Chip oxygen sensor and its preparation method

An oxygen sensor, a chip technology, applied in the field of automotive chip zirconia oxygen sensor and its preparation, can solve the problems of difficulty in meeting exhaust emission requirements, slow response speed, complex structure, etc., to reduce poisoning failure, The effect of fast response speed and faster response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

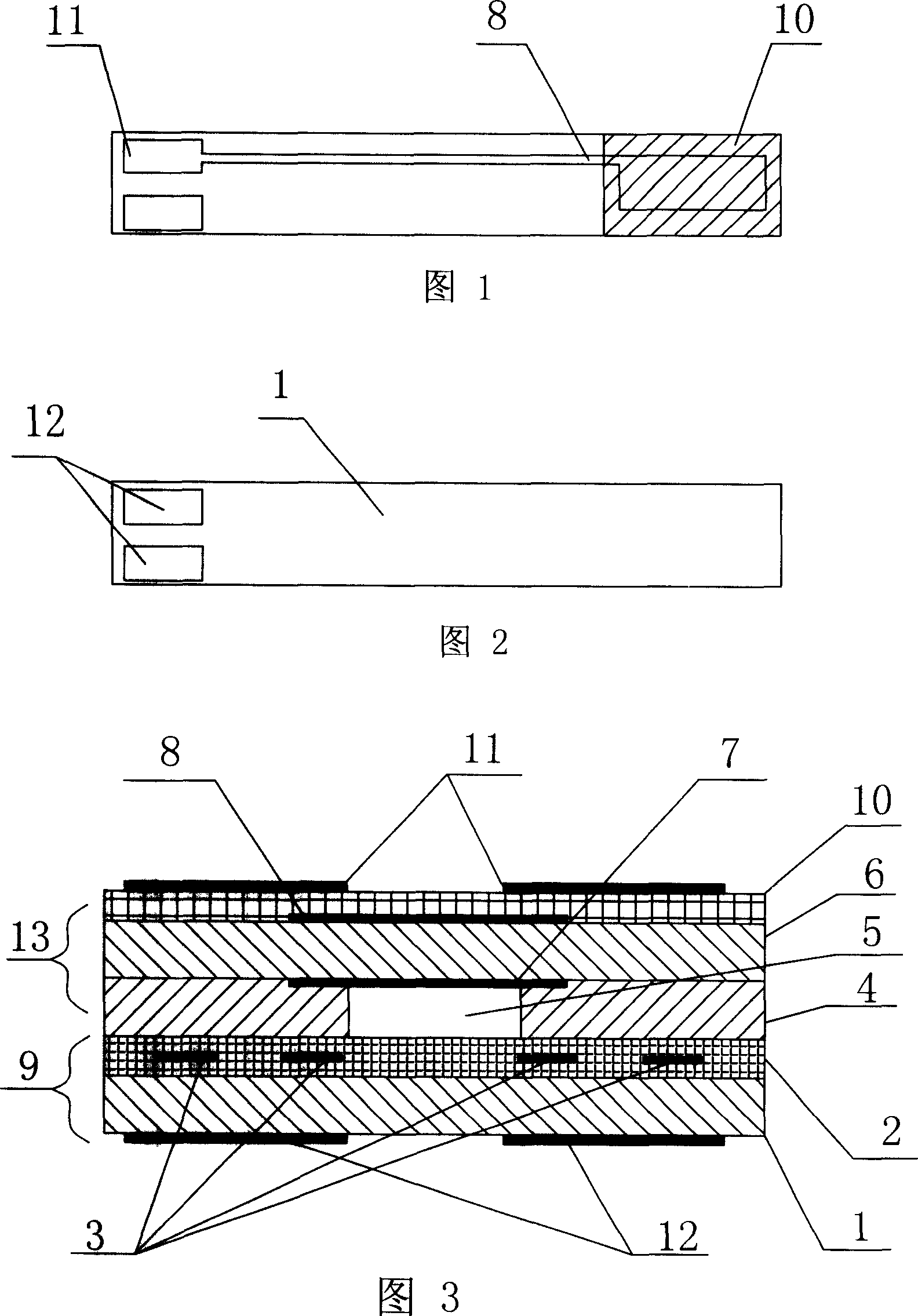

[0032] With reference to Fig. 1, provide a kind of chip type oxygen sensor and preparation method thereof, chip type oxygen sensor comprises heater (9) and oxygen sensitive probe (13), and heater (9) comprises heater substrate (1), is located at heating The insulating layer (2) on the upper part of the base body (1) and several heating bodies (3) arranged inside the insulating layer (2), the oxygen sensitive probe (13) includes the reference gas channel body arranged on the upper part of the heater (9) (4), the zirconia sensitive substrate (6) arranged on the upper part of the reference gas channel body (4), the external electrodes (8) and the internal electrodes (7) respectively arranged on the upper and lower surfaces of the zirconia sensitive substrate (6), each The two ends of the heating body (3) respectively extend outward and converge to form two conductive pins (12) at the lower part of the heater base (1), and a porous protective layer (10) is provided on the upper sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com