Oil field blowout preventer injection adhesive-coating vulcanization device and vulcanization formation method thereof

A blowout preventer and glue-covering technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of injection pressure loss of products that cannot be continuously injection-molded, and achieve product compactness, uniformity, and quality Excellent, good quality accuracy and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

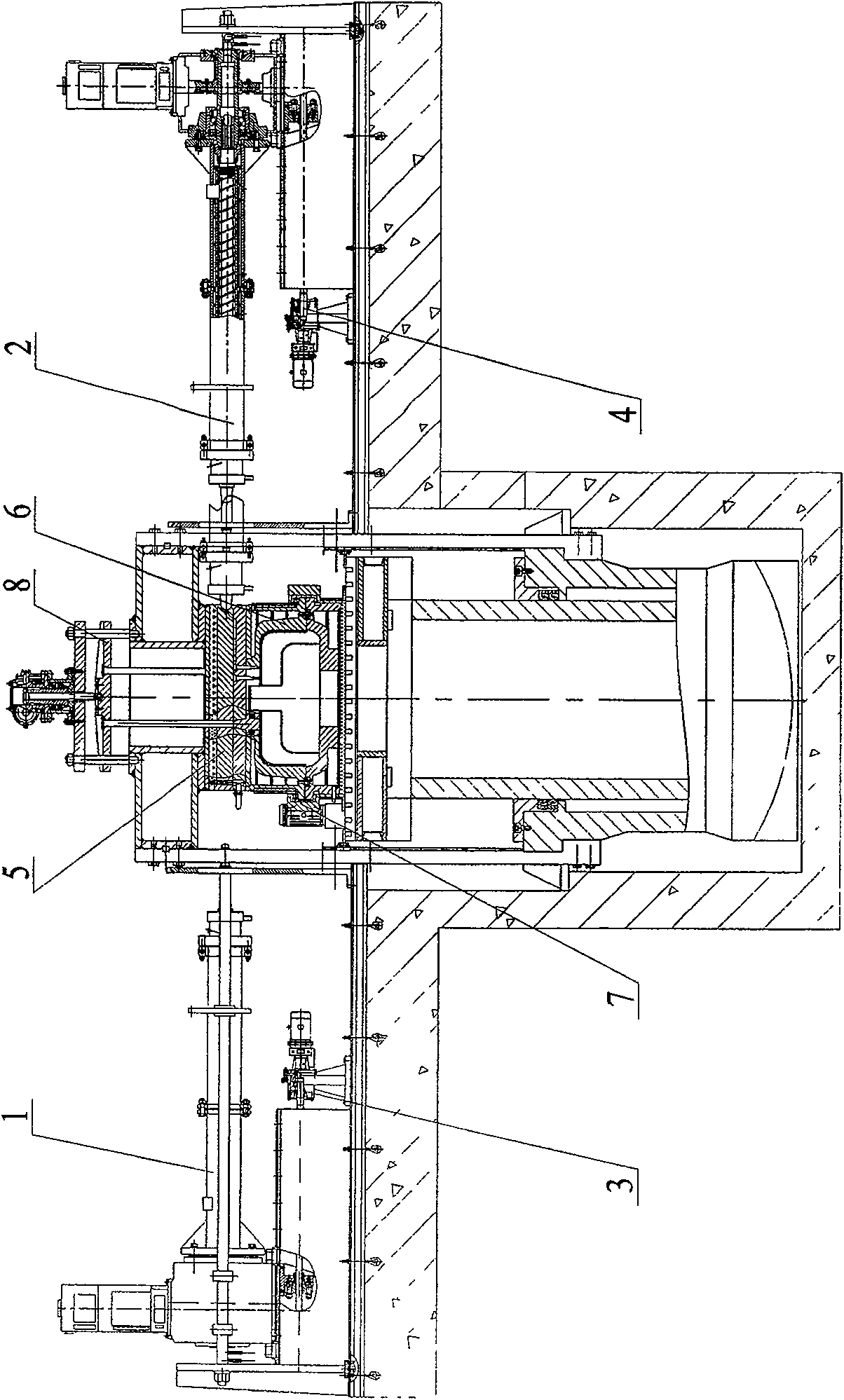

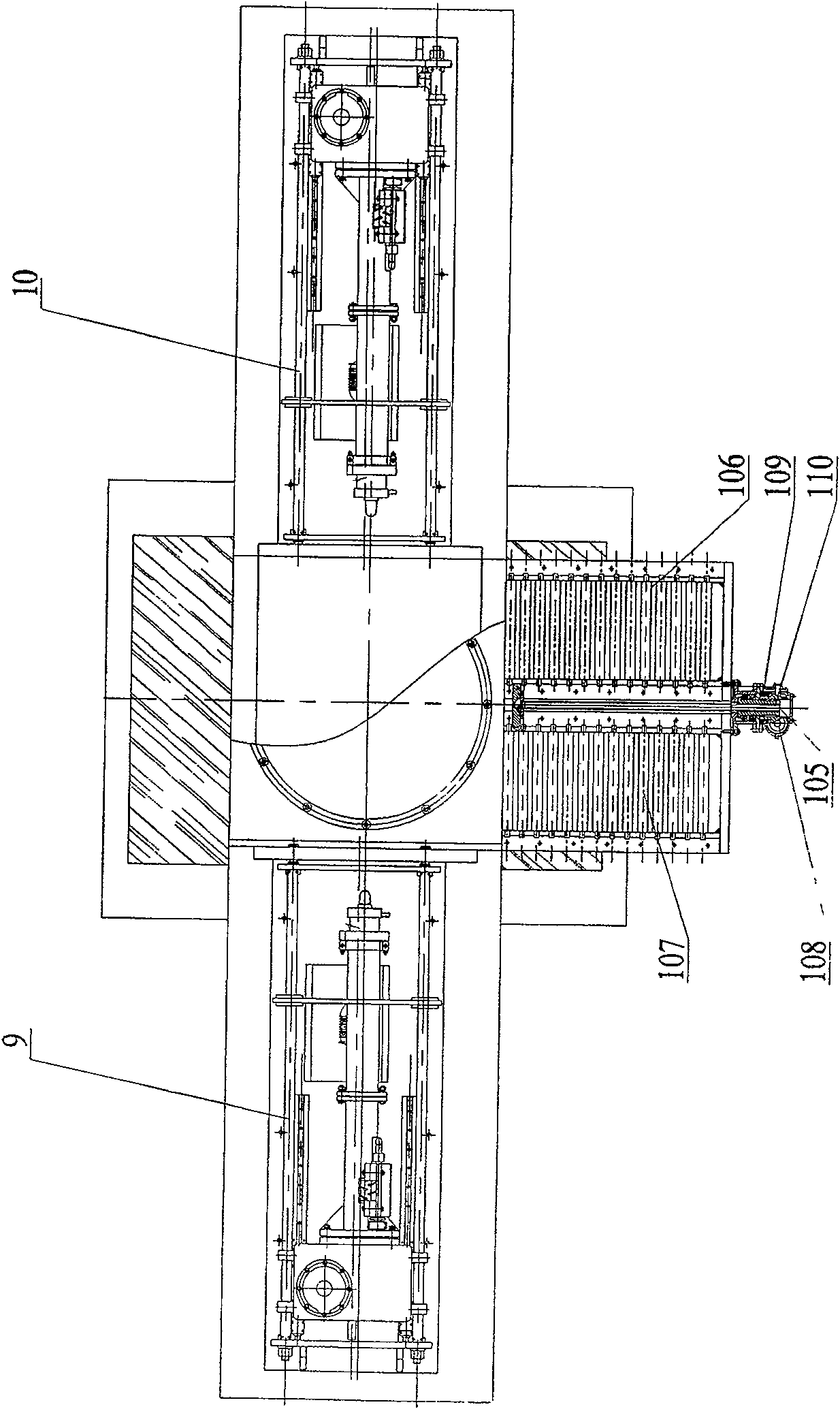

