Electric heating double helical plate eccentric separation pure steam generator

A centrifugal separation and double-helix technology, which is applied in the direction of steam generation, steam generation method, steam separation device, etc., can solve the problems of poor separation effect, poor steam quality, and inability to guarantee the quality of pure steam, and achieve fast production speed and good separation effect The effect of improving and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

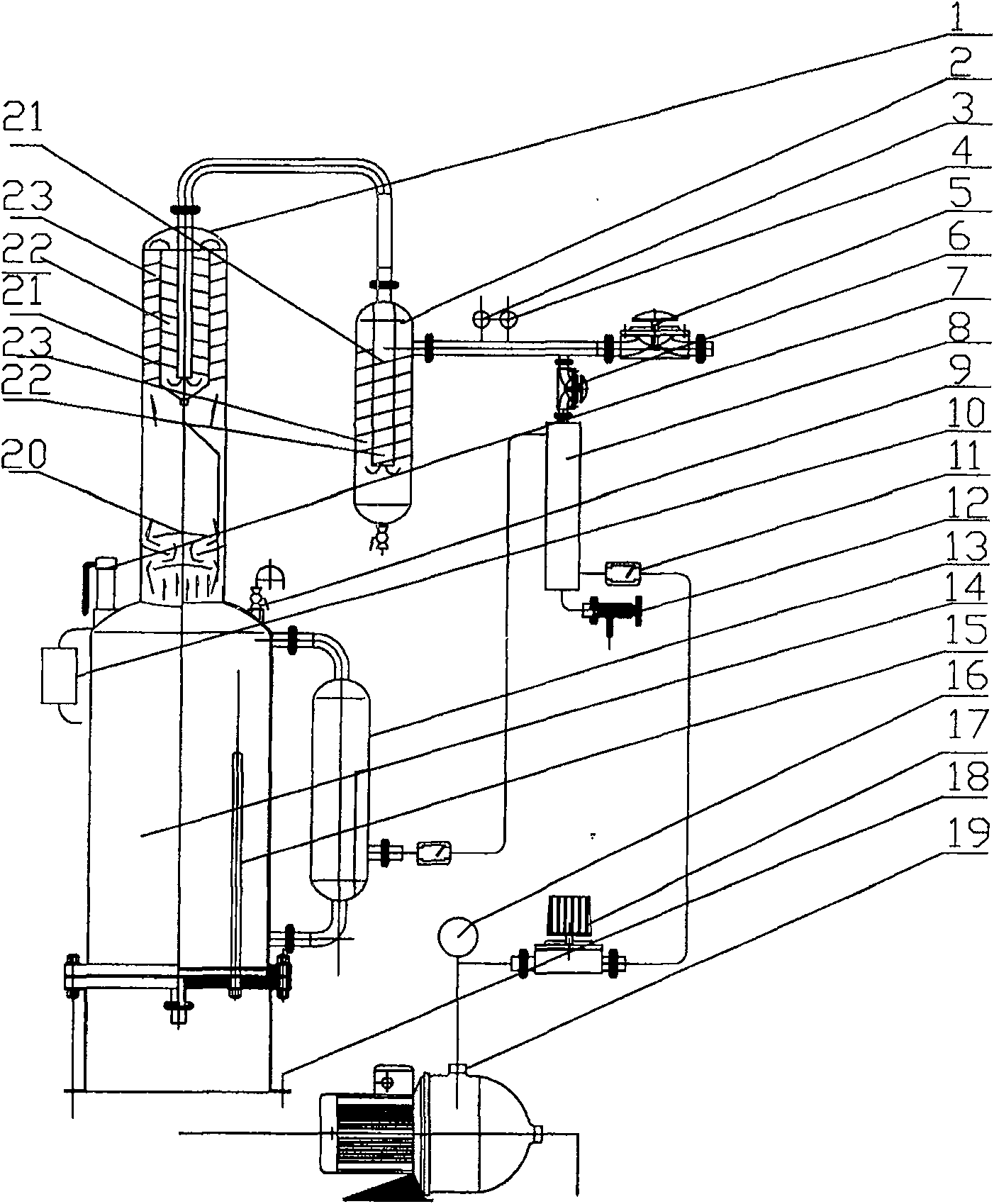

[0023] ZFCD-50 electric heating double-helix plate centrifugal separation pure steam generator, dimensions: length 1150 mm, width 150 mm, height 2450 mm; weight 250 kg; material: 316L stainless steel; pure steam output: 50 kg / hour; steam pressure : 0.3Mpa; raw material purified water consumption: 55 kg / hour; feed water pump (19) motor power 0.75KW. The purified water outlet pipe of the feed water pump (19) is connected to the buffer (13) through the condenser (8); the buffer (13) is connected to the double-screw plate centrifugal electric heater (14); The bottom of the device (14) is provided with an electric heating tube (15), the middle part of the double-helix plate centrifugal electric heater (14) is provided with a baffle (20), and the top is provided with a separation cylinder (21), an inner spiral plate (22), Outer spiral plate (23). The upper part of the separator (2) is provided with a separation cylinder (21), the inner wall of the separation cylinder (21) is provid...

Embodiment 2

[0025] ZFCD-100 electric heating double-helix plate centrifugal separation pure steam generator, dimensions: length 1150 mm, width 150 mm, height 2450 mm; weight 250 kg; material: 316L stainless steel; pure steam output: 100 kg / hour; steam pressure : 0.3Mpa; raw material purified water consumption: 110 kg / hour; feed water pump (19) motor power 0.75KW. The structure is the same as the first embodiment.

Embodiment 3

[0027] ZFCD-200 electric heating double-helix plate centrifugal separation pure steam generator, dimensions: length 1150 mm, width 150 mm, height 2450 mm; weight 560 kg; material: 316L stainless steel; pure steam output: 200 kg / hour; steam pressure : 0.3Mpa; raw material purified water consumption: 220 kg / hour; purified water pump (19) motor power 0.75KW. The structure is the same as the first embodiment.

[0028] The method of use of the present invention is simple. The purified water pump (19) is started, the purified water enters the system, the electric heating tube power supply is connected, the electric heating double-helical plate centrifugal separation pure steam generator starts to work, and pure steam is produced after 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com