Method for forming capacitor and random access memory unit

A random access memory and capacitor technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of reducing the surface area of capacitors, reducing capacitance, etc., to improve capacitance, increase surface area, and uniform atomic size. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

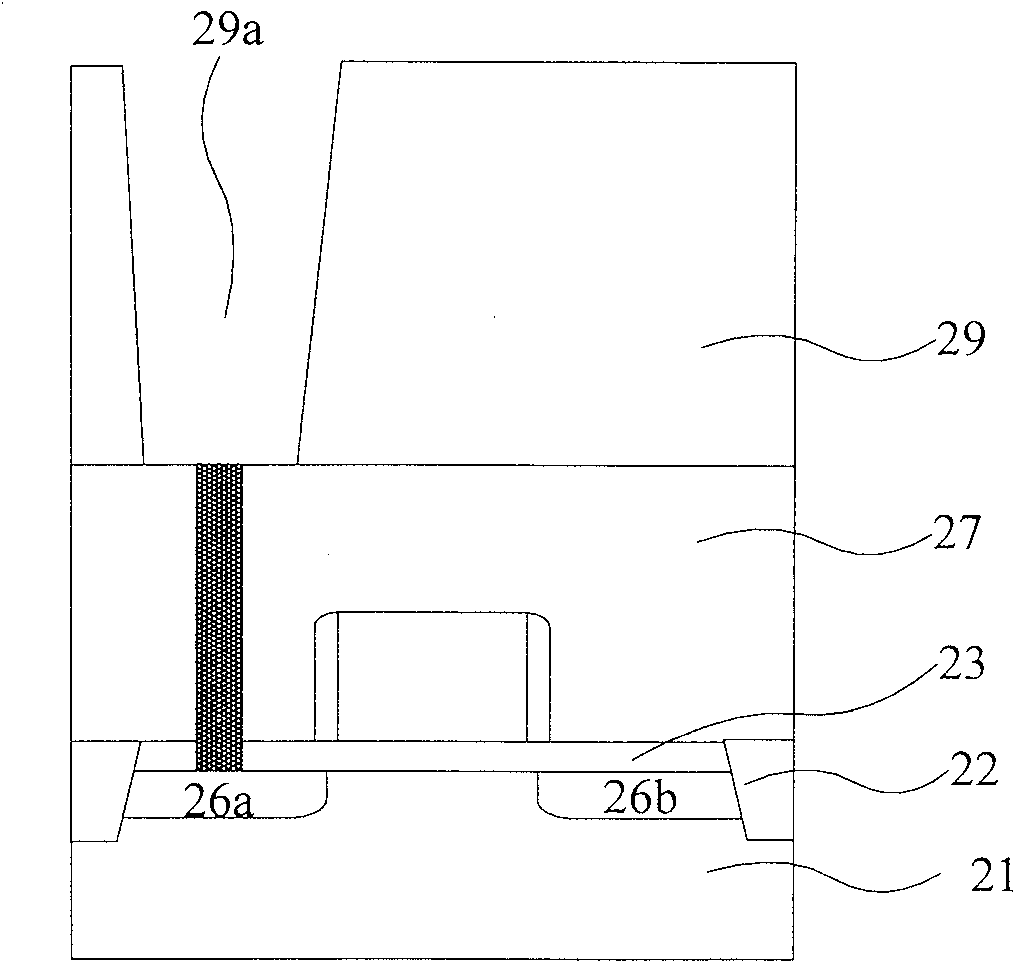

[0039] This embodiment provides a method for forming a capacitor, refer to the attached Figure 7 The process flow chart shown includes the following steps: execute step S301, forming uniform discrete atomic islands on a semiconductor substrate with an interlayer dielectric layer and a polysilicon layer in sequence; execute step S302, perform an annealing process, and make the atoms The island reacts with the polysilicon layer to form discrete spherical particles; perform step S303, use the discrete spherical particles as a mask, etch the polysilicon layer and the interlayer dielectric layer, and form grooves in the interlayer dielectric layer; perform step S304, A first conductive layer, an insulating dielectric layer and a second conductive layer are sequentially formed on the interlayer dielectric layer inside and outside the groove.

