Method for treating surface of phosphor, phosphor, light-emitting device, and illumination device

A technology of surface treatment and phosphor, applied to the surface coating liquid device, after treatment, luminescent material, etc., can solve problems such as degradation, and achieve the effect of improving the reliability of moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

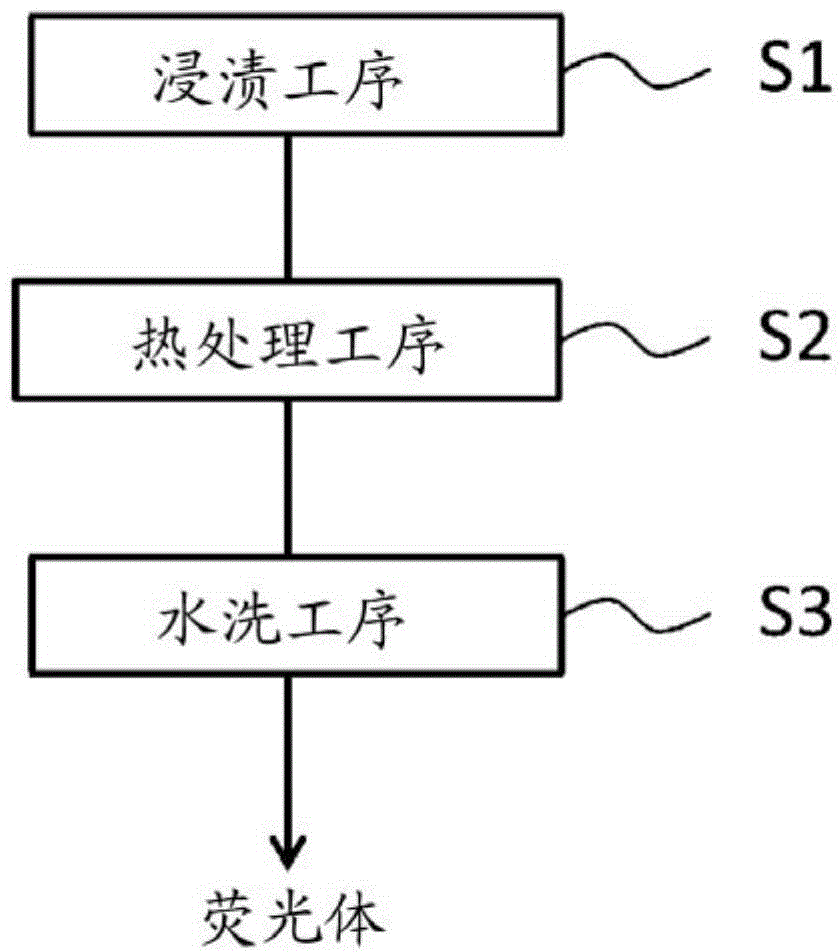

Method used

Image

Examples

Embodiment

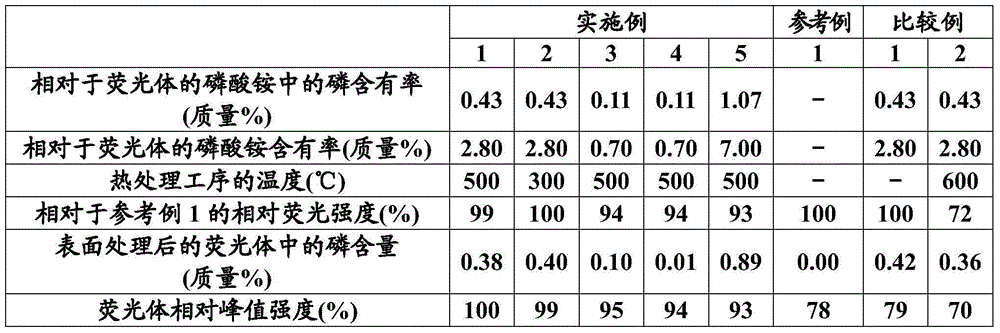

[0041] Examples and comparative examples of the present invention are listed below, and the effects of the present invention will be described with reference to Table 1. FIG.

[0042] The phosphors of the surface treatment methods of the phosphors of Examples and Comparative Examples are host crystals with (Sr, Ca)AlSiN 3 Phosphors with substantially the same crystal structure were produced by the following production method, and are Reference Example 1 in Table 1.

[0043] [Manufacturing method of phosphor]

[0044]As for the raw material of the phosphor, 52.2 mass % of α-type silicon nitride powder (SN-E10 grade manufactured by Ube Industries, Ltd.), 45.8 mass % of aluminum nitride powder (E grade manufactured by Tokuyama Corporation), 2.0 Mass % europium oxide (RU grade manufactured by Shin-Etsu Chemical Co., Ltd.). These raw materials were mixed with a ball mill to produce a mixed raw material. For ball mill mixing, a nylon tank and silicon nitride balls were used, and ...

Embodiment 2

[0058] In the surface treatment method of the phosphor in Example 2, except that the temperature of the heat treatment step was set to 300° C., using the same method and conditions as in Example 1, the above-mentioned host crystal had the same (Sr, Ca)AlSiN 3 Phosphors having substantially the same crystal structure as the crystals are surface-treated.

Embodiment 3

[0060] In the method for treating the surface of the phosphor in Example 3, except that the amount of triammonium phosphate trihydrate added to the phosphor was 0.70% by mass (the phosphorus content relative to the phosphor was 0.11% by mass), Using the same method and conditions as in Example 1, the above-mentioned host crystal has the same properties as (Sr, Ca)AlSiN 3 Phosphors having substantially the same crystal structure as the crystals are surface-treated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com