Water resistance tree medium voltage insulated cable material and cable

A technology for insulating cables and anti-water trees, applied in plastic/resin/wax insulators, organic insulators, etc., to achieve the effect of perfecting the crystal structure, avoiding water condensation, and prolonging the growth time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

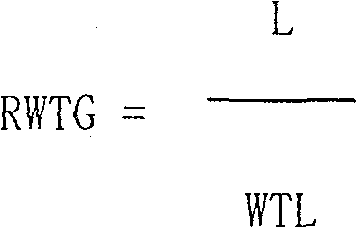

Image

Examples

Embodiment 1

[0040] Example 1: Preparation of organic montmorillonite by microwave

[0041] Add 25g of montmorillonite and 750g of deionized water, raise the temperature to 75 degrees, add dropwise an aqueous solution containing 12g of dinonyldimethylammonium bromide at a concentration of 20%, and treat it with microwave for 7 minutes every 45 minutes after the addition is completed , stirred for 5 hours, filtered with suction, washed the precipitate with deionized water, silver nitrate (0.1mol / L) could not detect bromide ions, dried in vacuum to constant weight, ground and sieved through 200 meshes to obtain organic modified montmorillonite earth.

Embodiment 2

[0042] Example 2: Preparation of Medium Voltage XLPE Insulated Cable Material

[0043] The composition of the formula in parts by weight of medium-voltage XLPE insulated cable material:

[0044] Low-density polyethylene 100 parts

[0045] Dicumyl peroxide 1.8 parts

[0046] 0.6 parts of bis-tert-butylperoxycumene

[0047] Tris(2,4-di-tert-butylphenyl)phosphite 0.1 parts

[0048] 0.3 parts of 4,4'-thiobis(3-methyl-6-tert-butylphenol)

Embodiment 3--9

[0049] Examples 3-9: According to Example 2, the formula of the compound anti-water tree growth agent was changed, and the anti-water tree medium-voltage XLPE insulating cable material was prepared, as shown in Table 1:

[0050] Table 1. The medium-voltage insulating cable material prepared by adding different anti-water tree growth agents to the basic formula of Example 2

[0051] Example

hydrogenated glycans

Organic Montmorillonite

maleic anhydride graft

wxya

2

--

--

--

--

6.2

3

0.5

--

--

--

15.6

4

--

0.1

--

--

11.4

5

--

--

7

--

15.2

6

--

--

--

0.1

9.5

7

0.5

0.1

7

0.1

24.5

8

0.6

0.1

6

0.1

24.3

9

0.5

0.2

6

0.1

24.6

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com