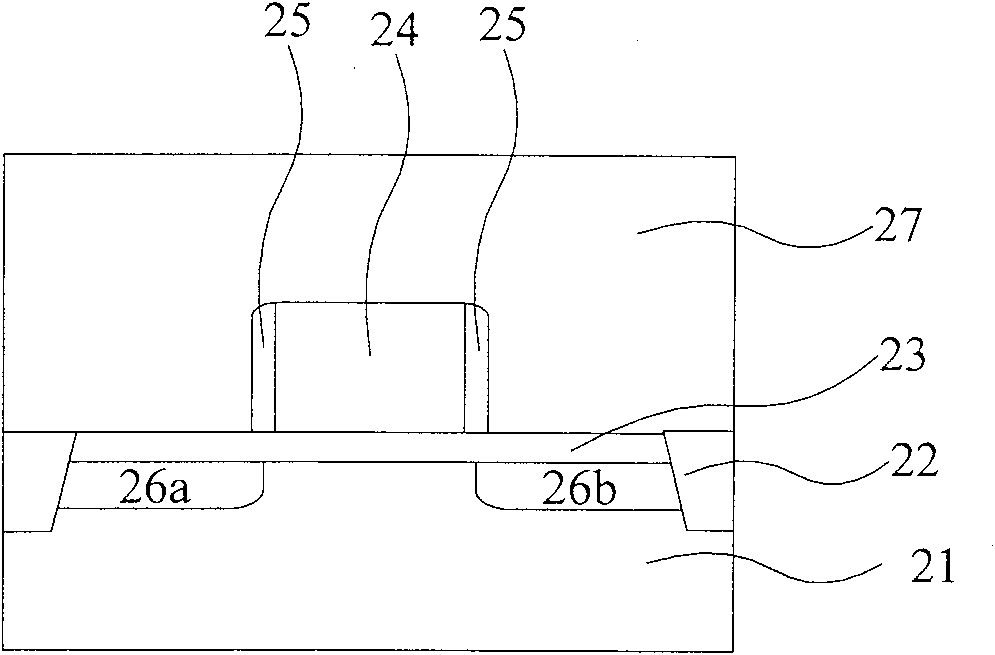

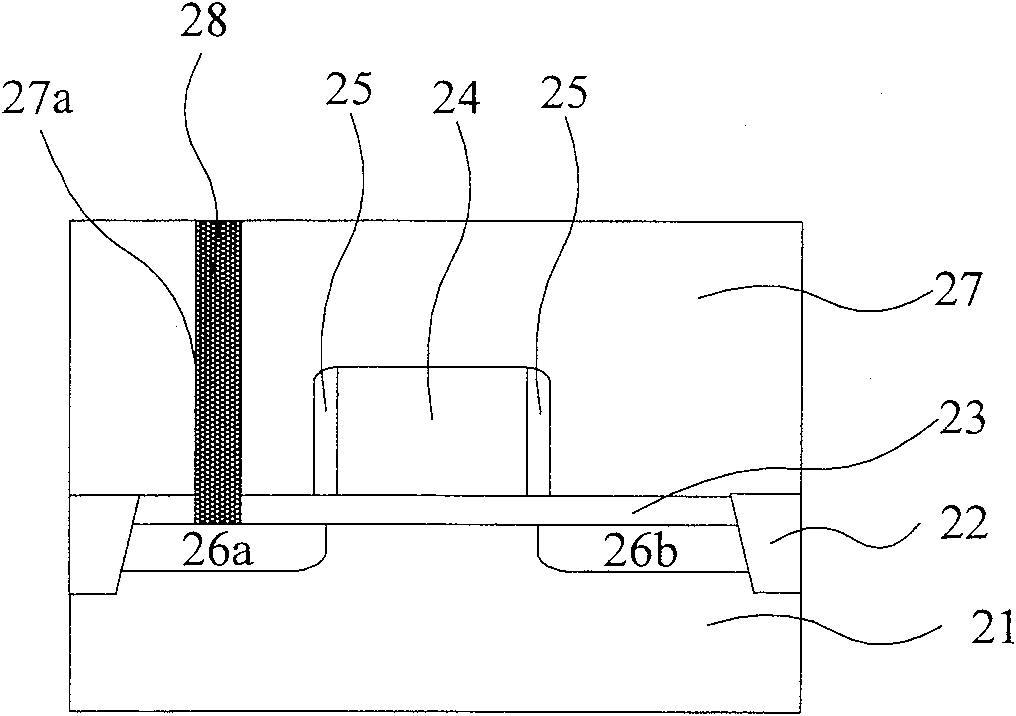

[0040] Figure 8 to Figure 12 It is a structural schematic diagram of an embodiment of forming a capacitor in the present invention. like ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com