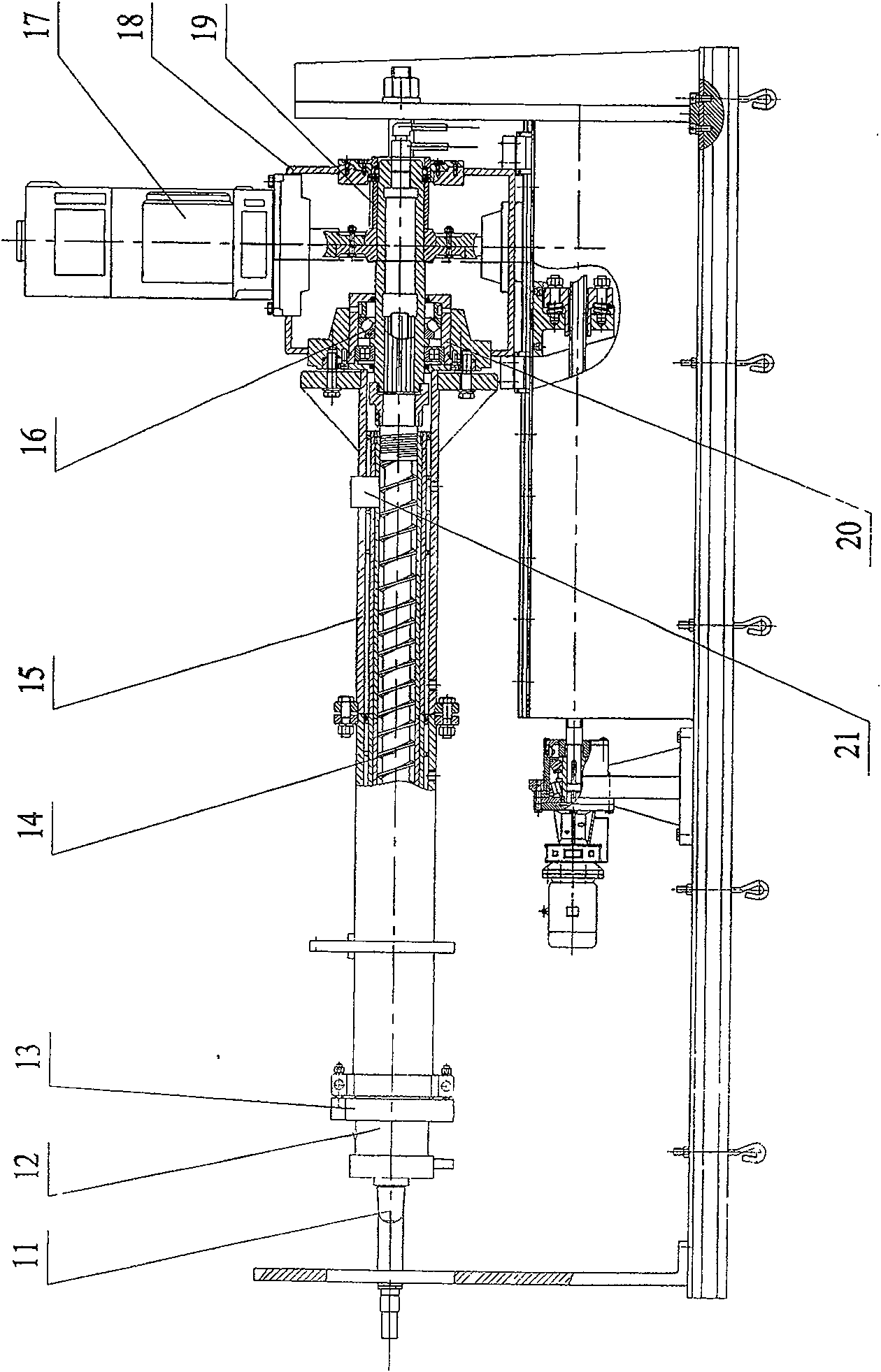

[0045] The main structure of this embodiment includes left and right injection machines 1, 2, left and right pressing devices 3, 4, vulcanizing machine 5, mold system 6, locking ring device 7, demoulding device 8 and left and right guide frame 9, 10. The injection machine has a left injection machine 1 and a right injection machine 2, the structure is exactly the same, and the installation direction is opposite. The injection machine 2 includes a worm gear reduction box 18, and the main motor 17 is installed on the reduction box 18. The main shaft 19 of the box is a hollow shaft sleeve. The hollow shaft sleeve is installed in the bearing housing 20 with the bearing 16 installed. The bearing housing 20 is installed on the left end of the reduction box 18. The screw 14 constitutes the plasticizing and injection system. A screw meshing feeding device 22 is installed at the feeding port 21 of the barrel 15. A machine head 13 is installed at the left end of the machine barrel 15. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com