Optical device package and optical semiconductor device using the same

A technology of optical components and components, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, semiconductor lasers, etc., can solve the problems of reduced thermal conductivity of molded resin, increased high-frequency transmission loss, and reduced optical characteristics, etc., to reduce optical Reduced characteristics, good high-frequency characteristics, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

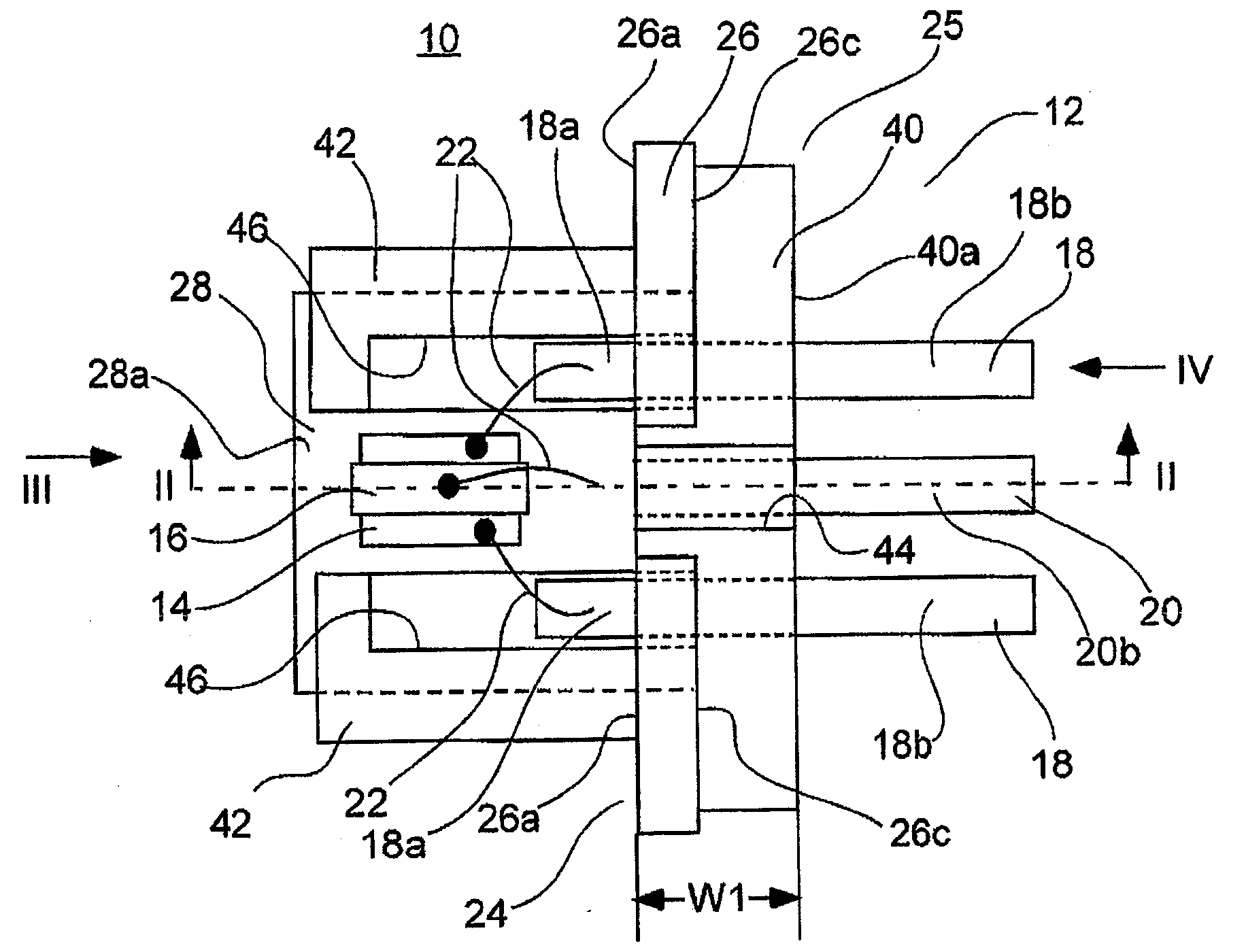

