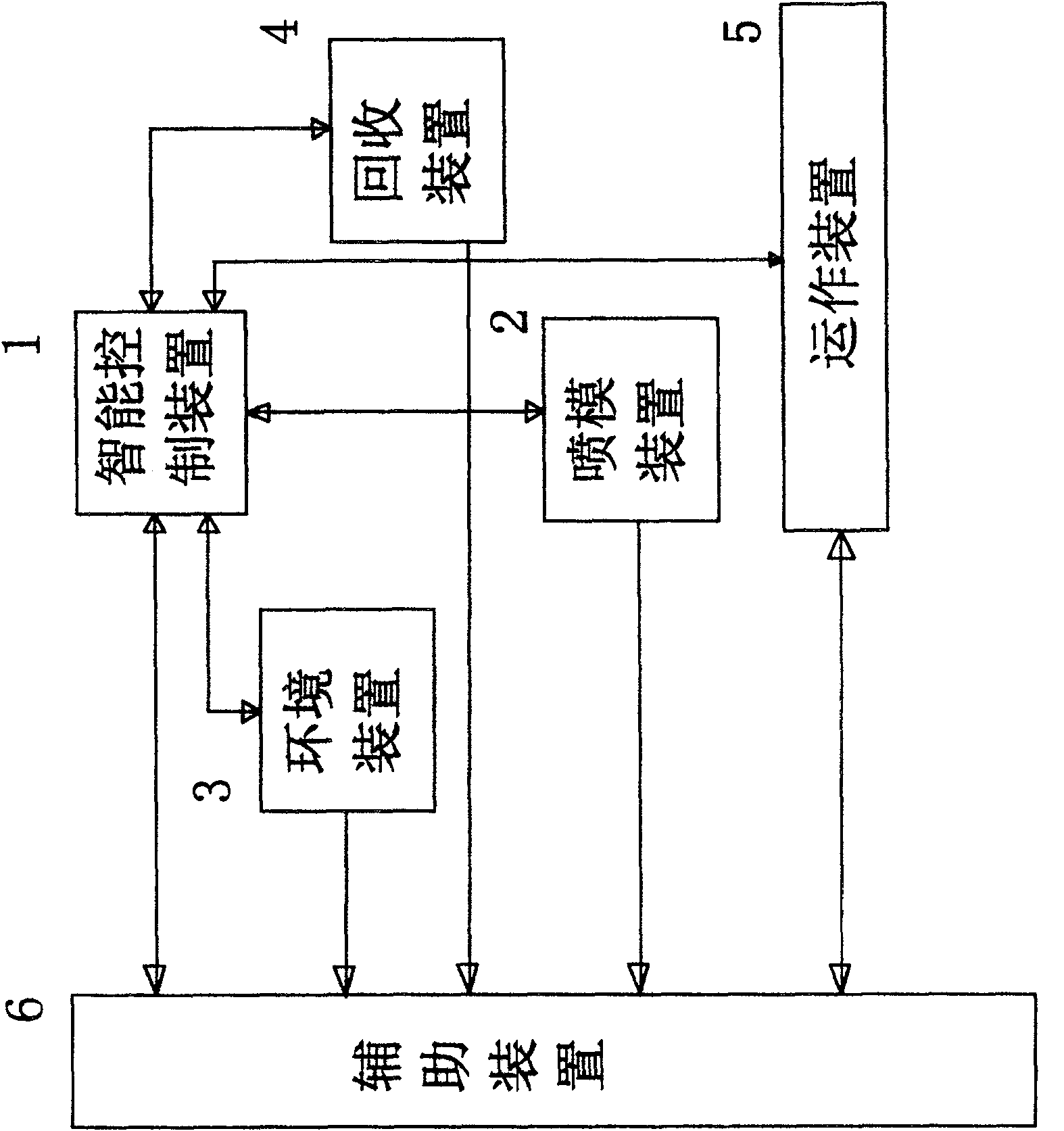

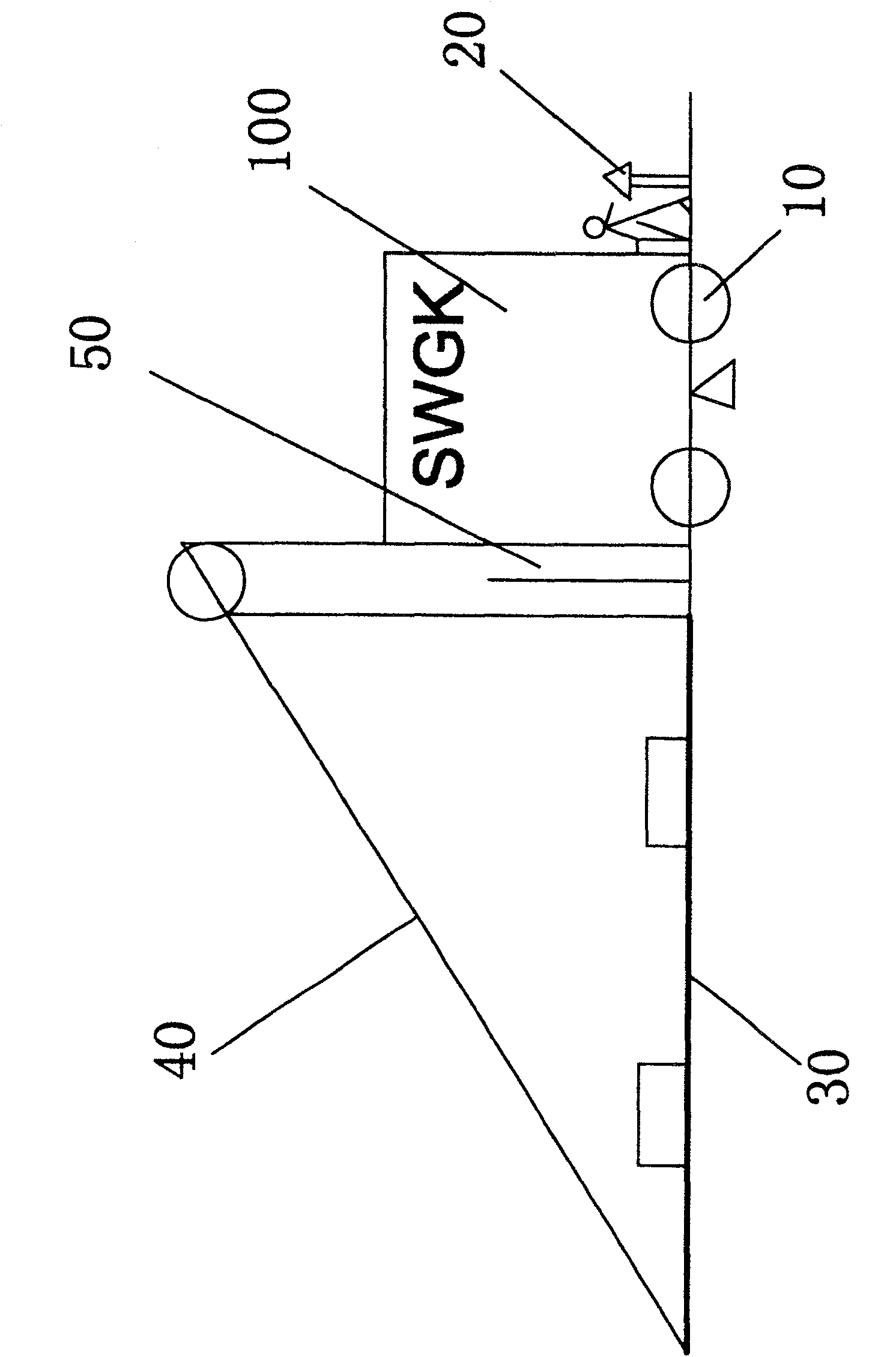

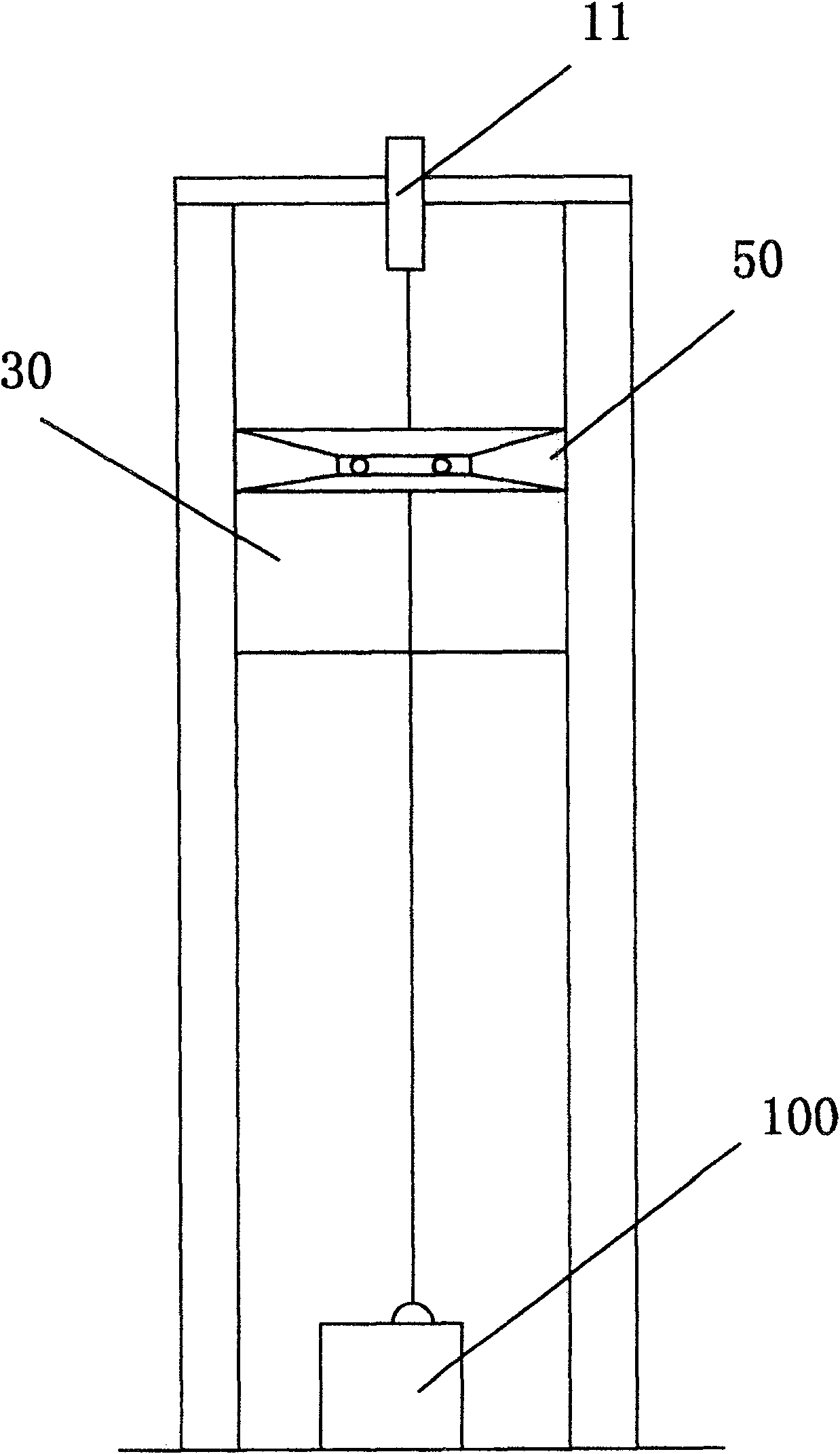

[0034] see figure 1 As shown, a kind of intelligent environment-friendly spray molding equipment of the present invention comprises:

[0035] The intelligent control device 1 includes a computer, software installed in the computer for controlling the mechatronic coordination of other devices, and several interfaces for electrical connection with other devices;

[0036] Spray molding device 2, comprising a spray foaming machine with a spray gun with a planar spray, a mold chamber that can foam the mixed material ejected from the spray gun to form a product, and the wall of the mold chamber is covered with a vulcanized silicone rubber film layer, and a viscosity indicator for testing the viscosity of the material; the viscosity indicator is connected to the computer through the input interface of the intelligent control device 1, and outputs a signal to the computer, and the spray foaming machine passes the intelligent The output interface of the control device 1 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com