Medical tower crane rotary arm

A technology of slewing arms and slewing arms, which is applied in the field of slewing arms, can solve problems such as heavy weight of the workbench, potential safety hazards, shaking, etc., and achieve the effects of relatively stable movement, reliable positioning, and smooth and slow movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

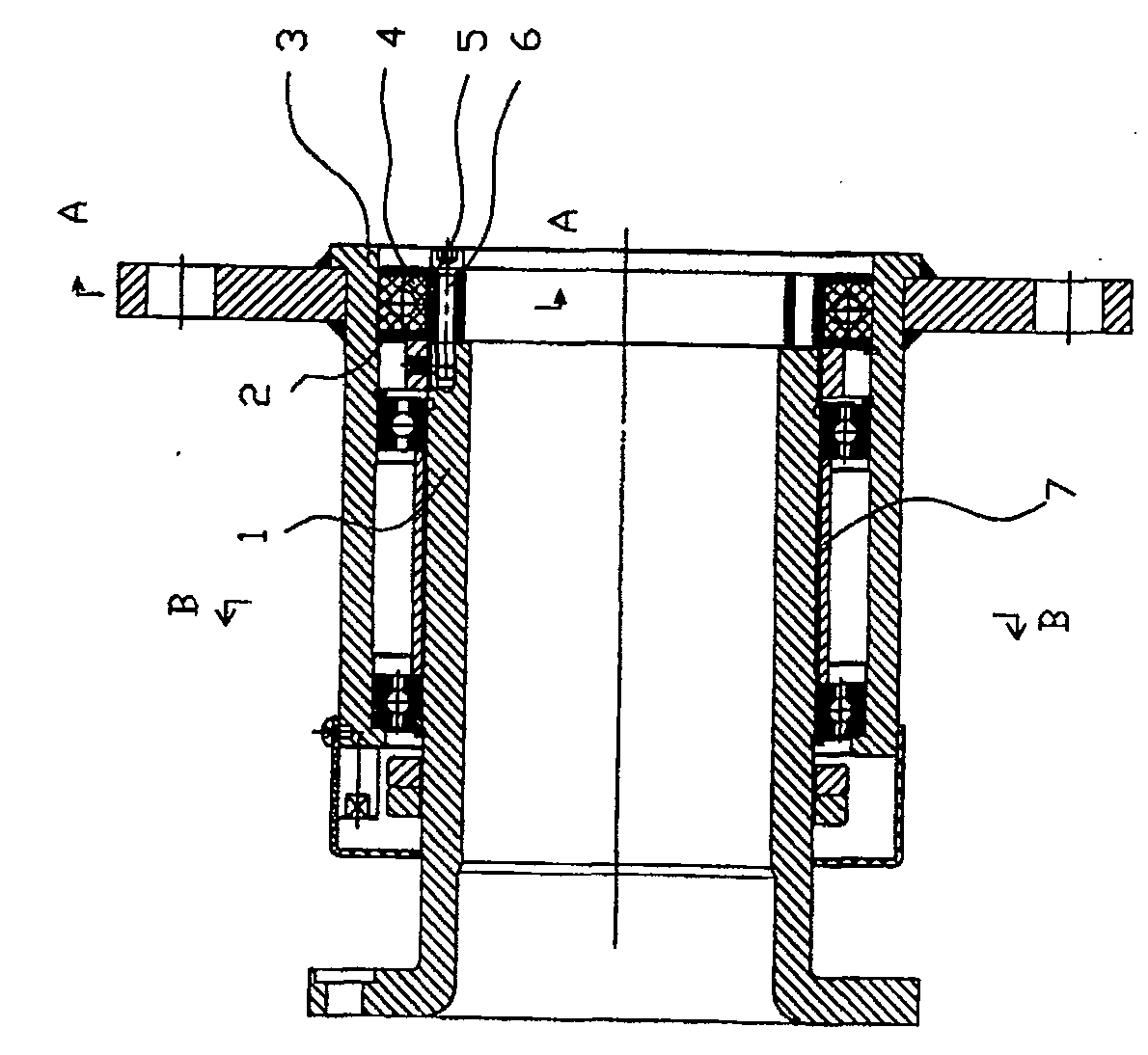

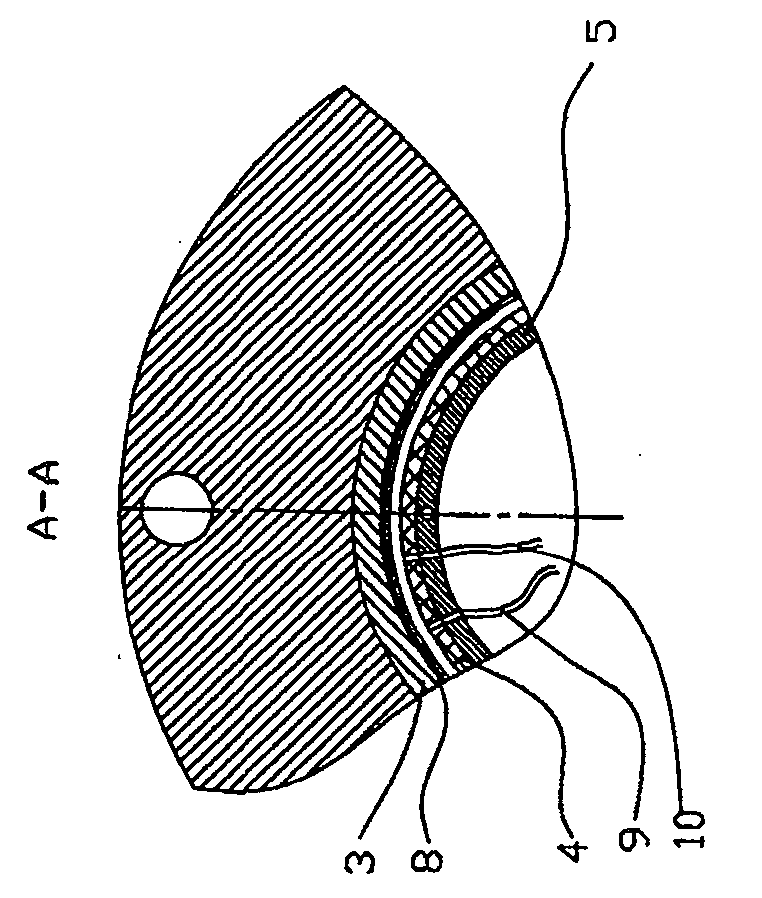

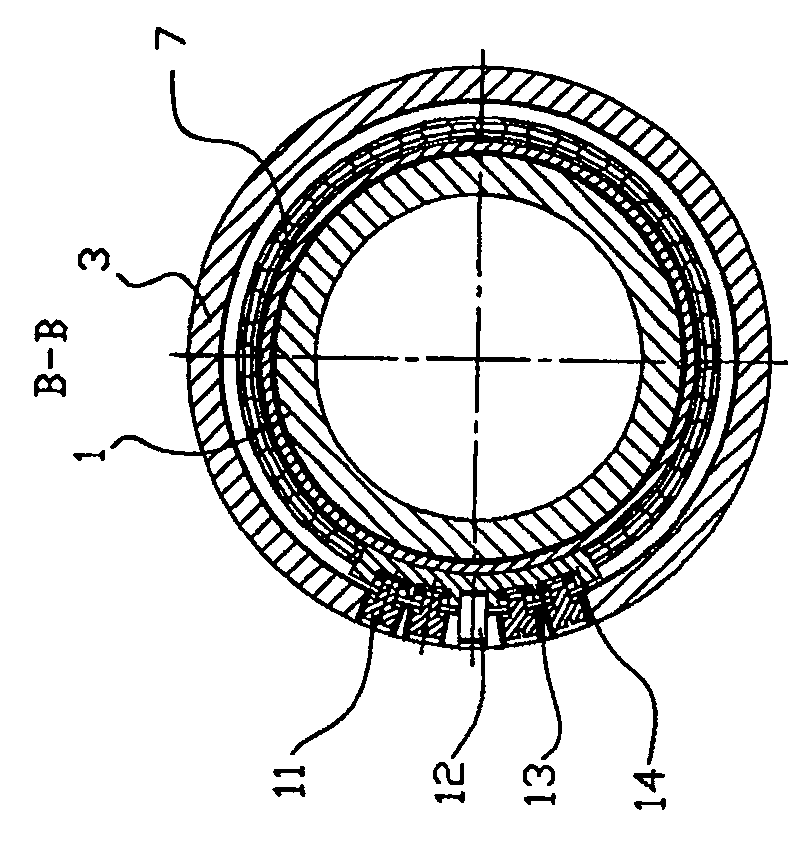

[0017] The present invention comprises the arm cover 3 and the hollow arm 1 which is arranged in the arm cover 3 and can rotate freely. between dampers.

[0018] Brakes such as figure 1 , 2 , consisting of a brake disc 5 arranged on the end face of the hollow arm 1, an air pressure expansion ring 4 arranged on the outer ring of the brake disc 5, an air source, and an air pressure control device for the expansion ring 4; the brake disc 5 is coaxial with the hollow arm 1 , is fixedly connected by connecting screw 6, and its outer end is located in the 3 pockets of the arm cover; the air pressure expansion ring 4 is fixedly connected on the surface of the brake disc 5 edge; the air pressure expansion ring 4 is connected to the air source and the air pressure control device through the trachea. In order to make the positioning of the air pressure expansion ring 4 reliable, a circle of grooves 2 is provided on the edge of the brake disc 5, and the air pressure expansion ring 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com