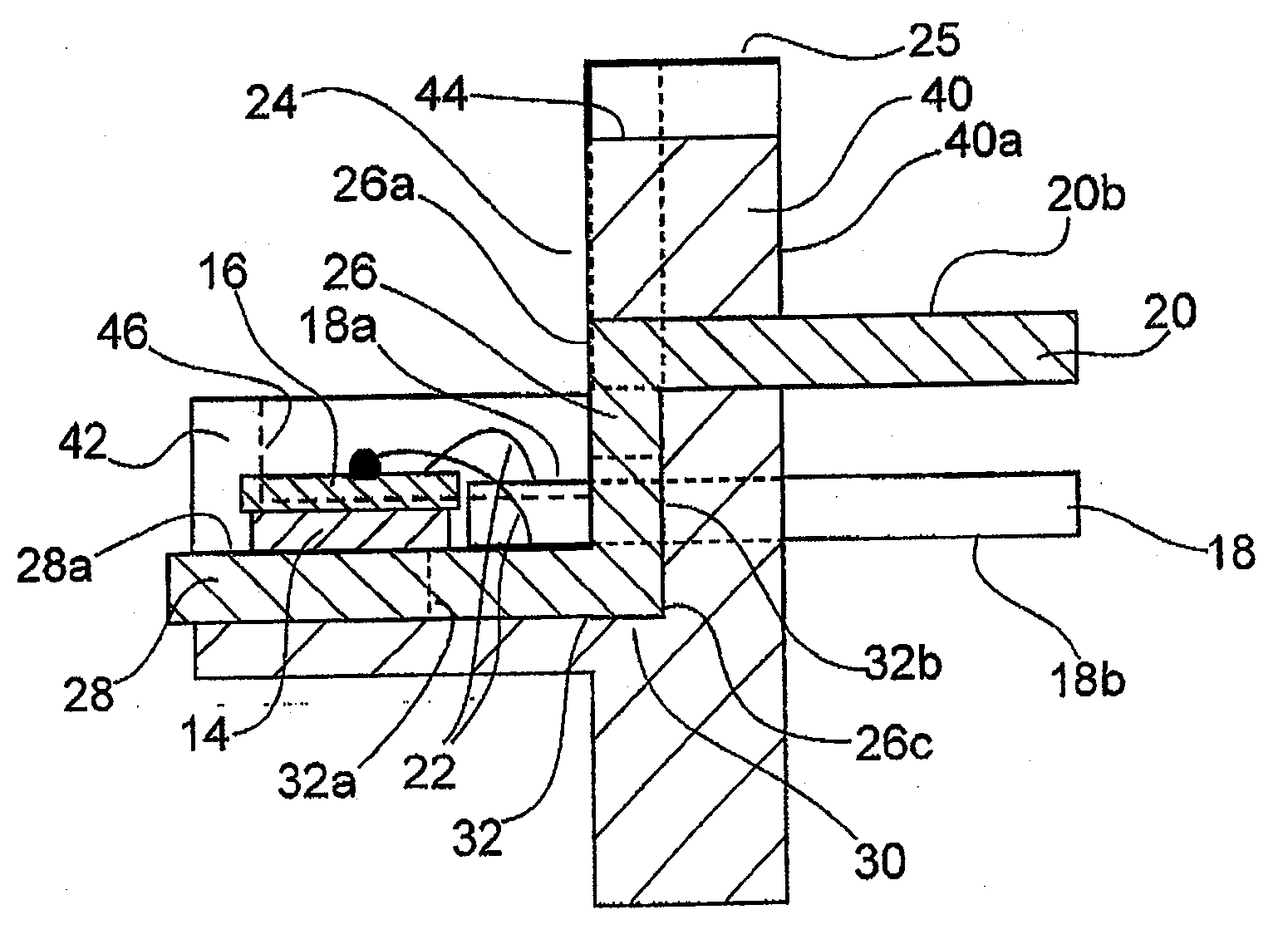

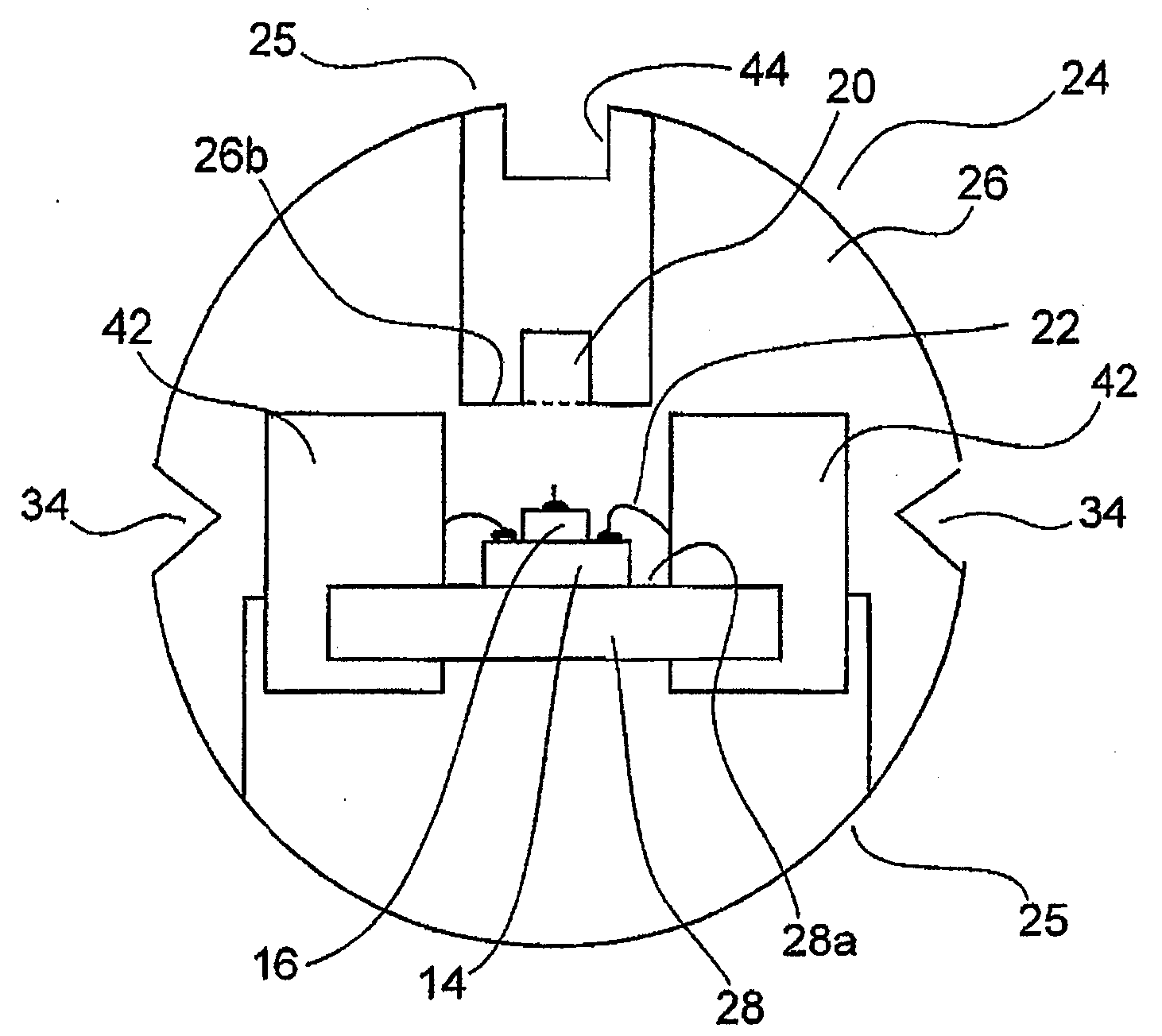

[0035] figure 1 is a plan view of an LD device according to one embodiment of the present invention. figure 2 yes figure 1 A cross-sectional view in the direction of the arrow in the II-II cross-section of the shown LD device. image 3 From figure 1 Front view of the LD device viewed in the arrow direction III. Figure 4 From figure 1 Bottom view of the LD device viewed in the arrow direction IV. Figure 5 It is a perspective view showing the positional relationship between the metal base and the lead electrodes of the LD device according to one embodiment of the present invention. Figure 6 is a perspective view of an LD device according to one embodiment of the present invention. In the drawings, the same symbols represent the same or corresponding components.

[0036] Such as figure 1As shown, the LD device 10 is composed of an LD assembly 12, an LD chip 16 installed in the LD assembly 12 by an auxiliary support (submount) 14, an electrode (not shown) connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com