Method for producing low carbon ferromanganese

A technology of low-carbon ferromanganese and carbon manganese, which is applied in the field of smelting low-carbon ferromanganese, can solve the problems that it is difficult to produce low-carbon ferromanganese and micro-carbon ferrochromium, achieve high voltage, fast desiliconization speed, overcome growth carbon effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

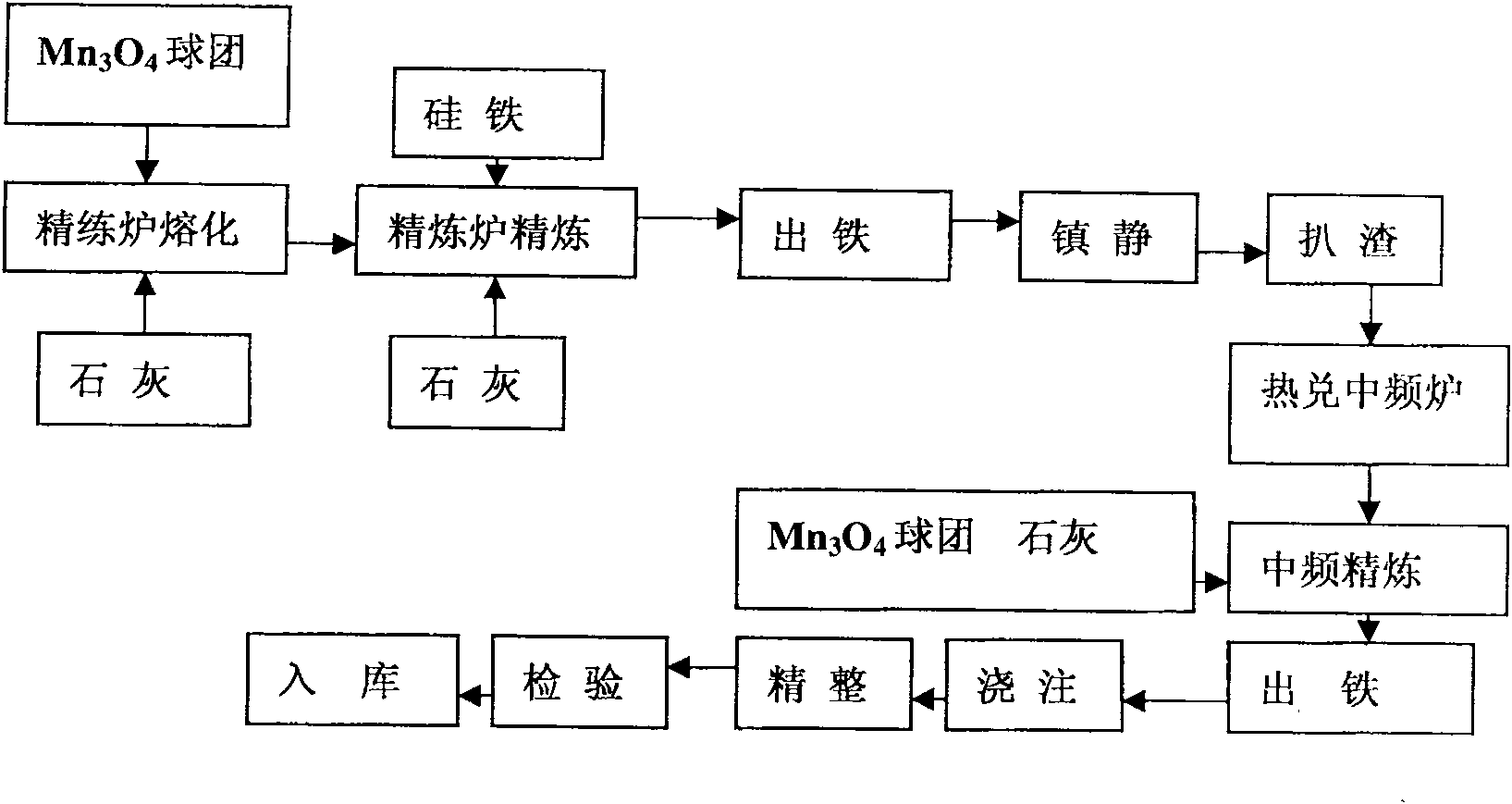

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention are described in further detail below through examples.

[0025] Technical scheme of the present invention is made of following method steps:

[0026] 1. Preparation of Mn 3 o 4 . According to manganese oxide ore: liquid phase reducing agent: sulfuric acid = 1: 0.1-0.2: 0.5-0.6 (weight ratio), mix manganese oxide ore and liquid phase reducing agent such as molasses or starch, leach with sulfuric acid, add alkali to precipitate and remove iron, and wash , to prepare Mn 3 o 4 . Its chemical composition is: Mn≥69%, Fe≤0.05%, P≤0.05%, S≤0.03%, Sn≤0.001%, Pb≤0.001%.

[0027] 2. Raw material preparation. Ferrosilicon is crushed to a particle size of ≤20mm, quicklime containing CaO≥85% is crushed to a particle size of 8-50mm, and artificially synthesized Mn 3 o 4 pelletized and dried;

[0028] 3. Smelting low silicon manganese silicon alloy

[0029] Furnace charge ratio according to ferrosilicon: Mn 3 o 4 Pellets: l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com